Great idea. We don’t want it to be actually air tight. If you put hot charcoal in a drum and seal it with a lid and sealing ring it will create a vacuum and crush the barrel. I had to warn my friends in Rwanda about this after seeing a picture of this problem encountered by a fellow charcoal maker.

Jeff, is that an old H?

I put the lid on then a cement block goes on top. Seems to, been doing that for some years now.

That is an old M. Had two of them for a long time but they are gone now.

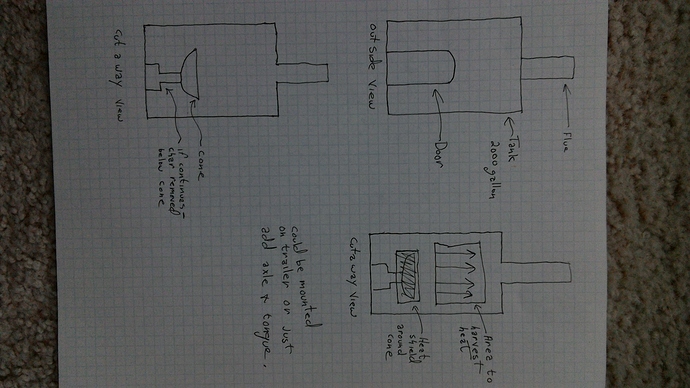

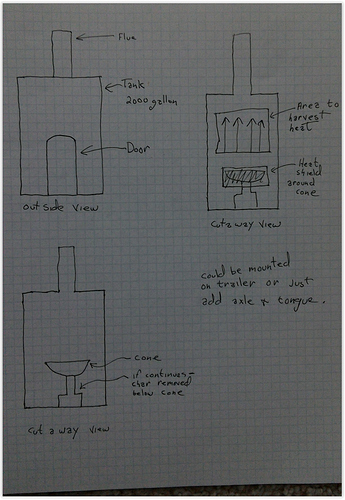

Dug that 2000 gallon tank out and stood it up. Later cut two or three slits, weld hinges over the slits then cut out the rest of the door. Then the cone kiln can move in.

the charcoal grinder is on the trailer right side of tank.

I’m really interested in this system made from “obtainium.” The tank looks tall enough to cut in half and make a cover for each of your bowls.

Bruce, I better start eating my Wheaties if I want to pick half of that tank.

Check out the drawing below.

The photo some how got rotated to the right, oops.

Hi Jeff,

I used the Gadwin Print Screen program (free download) to copy and rotate your pic. The program will copy (capture) anything on the screen, then you can do what you will with it ( copy, print, rotate, resize, etc). It gives the option of where to save the screen captures.

Pepe

Thanks Pepe, I’ll have to remember that.

With the size of this cone I have some doubts that it needs to be continuous. I would need to run three shifts! However it would be nice to drain the charcoal out of the bottom and no shoveling it out the top or no tilting the cone to dump out the charcoal. Well, tilt dumping would be better than shoveling. On the other hand, draining out the bottom would be the least dusty.

Never pass up any good lawn tables.

Self angling.

Add guides.

That charcoal was from this winters out door wood boiler co lots of ash.

I can see making a rotating pan screen out of that table someday.

Next into the grinder.

I normally put charcoal fines in the garden as biochar. In Rwanda our charcoal is all fines from crop waste. With these fines, we make large cooking briquettes 4" round X 3" high. Now I need to make some tiny briquettes to run a gasifier in Rwanda. Today I tried using a sausage stuffer to extrude small diameter charcoal–no go. Then I tried a heavy duty meat grinder with sausage stuffer attachment. Still poor results–the charcoal has to be too wet to extrude. Only makes soft irregular sized “briquettes.” I finally went extremely low tech with a 1/2" rod and a 1/2" pipe.

I used the pipe like a cookie cutter. Pushed down into a 1" thick pile of moist charcoal with 5% binder. Place over nylon window screen (lets water squeeze out easier) on a board and bang the rod in the pipe up and down a few times. Then push out the pellet. Voila, carbonite. Labor intensive, but labor is cheaper than importing gasoline to a remote village in a landlocked country. Now to make enough for a gasifier test run.

Hi Bruce, what was the 5% binder you used In your mix?

Bob

Hi Bruce,

Don’t put them in a charcoal gasifier, the tar will hurt… ( The binder is a problem )

But maybe you could cure them in a retort ( bake them ) ?

I am fixing my small oven to do the same and will try the recipe from Francois ( Tar with carbon residue )

A good source for Carbon: biomass boilers, the ashes contains a huge % of unburned carbon…

,

,

Koen glad to tell you that our boilers Biomasses that we build in the ashtray, we found only silicic, sand in sum, at least on the boiler that for three years that I developed in this company, if there is carbon in the ashes, it is a waste and a bad adjustment of the boiler, one is lower than 250 in CO and 350 in NOX according to the humudity of the wood. I am very left of the photo.

here is the patent link for a carbonite manufacturing system, an axis rotates with a worm, variable pitch and abrasion resistant which compresses the mixture and produces two rods, cut by a steel bar into end of the axis to a desired length.

Hi Bob,

I work with sanitation in Africa so you can guess what the binder is. We pasteurize/hygienate feces with heat to deactivate pathogens. Poo, which has a high energy density, is a great binder for charcoal briquettes. I doubt that there will be tar problems in a gasifier.

Also, urine is a great nitrogen and phosphorus inoculant for biochar soil amendment. We are trying to create an ecological sanitation system that can be run as a business in villages of 500-1000 in rural areas. We think that we can deliver a very inexpensive service that creates fertilizer and cooking briquettes. This enterprise is two years old and we hope to have government approval later this year.

The carbonite is needed for a vehicle to transport the briquettes to a larger town where charcoal is the fuel of choice. Our customers still cook with dead sticks gathered from the national forest. The change over to charcoal cooking will take a while for our rural customers, but they really like our simple, odor-free, portable toilet.

Francois,

Thank you for the patent diagram of the carbonite press. The worm is very similar to the one in my sausage mill. I will try some modifications and give it another try.

Bruce, you will very quickly use the tools, because the charcoal is very abrasive, attached to a machine for spraying house plaster, has the advantage of resisting wear.

In the heading recumbent bike engine gas, you have the manufacture of carbonite in French, but the most to respect, is to grind the finest possible charcoal and the pitch that became solid in this cooling, and like that in the manufacturer, you will have a super homogeneous product with very little water that will require less neutral heat without oxygen, almost no drying, where a finish in the sun only.

Francois,

Thanks for the suggestions. The tip about “the finest possible charcoal” is most helpful. I suspect that my particle size is causing difficulties for extrusion.

This morning it occurred to me that carbonized cassava stems may be a good gasifier fuel. Already the right diameter.