Oh, you’re trying to excuse me, but I’ve got so many good suggestions so I do not know where to start.

I started by getting more firewood, I have to have it, even if the pieces are a little big.

Then I’m in the woods and chopping, when it’s light in the day, so the time is not really enough.

Have a forwarder that comes in the first place, who does not want to work, has rust in the tank and something electricity wrong, pooh.

Tips and tricks:

A neighbour of mine used to say he always started full speed in the morning and kept accelerating all day long ![]()

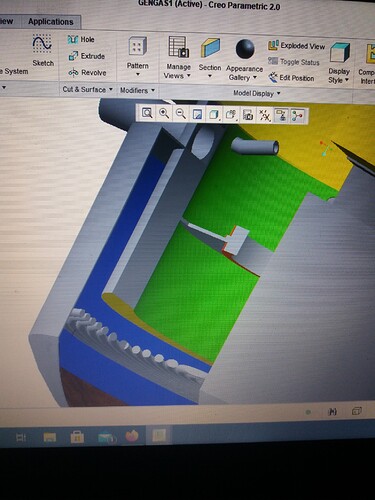

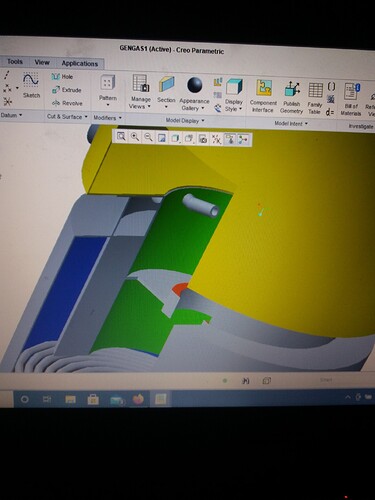

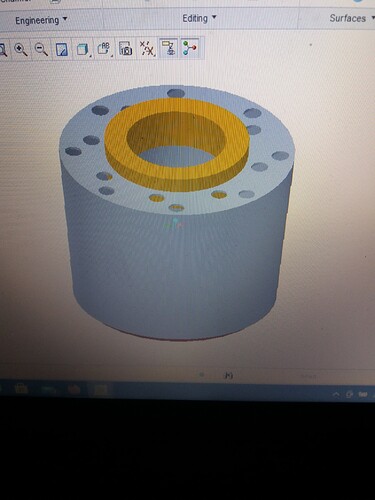

I had to borrow a drawing program, and drew for a few hours.

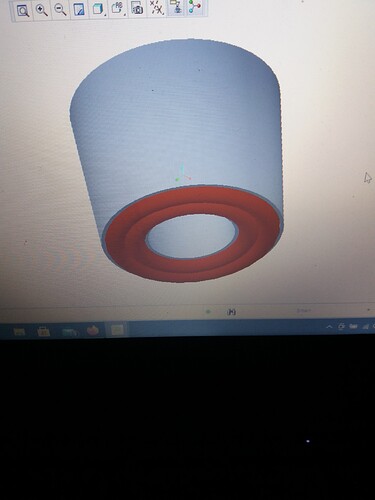

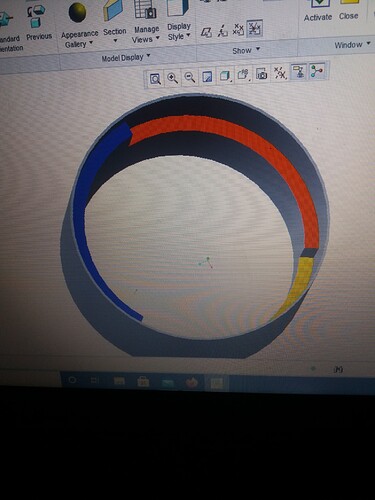

This is roughly what the current unit looks like, except that the fire tube is only like the inside edge of the nozzles in diameter.

One wonder I have is if it is better for the fire pipe to go alone against the grate, or if it should be a gap.

Today I have another pipe that goes on the outside of the fire pipe and is against the grate, I think the car runs better after this.

Jan; Very nice job on the drawing. I had drafting in high school and in college ( using pencil and pen). I down loaded a program. The 1st lesson was to draw a chair. After a good effort, I decided ,I failed. When visiting us, my grand daughter sat down and drew the chair. She had never had ‘‘drafting’’ in school.

About the grate— I doubt if the placement, within reason, of the grate will make a ‘‘noticible’’ difference in performance. Maybe a little difference in the amount and size of the ash. TomC

What I’m thinking about is how far I should have between the choke and the grate, that should be where most of the good gas is formed, right?

It depends on what heat it will be, but is there any harm in it being a long distance?

It says in my old books that you should not have more than 10cm (4 ") (frozen equilibrium) but I doubt it after my attempt with the outer tube.

Jan; Take what I say with a grain of salt, but my thinking goes like this: ‘‘reduction’’ is a cooling process. You don’t want the distance the gas travels so long that the char will cool below the temperature required for a reaction. The cooled char if it hasn’t reached a size that will fall through the grate, will plug the grate. The char has to stay above the reaction temp all the way to the ash pit. The object of an inverted ‘‘V’’ reduction zone is, it holds char/ash on the back side of the ‘‘V’’ which insulates the reduction zone to hold the heat longer.

I ‘‘think’’ that if the grate is tight against the firetube, the gases have to go straight down through the char and grate. If the grate hangs below the firetube, the path of least resistance is for the gas to escape between the grate and firetube. This can create a pyramid ofcold char on the grate. Again plugging the grate. Hope this helps. TomC

Jan, my WAG is the better performance is because of less char is slipped and a somewhat more insulated reduction with your additional tube.

…between restriction and grate?

Only harm I can see is risk of plugging and unnecessary restrictivness.

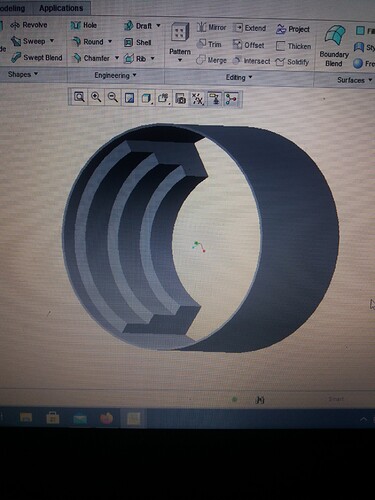

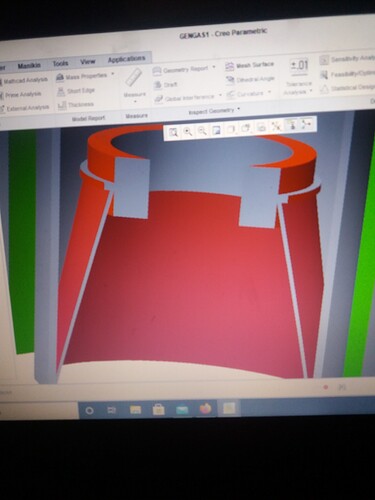

Ok, so if I did this, double-jacketed fire pipe with insulation in between and upward directed nozzle.

Morning Jan; Not a fan of this latest drawing. This looks to me like you have an opening going from the outside directly into the oxidation zone. I see the turned-up tuyere. It will be interesting to see how it works. We do have a couple of builders who point the nozzles directly into the restriction.

OK About the insulation of the reduction zone. What I had in mind, if you are following my suggestion, I meant to insulate the wall of the reduction tube, directly. As you can see with the inverted ‘‘V’’ reduction zone… I have built one using one cylinder inside of another. Had holes in the restriction plate that allows the ash/char to fall through and fill the space between the cylinders, insulating the wall of the reduction zone. I forgpt to say, using a ring, I sealed the space between the two rings at the bottom. Then a layer of insulation like you show only on the outside of the ash-pit tank. (trying to write this at the same time I’m watching GunSmoke) . TomC

Thanks for the suggestions Tom C,

I think it looks like that because of the recess I made so you could see how I thought,

There’s something like this you did for the insulation, did you think it made any difference?

I think if I were to build another Imbert style gasifier I would probably use my original Rabbit design. I just prefilled the void between the reduction walls with white ash. It preserved the heat very good. Very little hesitation sympthomes, even after long term idling.

Hello, J-O!

I cannot pinpoint in what circumstance I have used the word, so Any answere could be wrong…

Max

Excuse me Max, I was the one who asked if this is what you thought, Jan.

Hi, Jan!

9.12.2020

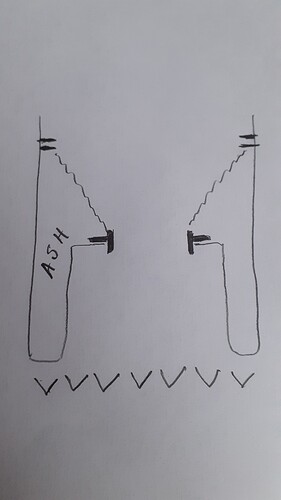

Untested idea for hanging:

Make a “staircase” 1/3 perphery wide.

Bend the steps horizontally along the silo wall.

Height from step to step: one hand width. (~4")

Step material: 0,5 --1 X 3" horizontally flat.

The “poles” 2X2".

The principal of action: The ladder will hold up a part of the clogging “piston”, forcing it to continuosly brake into peaces when it attempts to avalange as a whole peace.

Max

" I did a cone under"

Mee too, on the Mazda gasifier.

But I THINK mine is a bit too wide and short.

It seems the narrower but taller Rabbit reduction had better heat economy (it was about as tall as it was wide)

High, Jan!

27.12.2020

Now, when re-reading the whole story, I am recalling the suggestion:

Those 120 degree sector steps were not supposed to be “piled up” in one sector all together under one an other, but spread out like a screw, each in its own 120 degree sector, like a bold screwed staircase, one step per 120 degrees of rotation.

Make a paper model, or a new computer drawing. I hope this has any sense in it…

Preserve the inner radius decrease for each step, so the end result looks like a “screwed” cone.

Max

Jan,

Haha, I’m so sorry. Reading back it seems I interfered with my own jabbering in the middle of your discussion with Max - creating confusion  Also, different subject

Also, different subject

Thank you JO for the drawing. That represents what I was saying about putting one cylinder inside of another, and filling the space between the two with char/ash.

Jan; I have done so many changes to my gasiphier that I don’t remember them all. With each change, I was looking for that ONE that would make it run like on gasoline. It hasn’t happened and I doubt it ever will. The only thing I have learned is, we need to create and maintain as much heat as we can in the reaction zone. That includes engine heat added to the air going into reduction zone and conserving all the heat you can in this zone. Probably some of the changes I made may have made slight improvements Like JO says, insulation of the reduction zone helps in idle or starting off from a stop. I was looking for another 10 mph or something at top speed. Don’t let you expectation confuse you as to if something works or not. Give each change enough road time to see if maybe you haven’t gained some improvement you hadn’t expected. TomC