Hi to all of you experienced builders, I have a smal farm here in the midle of Norway.

The plan is to implement a CHP system using wood chips from my forest and the surrounding fields.

As for the timeframe I do not have anything set in stone but I give my self a year to have a smal container CHP, and then another year for a inhouse automated CHP room in the barn, to heat workshop, other rooms in the barn, chicken coop, house with hot water tank and as a bonus if possible heat and CO2 for the greenhouse,

Im going to update this frontpage with the best solutions at current date. (bare in mind my english skils and spelling)

Now for the plans and ideas. (all input and dicussions are welcomed)

Housing for the first CHP is a 10by10 foot

Container pod, a little insulated (10cm glasswool) plywood roof and walls. (might get fireproofed later)

The gasification unit and powerunit

I like the GEKTOTTI design, the way the gas flow on the outside of the inner chamber to preheat injected air sound like a good idea to me, Im not going to mess around with waterinjection until i fully understand how that work. Everything is going to be insulated from the surrounding environment eventually, not only to prevent overheating in the small pod but also to keep the energy where its intended to be.

Exhaust gases from the gasifier is going to preheat and dry the woodchips until desired temperature for combustion (not shure what the desired temperature is).

Storage for weekly (or as long as possible ) buffer of woodchips is going to be on top of the pod, its easy for me to load it there in the begining with the frontloader of the Valmet tractor and the big snowshowel.

This is what Ill use as a feed screw on the roof.

Eventualy I hope to have a double perforated floor on the top of the pod to dry the biomas with left over heat and forced air.

The gasifier

Hopper material

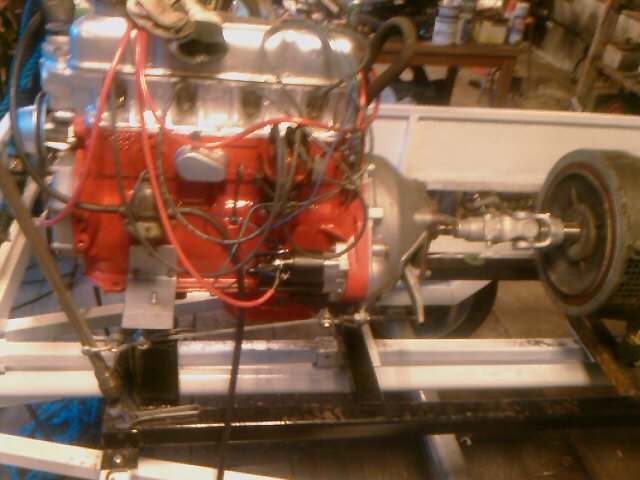

Motor and generator

The motors im going to use in the beginning are B20 Volvo engines, the reason for this is simply that they are simple motors, relatively low rpm, not picky on the fuel, easy to adjust timing and I already have two of them here on the farm. Also very cheap parts. https://en.wikipedia.org/wiki/Volvo_B18_engine

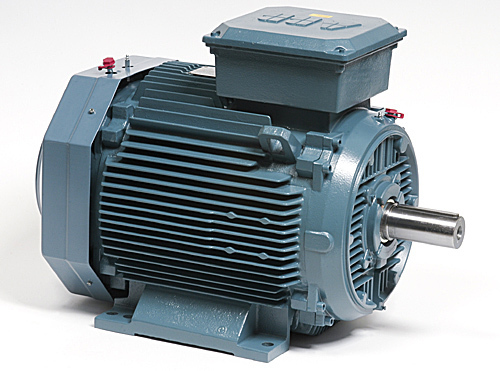

As for the generator

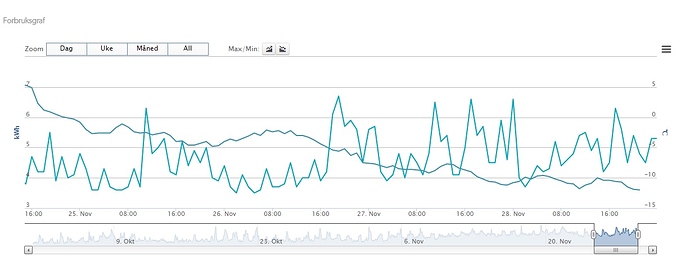

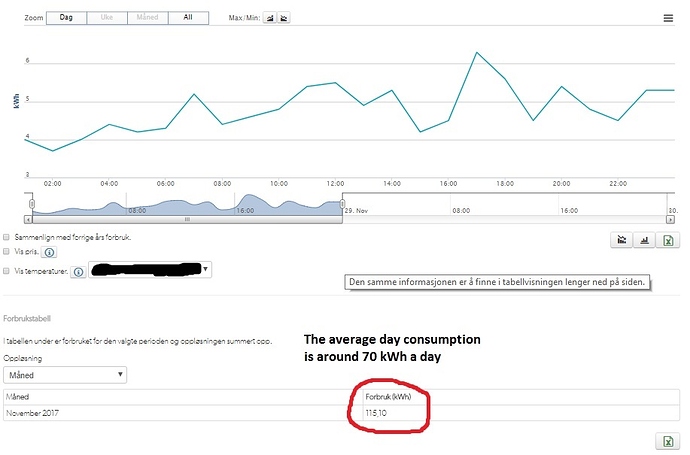

I think asyncronus motor is the easy way to go for grid tie, start the B20, get the RPM to the rated rpms of the generator, flip the braker to synk the grid and motor and then increase the RPMs about 10 RPM over rated of the generator (amp supervision to decide when you have reached rated amps)

I have not decided yet on the type of electronic supervision, it might be a hybrid solution of arduino, raspberry and Siemens PLC.

Heat storage

Idealy all of the heat generated by the B20 motor and gasification is to be used in one way or another.

All cooling fluids of the B20 motor is going to be heat exchanged against a 5000L buffertank, maximum 95 deg. C

High manifold temperatures in the botom of the tank where the water is coldest, left over eccess heat to be used to dry the biomas, the now cooler exhaust gases to be sent in the greenhouse for CO2 and heat. (filtered and not to be used when people are inside)

So this is the plan, all input and ideas are welcomed.

Ill update with pictures and video as I go.

Roger

![gektotti-v4-2-800[1]](/uploads/default/original/3X/a/a/aaa6b52c5742b0a884af2bb84111678888e2c832.jpg)