Good morning Don.

How did you make your lid?

Do you have the opportunity to take a photo of it?

Here you go Jan.

The first picture is the top of the hopper opening with the greased silicone seal that I had before the greased stove rope seal.

This is the lid itself which is salvaged from an industrial 8 inch check valve with a neoprene seal pop off pressure release valve in the center.

Thanks Don.

Good solution with 2 fixing points on the lid.

Is the relief valve needed, doesn’t the lid do the same service?

The pop off valve goes before the lid raises because of the weight of the lid and the heavy spring.

Hello JanA,

On your open hopper picture your wood chunks look great. Irregular shapes making for gasses exchanging gaps in between.

They appear browned?

Is this from pre-torrifing them before putting into the gasifer hopper?

Or . . . browned from upper hopper tars dripping down onto them?

One thing that I’ve found helps is to put in the last wood fuel load timed to before the expected system shutting down.

So only a minor amount of above the air jet area of half-cooked, then dried wood remains.

Quicker next from cold starting up then with much less still not hot starting tars made then.

Regards

Steve Unruh

Hi Steve.

I am trying to come up with different big pieces, but have not succeeded yet. The last time I tried I could drive 2-3 kilometers, then out and stir in the wood, it had become a bridge.

I think the brown on the wood is tar, as I get so hot at the top when the wood hangs.

Jan, do you stop only because of high hopper temp or do you lose power as well? What about round limbwood? Does it bridge too?

Did you cut the protruding part of the firetube?

Hi Jan-O.

I lose the power too, there is a hole in the wood ca 2"-3" above the nozzles.

I have removed excess material from the tube.

I have no dry round wood yet.

I would too call the chunks in the open hopper pic perfectly sized. I’m amazed they bridge. I use exactly the same from time to time. Even in my little 8" gasifier they worked good. The only time I recall bridging is when using 100% slab chunks. The rebak didn’t cut them very well and they were stringy and held together like sausages. The hopper vacuum guage fluctuated some, but still I couldn’t tell much difference in power.

What about the screen you use as a funnel? Do you think it could interfere with the flow? I doubt it should matter much. Any funnel will end up with a sticky tary crust anyway.

I don’t know what to suggest apart from trying 100% roundies

Well in my experiences you are exceeding your current systems thermal capability.

This is hard to explain. Easy to demonstrate in real life.

The harder your gasifier system is worked by your vehicle the more internal thermal heat produced and the better it will be able to handle larger volumes of input fuel loads.

Ha! One of the real reasons Wayne Keith learned to be able to vehicle gasify so well and fast.

He first used a huge V-8 Ford in a heavy chassis. The gasifier was heavy demand loaded, producing lots and lots internal wood-cooking heat faster.

Then he for a while used retrofit engine belt driven air-blowers to cold start suck up his gasifier system to stable internal temperatures.

And so once learning well the actual wood gasifer system needs he was able to simplify. Run well without the super sucker blowers, on smaller V engines. One of the key operating techniques he shows is smaller wood-in adds. Acceptance of hopper fuel loads for 1-2 hours of operation. Then, stop. Leg stretch and refuel. He evolved past huge hopper with 8 hours of fuel loads.

This is thermal matching a system to it’s ability to handle the “wood-cooking”.

For now. Just use smaller dumped in loads of wood chunks to more closely match your current systems thermal ability to cook the wood and vaporize and convert the internal made wood volatiles.

Yeah. Yeah. Quite a bit benefit to having ultimate best-spec under 10% moisture by weight wood. Ha! You will always run out! That’s why to evolve a woodgas system able to fuel well with non-ideal moisture (20%, even 30%) wood in all of your year around situations. The Mother Earth News folks learned to do this on their systems.

Yeah. Yeah. You can follow debates about the better make-less-tars wood species. This is fantasy talk. Will not help to produce useable results. Fantasies never have to prove real results . . . just be entertaining.

Evolve your system, and especially your operating style, to be able to use ANY wood species local to you. THAT is the practical use way. Nail-soup. Stone-soup nourishes.

You will get there JanA.

I have confidence in you.

S.U.

Thanks for your trust Steve.

With your help I should make this work I think.

It is fun having a forum with so many helpful people.

Haha! Very entertaining but unfortunately false, Steve. You’re right most of the time, but not always.

Many local WW2 oldtimers prefered alder as gasifier fuel. Why? Less tar and soot.

Wayne Keith ran 90% pine for many years. He reported occasional early morning sticky throttles

and frequent intake cleanouts. He runs mostly oak now. Why? Less tar and soot.

Myself? I run a mix of species, but I try to avoid too much spruce and pine. Why? Tar and soot (+the poor structural properties of spruce char).

No fantasy talk.

I’m confident Jan will be able to DOW just fine on pure pine, if that’s all he got. But there’s no doubt pine is rich on tar.

Ha! Ha! I accept your criticism in the sprit you have offered it J.O.

Of course use the better wood species if you have a free choice.

Low ash. Low volatiles (tars). Actually this is a woods carbons to volatiles (H’s and O’s chains) ratio. And wood making the best formed char chunks.

But still I will say . . . . use what you got.

Open to all internet forums such as this you must acknowledge most reading and some talking, are not actually living Rural with access to wood choices. But Urban living. And they play gasification mind games just like Fantasy footballing games. . . .

“Want if we could get a combination of the Best . . . forward’ers, and the Best . . . mid-fielders, and the Best . . . goalie. What a team I would have! Unbeatable!”

Ha! Real Life in never a Football game. Real life is using what you do have and grunt, grinding it out for sustaining results. Work-teams. Push; Pull; or Get the Hell out of the Way.

Stunting!! Drizzling. Me . . .stunting, showing that engine gas can too be made in a straight piece of schedule 40 pipe. Yeah for mere minutes until the char bed consumes out and the flows choke with ash. Buck Rodgers systems (real 1980’s on knapkin drawn idealistc proposals) do not give travel miles and distances. Or hours, weeks, months of sustainable electrical generation.

My direct, even crude, Operator First ways do. How Wayne Keith was able to with only a half evolved system able to coast-to-coast the USA using roadside found woods.

How that Australian Evangelical preacher fellow was able to crisscross and round trip his BIG contry in his van with his not-perfect gasifier on roadsides found scrub woods.

How that French fellow with his woodbody converted Citroen ID/DS sedan was able to North Africa tour on found multi species scrub woods.

No home wood sheds full of the best selected species, pre-chunk made and dried fuel woods.

Needs must, man.

Regards

Steve unruh

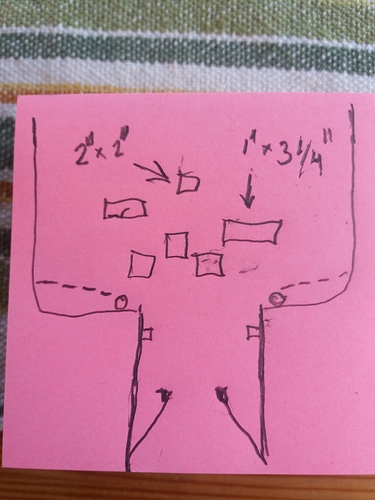

Jan I appologize for not getting into this discussion earlier. I am the kind of guy who is always trying to improve the gasifier until I finally have it where my truck won’t run. I have had successes which I will try to reflect in my comments. I run a '94 chev 1/2 T with a 4.3 l engine. I drove it to Argos 350 miles on wood one year. It is not important, but I made the gasifier out of a tire rim and 2 rear brake drums off vehicles that had disk brakes and a drum. You maybe can see each in this sketch.

I have had successes which I will try to reflect in my comments. I run a '94 chev 1/2 T with a 4.3 l engine. I drove it to Argos 350 miles on wood one year. It is not important, but I made the gasifier out of a tire rim and 2 rear brake drums off vehicles that had disk brakes and a drum. You maybe can see each in this sketch.

My basic dimensions are;

Nozzles;—5 at 1/2 inch dia.

Nozzle tip circle—9 in. dia.

Nozzle to restriction— 4 3/4 in.

Restriction—4 1/2 in.

Restriction to grate—4 in.

Air inlet— 2 in. dia.

Gas outlet— 3 in dia. all the way to the engine except;

The gas come out of the gasifier and into a cyclone, then into 4 in. schedule 40 pipe to go around the bed and cool. Then into the bottom of a 30 gal. plastic barrel filled 1/2 way with hay, and a 4 in. thick disk of closed cell foam. Out the top of the barrel to the engine

A couple more pic’s;

You can pick out the rim and one brake disk/drum and grate made of 3/8 rebar.

Placed a cone/ring over the nozzles to force the wood past the nozzle tips

Now for yours. I think you cut the fire tube off that was protruding above the nozzles into the wood hopper. Good

Now I would like to see a steeper sloped (60*) cone in the hopper and may something like this so the wood will slide into the fire tube.

Then possibly take the part you cut off the fire tube at the top and weld it onto the BOTTOM of the fire tube, making the fire tube extend about 4 in. below the restriction. Now make a grate and fasten to about the new bottom of the fire tube— fasten it solid or loosely with chains or on a shaker device.

All this to help and force the wood to flow in front of the nozzles. The grate should keep the center of the wood reservoir from falling through leaving a hollow center for the heat to go up into your hopper.

Then like everyone is saying move you gas out let up. I also think you are losing velocity by going from about 2 in. in to 3 in out of the cyclone. What ever you have at the bottom of the cone is ok. I didn’t see, but are you going from the cyclone to the cooling rails and then to barrel with what ever you are using now?

Good luck TomC

PS. I’m surprise that Kristijan hasn’t suggested it to you but if you have moisture problems, try adding a mix of wood and charcoal.

Thanks for the tips Tom C.

I have almost the same dimensions as you. The nozzles are 5 and 10 mm.

The restriction is currently 4 ".

The tube was shortened to just above the nozzles.

Cone 60 degrees inserted.

New bottom with higher positioned gas outlet.

Grate inserted with ash lid.

73mm exhaust gas and 48 mm inlet for air.

Thin with half hay and half sheep wool.

The foam you use is the same as the bed base?

Yes Jan. The foam is from a bed mattress. I should think with those dimensions, you should be good to go. Getting the fire tube cut down and the grate should keep the wood from falling in from the center of the hopper. That allowed the heat to go up to your thermometer. Does you plumbing go from gasifier to cyclone to cooling pipes, to hay filter? Some where in reading back, I thought it was said you went from cyclone to HAY FILTER and then to cooling rails.

Performance; Don’t expect speeds that the Dodges with the WK gasifier are getting. I have no speedo so I guessed at my speed. On the Interstate, cars passed me at times, but I was never in their way even going through down town Chicago. So I always felt I was running 50+ mph. One of my rebuilds I made a WK fire tube and my truck ran much faster, but I had a problem that other WK builders have had. The metal around the nozzles gets fatigued from heat

Anyway good luck TomC

Jan, you really put some effort into your build since last time we had a detailed report.

Only a minor suggestion while you’re still warmed up: The horisontal part of your hopper drain will work for a short while in warm weather. After a while and/or cold temps it will plug with tar. I cut off my horisontal part. I saved only the prefab weld on the elbow as a flange for the hose, since the drain unfortunately is conical. No plugging ever since.

I wish you many happy miles. I wouldn’t mind a visit as soon as the S10 feels like stretching its legs

Hi Tom.

The pipes go from the cyclone to the radiator then to the hay filtered, I had to change when I removed the metal grid.

JO, thanks for the tip, have to make another tank for the water, so I can remove a bit.

Yes, if it works it would be fun to come up to you, but now the wood has to dry before I drive.

Really nice weather forcasted. Chunks should be dry next weekend