some time we make things to hard. the rod from the diaphram to the fuel control or bobber as you call it does not need to go through anything as the vacum is on the top of the diaphram not the bottom the bottom is exposed to incoming air at normal air pressure.and yes there are many ways to skin a cat but you may have to ask some one else as i dont eat cats. ha ha ha: also there is not many negative thing about vacum mixures except los of vacum they resopnd instantly as any on who has used them will tell. i have never heard of twin flaps but we can all learn somthing new i guess. the only thing hooked to the throttle would be the throttle valve which every carb needs it doesnt matter if it is a butterfly valve or a ball valve as long as it controls the amount of mixture going to the motor. if you dont use a throttle valve the motor will run so fast it will blow apart as soon as the load is dropped

I have learned to drive with WOT practicaly all the time. I drive with the gearbox, let the rpm dictate how much the gasifier is pulled, not the gas pedal. At least that was the case on the MB. We will see how Škoda will do.

Ofcorse l have a throtle body  but as any woodgaser will tell there is not much difference in power if you use 1/4 throtle or wot, because of the drag of the gasifier. So instead of holding it at 1/4 l hold it wot and shift up if l want to go slower. Hard to describe.

but as any woodgaser will tell there is not much difference in power if you use 1/4 throtle or wot, because of the drag of the gasifier. So instead of holding it at 1/4 l hold it wot and shift up if l want to go slower. Hard to describe.

No dubt a vacuum automixer does what it is ment to do. Problem with it is sometime that is not desireable… per instant, there is no way to richen the gas at startup or whatever. Leaks are a poison. Hybriding is compromised…

A carb or fuel injection doesent always make a 14.7:1 mix. At acceleration, deceleration, hard pull… the mixture changes. So shuld a propper automixer do with woodgas.

What l like about Tones automixer is its “programable”. The gas slots culd be made so that thay vary between different plunger positions. Make gas richer at low or high demand, depanding on wahat shows to work best. Not to mention it can do any gas/air mix you want, making it usefull for other gases too. Heck, there is even a big difference in gas/air mix in the wood gas family! Wood, EGR tempered chargas, water injected chargas have different a/f ratios! Anyone that played with a charcoal gasifier will tell that if you run a char gasifier on pure air and start dripping in water, first thing to do next is open the air valve more!

Haha!

Kristijan, I couldn’t help it but your driving style reminded me of an old fart…hm, elderly gentleman nearby. He was hard of hearing and he always used to drive WOT too. His rpm was constantly above 5,000 and he adjusted the speed with the clutch in a cloud of smelly smoke

Sorry

Hi, Kristijan!

2.5.2020

Ha! There is nothing new under the sun! (almost…)

Before you deem out the two-throat gasmixer,

have a new go with Chris’ documentations!

There is a well described version which allows stepless

00 – 100 – 00 % gas/air ratios adjustment during drive!

No pre-programming or locking.

Max

Haha thats exactly how my grandfather used to drive  we joked that his Fiat Panda had a diamond clutch, it never broke!

we joked that his Fiat Panda had a diamond clutch, it never broke!

In adition, my grandfather “had” only 2 gears - 2nd and third

Max, l read trugh Chriss exelent report probably 10 times and l remember his lego twin flap model. However it is important to know that model can never mix a linear ratio mixture! A butterfly flap does not work that way! Its opening vs flow is not linear but has a wery steep curve on a opening vs flow graph!

Hi, Kristijan!

Again, generally wellknown facts. There has not been any demand for linear ratio adjustments on either side of 50/50!

Then, with the ratio adjusting model (Chris):

The goal was to be able to do adjustments according to momentary needs, from the dash.

Mostly near around an eaven mix, if set 50/50

And temporary shutting down woodgas 00/100. Fast gasoline blast.

This far the ratio adjuster modelled by Chris.

========================================

The fundamental mixer 50/50 % (constant ratio):

(Without ratio regulating disk)

I dislike to repeat, but:

“Equal pressure-drops over equal openings result in

equal flows.”

That is the situation in both throats. Because of identical ganged flaps.

And equalized arriving pressures. (to these throats.)

By the membrane.

Max

I’ve been thinking of raising a Tin Foil Hat Brigade. Would you like to enlist?

Rindert

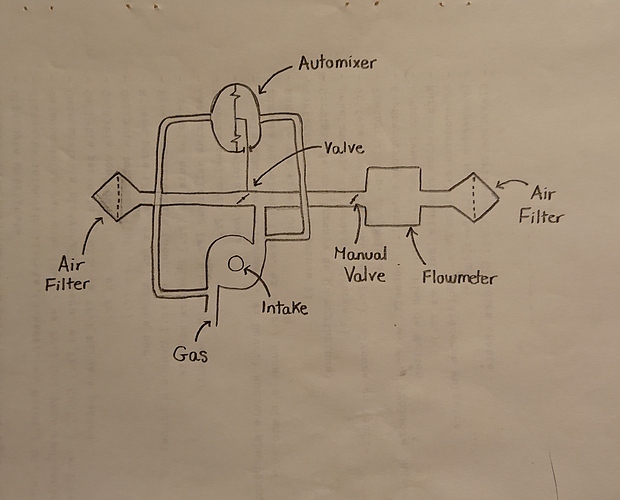

I try to adjust this design on my truck. I hope to be able to hybridize chargas / gas in this way. am i wrong?

if the consumption is 100% chargas, the manual valve is closed (50/50 mixing thanks to the automixer)

If gasoline assistance is required, partial opening of the manual valve and adjustment of the fuel pump (pwm) according to the AFR)

if i am wrong, i would appreciate your feedback to correct me.

this construction of gasifier requires a lot of time and at this time of the year I am very busy. I try to avoid wasting time as much as possible

Thierry

Thirry, no, the sech will not work. As soon as you start to open the manual valve the automixer will want to correct it back to 50:50!

You need to move the hybriding air valve to the gas side!

Hi, Thierry and Kristijan!

2.5.2020

Eaven this, by Kristijan proposed version does not completely “bypass” the air/gas automixing!

Following Kristijans proposal, the incomming gasoline/airmix will be further diluted if “infused” into the “gasleg” of the automixer.

The “clearcut” solution is to go “below” whole the gasmixer, directly to the motor’s intake manifold and keep the gasmixer flaps (gas and air) closed (100%).

But this asks also that the air/gasoline route shall have no “idle” leak during woodgas driving.

Max

Hi, Thierry!

3.5.2020

With a clear risk of being “picky” I have a question about your drawing.

A two-throat air-gas mixer for 50/50 mixing needs two equal long (identical) tubes with equal-geometry flaps, ganged together, so that they operate in synchrony and meter equal flows.

To get equal flows, you need pressure sampling ahead of both flaps by a membrane between 2 “cups”.

The membrane adjusts a 3:d flap in the airline so the arriving air-pressure levels with the arriving gas pressure.

OK

The main criticism is, that the sampling points are not near ahead of the points of “flapping”= regulation, but instead very near the point where they flow together! How to “identify” the differences in the two routes? when they are almost flown together?

That gives an “unspecific” regulation quality.

Picky as picky!

The gasoline/air delivery is best to deliver separately between the described (char)gas/air system and the motors intake manifold.

Max

Hi Kristijan

here is an explanation of how i understand things :

1 in the situation where the engine is 100% chargas powered. It is the automixer that adjusts the right air / gas mixture.( manual valve closed )

2 in the hybrid mixture situation (petrol / chargas) the mixture is adjusted manually

if the manual valve is partially open (to hybridize the mixture). The automixer will close the left air line (the pressure of the air line being higher than the pressure of the gas line ) and the air then arrives through the flowmeter . The injectors will be able to +/- enrich the mixture (thanks to the adjustment of the PWM of the pump)

Where am I wrong?

Thierry

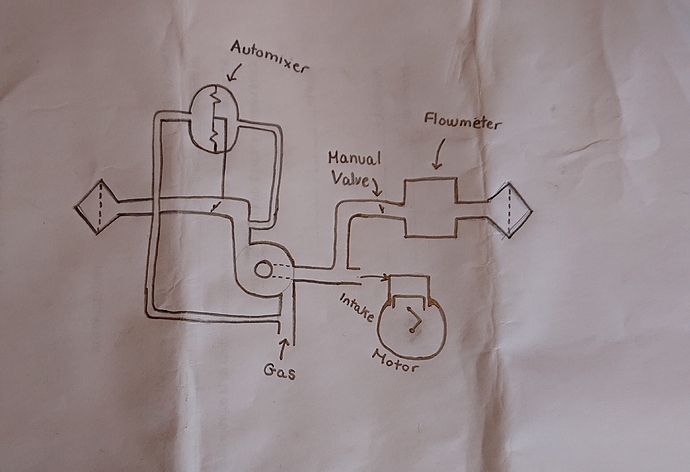

Max, thank you for your reply.

I think I know the conditions for the proper functioning of the automixer but the space I have in the engine compartment is reduced and I can not install double flaps

is this what you suggest to me?

Hi, Thierry!

4.5.2020

The only improvement so far is the gasoline "gas"route in “Direct mode”!

It seems, that you are swirl-mixing together gas and air. Good.

But your pressure sampling has no sense!

You have one flap for air OK.

Add another IDENTICAL flap at the gas inflow! (same geometry)

Gang these two flaps together, with identical closing angles (and full opening angles).

Connect the ganged flaps to gas pedal.

Membrane diameter over 200 mm !! preferable ~300mm.

The membrane sampling tubes just before (in flow direction) these ganged flaps.

Then add an extra flap before the sampling-tube (in flow-direction) in the airline.

Let the membrane piston-rod now control this "3"flap!

Synchronization:

When the gas-side pulls the membrane, close the air-flap.

When the air-side pulls the membrane, open the air-flap.

If you do a neat work, I hope you get a neat functionality…

Max

Hello together,

I spent some time thinking over the “classic” twin-flap-automixer (see here: Vacuum Automixer project) and Tone’s automixer. Let me write down the pros and cons of both, which came to my mind.

Tone’s automixer:

Pros: Less parts, gas-air-relation “programmable”, insensitive to vaccuum fluctuations in the gas-pipe, good mixture from start, good gas-air-mixing due to venturi-effect, blocks off gas and air pipe when engine is stopped (valve seated in the venturi restriction)

Cons: probably higher flow resistance at WOT, prone to gum up with poor filtrated woodgas, no pressure compensation in the air-pipe (dirty air filter).

Classic twin flap automixer:

Pros: Lower flow resistance at WOT, compensates pressure variations of both air and gas pipe

Cons: More moving parts, needs some turbulence after the flaps for good mixing of gas and air, fixed 50/50 mixture.

I thought about "fine-tuning"of the mixture. This may be sometimes needed due to fluctuations in gas quality.

My idea, if don’t want to move too far away from 50/50 with the classic automixer: With a tiny three-way-valve you could lower the vacuum on one side of the membrane for a leaner or the other side to get a richer mixture. (Sketch from Max: Vacuum Automixer project - #145 by gasman)

For Tone’s mixer, it could be possible to adjust the basic mixture on the rich side and then blend some air in the woodgas pipe before the mixer to make it leaner.

Advantage: With the automixer you get a quite good mixture to start with and then you can do some fine-tuning with the air valve while running to find the sweet spot.

Hi,Til!

04.05.2020

I think we both this time left out the disk the gas-pedal first activates, as it has been described so often!

And modeled by Chris.

This disk covering "opposite slide-track settings for the gas- and air flap connecting rods 0 – 100% for each in opposing phase…

This, because of cram places in this case. But always available…

Max

Hi Til

this idea seems very advantageous to me to correct the fluctuations in the quality of gas. a simple micro solenoid valve on a bypass pipe between the two chambers of the automixer could easily be operated from inside the vehicle (possibly , automated / lambda / arduino probe … ![]() I dream)

I dream)

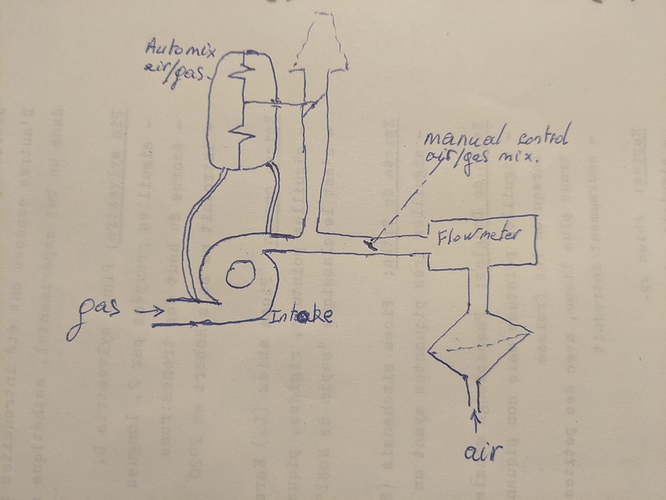

Max

does this diagram speak to you most?

it is similar to the previous two

the mechanism of my automixer is a little different from your

https://youtu.be/dj2R-8H5J4k

Hi, Thierry!

4.5.2020

NO! There is nothing regulating or controlling the gas-side!

No control without control over BOTH “legs” and their ratio.

A complete control does not get better by cutting off either member of flow!

And sampling should NOT be taken where the both flows are almost flowing together!

Where is the “individual” pressure then?

And that flow-meter route is placed completely random without controlling even the whole airstream!

Where is the logic?

Max

Hi, Thierry!

4.5.2020

Difficult to see details in your video,

but:

It seem you are blowing and sucking from one side of the membrane-pot ,

but the other side seems to have a lot of FREE HOLES + one bigger!

That gives no possibility to compare two different pressures when

neither of them are = the atmosphere!

Following instructions usually gives predicted results!

Doing otherwise gives different “results”.

Max

Perhaps your dream is not so far away. I would use an Idle Air Control Valve (IAC), on most vehicles. The one on my '91 Ford 2.3L uses 1.2A, 12V. A low cost PWM power supply can be had from ebay. this would be controllable from the dash or via lambda, arduino & etc…

Rindert

https://www.ebay.com/itm/5A-3-35V-12V-24V-PWM-DC-Motor-Speed-Controller-Adjustable-Switch-LED-Fan-Dimmer/133330551163?hash=item1f0b1ec17b:g:bNsAAOSwo-5eQkiF