Any advice how I can use this meterial because cze this is what we get from the chipper. Sustainable wood haaaaaaa

There appears to be far too much fine material amongst the wood chips for proper air flow. Generally if such material is intended for gasification the fine material is screened out and discarded.

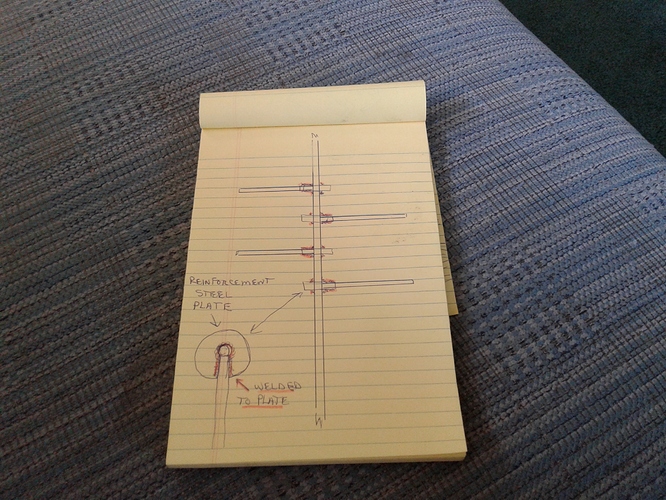

Hi Faazil, if your poking device is going to turn in the hopper area then maybe the rods are going to need some reinforcements. Wood chips are dence when piled up in a vessel.

Here is a drawing of what I am talking about.

If these rods get into the hot zone of 2000*f they could melt. The bridging often occurres above the reaction zone.

The rods Do Not need to be moving all the time, just if bridging occurs.

Bob

What shall i do because i have no other option. Any recommendations

Hi bobmac, i had an old stainless steel 316 Rod so i used it. I will take ur advice and modify my poking rod. I thought to keep it working always therefore i can maintaim a good level in the gassifer.

Is my idea good or shall i just use it when bridging occurs.

Set up some sort of rotary screening trommel, as it looks like this is the fuel you will be working with long term.

For the sake of testing, it will be best to set up a sort of manual shaking screen, so you can prove what performance you can get from the sorted wood chips before going further.

This type of gasifier is like others have said, very sensitive in It’s operation, everything has to be just right. The problem is everything in gasification is changing all the time when in operation.

I have a Question , do you own this gasifier set up, or is it a co-op ownership group of people that have invested in it.

Bob

Hi Faazil,

Take a look at this German guy’s Youtube channel.

Several different gasifiers running your kind of fuel. Some running open top, but with nozzles. Also a drizzler without nozzles. It’s a lot of junk put together, but it works. Might give you some ideas.

He’s got plenty of inpirational videos. Two of them here.

A nearby wood mill bought a used woodgas system a couple of years back. Their idea was good and noble, take their waste wood/bark, chip and gasify. Power a generator and produce electric power for their own needs and pipe the exess heat generated to the nearby village. Long story short, their experiance was similar to yours. This investment allmost destroyed the entire company becouse all they ever got back from it was tar and dirthy workers fixing the mess longer thain the system operated. And, what is perhaps the worst, woodgas got advertised as a dirthy, unreliable and useless energent.

No need to scare you, one thing is for sure. You came to the right place for help.

The shape/size of the fuel is not at all ideal but l have no dubt it can be made to work. But like many sayd before, moisture is your problem. What l wuld do in your place is take the exess heat from the engine and exhaust and use it to dry the wood chips. This culd be eaven done if you modify the silo (before the elevaror), just blow hot air on the bottom, maybee mwke the silo higher so that the top chips has time to dry till it comes to the bottom. This way you basicly eliminate any extra operation procedure.

This alone will help a lot. Second l wuld focus on the gasifier. Its basicly a FEMA as l understand. Its not hard to make a lmbert out of a FEMA, just add nozzles and if neaded, a restriction. Ofcorse a top lid is then neaded, but in my opinion it doesent need to be absolutely air tight. The objective here is not to strictly follow lmbert principles and geometrics, you just want the burn zone to stay where you want. I guess if you deliver 50% of air trugh the nozzles the problem shuld be solved.

My 2 c

Hello Faazil,

Abandon the rotary stiring device. The material drag of the chips mass will stall it out or break it up.

Go back to the old stationary gas plant days and use heavy vertical dropping rods. Rotary electric moter cam lifted. Then cam-notched, dropped.

Go to the IISc.cgpl site and see from their later systems that all of theses do have water-ring sealed cone top-hats. You must control the upper system in allowed air. Open. Then batch feed. Drop back down air sealed.

Others have valid commented on other problems you will have.

Best Advice from me.

Accept that in any complex system that you will have to use-experiences develop a small core of true System human Operators. “Chef’s” These men/women will operate by sight, smell, sound, touch-feel, and a seeming developed sixth sense of the system.

ALL functioning manufacturing systems, human service systems, depend on developing a dedicated core group of true Operators. These can be women. In my experiences especially women understand coordinating very complex cooking events out to successful conclusions.

The University types with letters in front and behind names Intellects are good at postulating possibilities.

The Design Engineers good at numbering out, in materials uses, applying the geeked possibles.

True Operators are what makes real works happen day to day, sustainable. Learn to respect this. Give then override operational authority. Or join 40 years of big biomass systems failures.

Regards

Steve unruh

Further to what Kristijan has described:

This whole thing is a process, all the way from growing the biomass to selling or using the shaft output.

You need to get control of those wood chippers or the chips that come from them.

I and many others on this site have had to deal with different kinds of wood chippers and different sources for them.

Although I am only a tiny user, I do deal with some of these issues here:

and:

https://spaco.org/Woodgas/WoodChipMeasurement.htm

and:

In my opinion, the chips from Drum chippers are generally inferior (Make smaller chips) to those from Disk chippers.

Dick Chippers with openings smaller than about 12 inches don’t make very good chips. I have never seen yields of more than 10" to 15% from the homeowner type of wood chipper.

Again, it’s a “System”.

Pete Stanaitis

Eccentric genius! I can see that!

When I was talking about woodchips a few posts ago, I mistakenly duplicated a link.

Here’s where the third link should have gone:

It sheds more light on the subject of getting the right kind of chips.

Pete Stanaitis

I own the gassifer and the engine.

Can i kmwo why all the drizzler are compacting the wood chips

Thanks made i think mositure is the case i have now stored about 2 to 3 tons of wood for about 3 to 4 days. we will see the progress

We have both a drum and disk chipper i never works out. We get the same quality of products mix of good and inferior chips

Uploading…But when we initially ran the system we had good gas but it was white in colour.

Hi Faazil, if I have white smoke, lets say in my hopper when I am running my reverse blower which pushes air the opposite direction. The white smoke rising up in the hopper like dense white fog will burn, but the flame is orange/yellow. It has tars in it and there is no black smoke coming off it.

If I try to light it running the gasifier in the correct flow direction out the flare tube the white smoke will burn if I hold a torch fire to it and keep it there. Same color and no black smoke.

The gas I want to see is a very faint haze type of wood gas smoke and it is almost invisible. Just a spark and it will light at the end of the flare tube and stay lit. The flame has more blue to it and some yellowish. It is very easy to light it with a electric striker no torch fire needed.

Bob

The device I think you’re refering to is not about compacting but to “meassure” the fuel level. A micro-switch tells the auger to run.