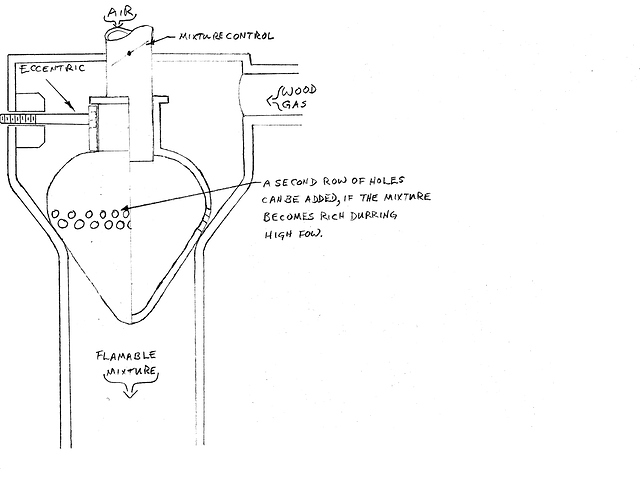

One more thing I would like to warn you, Rindert, the holes on the moving piston must be drilled from behind the venturi, therefore, in the lower pressure range

Hi Til!

The cross-section of the gap opening between the venturi and the piston (gas) must be equal to the cross-section of the holes or the slots in the inner air pipe, and the total cross-section must be at least as large as in the existing carburetor.

Hi Tone,

thanks for the fast answer!

Together with your post no. 27 I can now understand “the magic” behind your mixer.

Thanks again for sharing it with us!

Til

As l understand the Venturi effect is what makes this thing mix a solid ratio, just like a propper petrol carbourator. But we are lucky, even a less thain perfect woodgas mix will still run a engine flawless, wich is not the case with petrol.

Only thing that can throw it out of range is gas quality. And air leaks! Those must be eliminated at any cost, like with a vacuum automixer.

Hi, Rindert!

28.4.2020

You forget that after this flow dependent body comes (at least in the original version)

a manual (footpedal) manouvered regular flap!

That eliminates any wild running !

In my humble opinion the original “flow-following” and reading regulator body is the principally right and most smooth way to “read” (not enforce!) and “administer” the second gas dispencing.

The two arriwing gases may have different and varying pressures too… all to be mastered some way…

Max

Hi, Till!

28.4.2020

Fundamental principals tend to jump up time after time!

For physically “equal” gases:

Same pressuredrop over equal passage-areas leads to equal flows…

If all constructors should start thinking from the “bottom” of the available facts,

the constructive aims would have a better chance to reach some goals…

Time after time the idea-enthusiasm overruns physical fundamentals.

Yes, you may be right. Your idea uses many pressure effects including Bernoulli’s principle. And it WORKS. I have great respect.

However, I think my idea will work too.  I am making a charcoal gasifier so I can test my idea.

I am making a charcoal gasifier so I can test my idea.

Rindert

Tone,

You understand fluid mechanics, so I think you will like to read about why Mako sharks can go more than 100 km/hr.

Rindert

Good job pursuing this Tone.

I once saw pictured and illustrated a Canadian large electical generating woodgas engine mixer using a center pipe movable double ended tapered: “Almond”. It too metered out on the lower flow side of the movable restrictor.

Article was low on details due to pending patents.

Ha! I tried but could never get a copy to work.

You have my hats off in respect.

Regards Steve Unruh

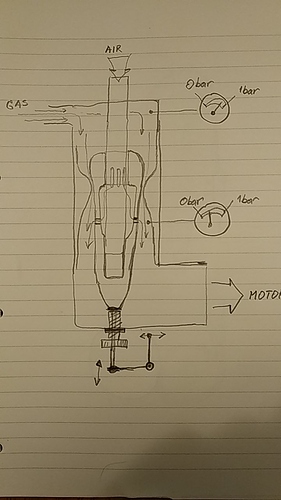

I am thinking more about this gas carburetor. I was too excited before because I had a new idea. But I had not completed my thinking. Here is a better sketch.

Rindert

Thinking about the problem and respecting the physical and mathematical laws always bring some solutions, but if they are the right ones, practice shows. I wish you every success.

ah now we are getting some place a eccentric to open the bobber as yous called it that will work better those carbs that you showed for gas are used on many of the older gas carbs they were worked by vacum of the engine. volvo used them until they went fuel injection they were the best carbs made i use one on my tractor i have used it for 20 some years now my bike uses the same thing the trottle valve opens allowing the vacum come on the engine side of the ventura the vacum applys suction on top of the diaphram that will lift the ventura as the centre is called. with the gas carbs there is a needle valve that moves up or down with the ventura to control the fuel opening. very rare you ever get the wrong mixture as the vacum moves the ventura up or down to keep the mixture right at all times. it is only hooked to the throttle by a vacum port. that might be a way to hook the bobber up as well so you will not need a mechanical conection. then just put a trottle vave an the engine side . your carb mixture could then be engine vacum modgelated

That sounds really cool. Do you think a DIYer can make all the parts for that? I KNOW how to make an eccentric, and using a lathe and plastic pipe fittings I can make all the other parts too. ChrisS figured out how to make a diaphragm pressure regulator ( gasp). Do you know where I can find a diagram or something like that for this vacuum modulated gas carburetor? Thanks

Rindert

first of all the diaphragm is the hardest part to make it is a cloth covered with neaprean with a tin ring covering it i have never made one i always buy them i wouldnt know were to start but a craftman could design a good one. check the internet on floating ventura carburaters. it will tell you how they work. the diagram would be hooked onto the bobber at the top and the upper part would need a way to hold vacum etc. they are simple to work and fix. lately my designing skills are not much good sorry. I can see it in my mind it is simple but can explane it i have been having that problem a lot in the last couple of years. . I think the heart valve is taking away that part of my mind can seem to do other designing projects here either.

Hi, Rindert!

1.5.2020

Look in gasmixer projects!

Twin throat twin flap dispensing mixer 50/50%

Chris made a series of articles as he built one to his truck.

Max

Hi, Larry!

A membrane, big enough, sensitive enough: Plastic sheet between two aluminium (circular) plates, incapsulated between two household flat pots.

“Pistonrod” out through (airtight) on the airside of the pot.

Small leakages drown in good sample tubes.

The piston rod regulates a “third” flap situated in the air-line,

a bit before the dispencing airflap.

The sample points are clearly (and mandatorily) defined.

Read Chris’ articles, full of pitures…

Max

Arrrrg! You make me want to do it wrong with such language. Who are you to mandate anything? I would follow the dictates of nature and her Creator.

Anyhoo, I’ve been thinking I could maybe make a gate valve instead of a butterfly. The ‘piston rod’ would go thru a brass sleeve and be connected directly a thin piece of aluminum drink can (the gate).

Rindert

I like the American proverb. “Many ways to skin a cat”. Only mandatory thing to do in life is to dye in the end. Rest is up to us.

Max, with all respect, l find doube twin flaps a unnessessery strugle. I tryed many automixer systems, one with twin flaps, the rest without. They worked just the same.

If you look at it, most of the time we drive at WOT or near it. In that case the twin flaps are open all the way and its no difference between 2 flaps and just 2 identical paralell legs.

But in either way, the negative things regarding a vacuum automixer still stay…

Rindert,

That is a REALLY cool paper you referenced. All of us techno-geeks should read that. Thanks!!  While you are at it, read about the Kline-Fogleman airfoil. Maybe that is how those new hypersonic aircraft work. Tin foil hat alert.

While you are at it, read about the Kline-Fogleman airfoil. Maybe that is how those new hypersonic aircraft work. Tin foil hat alert.

Hi, Kristijan!

1.5.2020

It sounds like you either drive with constant pedal in bottom, or have some automatic gearbox, that holds down the motor while shifting…

Furthermore, the twin throat twin flaps are ganged and move in syncrone. Ganged together and moved by the gaspedal.

The third flap in the arriving airline is manouvered by the bellow membrane, and has as only task to set the arriving airpressure equal to the arriving gasline pressure via sampling tubes from each arriving mainline, just ahead of the twin throat mixer flaps.

A vehicle with manual gearbox needs manual “footwork” and light gasfoot in towntraffic…

Max