Yes its a open top gassifer. Yes the fire is on the top. All the raw meterial inside the gassifer is burning up when running, certain places catch fire the rest is burning slow or not bunt. Any reasons why the flame is colourless. CAN YOU ADVICE ON HOW FEEDING SHOULD BE DONE

Looks like a Makunda design.

Hopefully @SteveUnruh will jump in, he has read up on the Makunda systems.

Hopefully waiting for his answer

2 things have been said which I believe have a bearing on how this system (or any system) will run - the fuel size, and the moisture content.

It is important that the fuel moisture should be low.

Secondly, the fuel particle size. It seems possible there may be a problem with the rice husk material mixed in with the wood chips. Rice husks are known for high sticky ash content, and could be causing trouble with downward flow of material. They could also be partially blocking air flow leading to tunnels burning through the reaction zone, burning the syngas produced, and nearby having unburnt material falling too low, and creating tar. For an open top downdraft system to work right particle size and air flow must be very even. Through the bed.

Steve or others may know more, my observations are only from limited study.

I might suggest as Sean mentioned, removing material from the gasifier, and filling with dry charcoal part of the way to give good starting characteristics, then add dry wood chip fuel. Experimenting with chip / chunk size and moisture content I believe will be the key.

What is the story of this system - was it previously used successfully, and if so, for how long?

Good luck!

It looks a -lot- like the one on the cover of the downloadable pdf from this page:

If you read the brochure, they aren’t talking about the one on the cover, but the smaller one is a batch feed rather then continuous feed. It requires fresh, dried rice hulls to operate.

You -might- be able to make it continuous feed by making it an open top gasifier, which works a lot like a pyramid charcoal kiln. You get a bed of flames on top, then seeminly randomly add small bits of material to various positions on top of fire to try and maintain the flame. The drizzler actually had a pretty nifty feeder system, that may give you some ideas on what you need to do.

In my limited experience, in the open top gasifier, the fire will always burn upwards in the reactor. The reason is that the kindling of the material occurs where there is oxygen. And, the oxygen it right at the top of the fuel.

So, once the system is up to temperature, the kindling zone rises slowly, until it occurs at the very top of the fuel supply.

You have to do either of these two things:

- Make a way for the incoming air (oxygen) to be sucked in down closer to the hot zone toward the grate (this means that you have to close the top) or;

- Add only enough fuel to keep the flames down closer to the grate.

As Sean said, the “Drizzler”,(Luk Vanhauwaert) has taken this idea to a fine science.

Almost ALL of my tests with the Chinese JXQ-10 have ended when the fire burned all the way to the top of the fuel area. At that point, I think that most of the burnable gas was coming from the volatiles in the cellulose and lignin. That messy gas creates a lot of tar. I also notice that the above grate temperature drops when this occurs.

Again, I say that “Luk” and his drizzler have solved this problem.

Pete Stanaitis

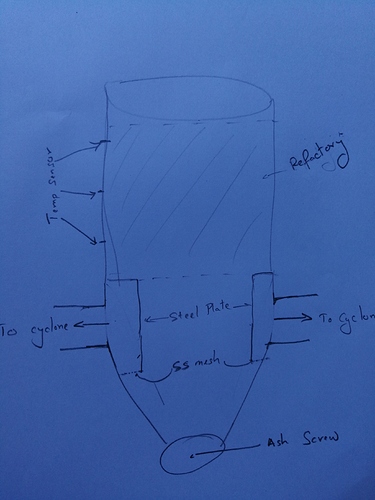

the open gas generator requires a well-controlled fuel filling, for the risk of surplus oxygen, it must be robust or have refractory concrete, so when you have a dry fuel, but I see a larger grain size for wood around 30x80, and a mix of 60% wood and 40% rice husk,

So to illustrate my reasoning, we say for computers, if we program shit, it comes out of shit, the gasifier is the same, a fuel with too much water prevents the heart of the gasifier to achieve high temperature for a good quality of gas, but the most harmful is that you reduce by two, see by three the life of your engine.

the operation of the gas generator requires a rigor of work, and to respect all the stages, it is at this price that the operation will be perfect and to be sure that everything is clean in the gasogene.

For dry wood, on plates, on a parking lot, on an asphalt road, ect it is not a problem.

dried dried … and everything will work out.

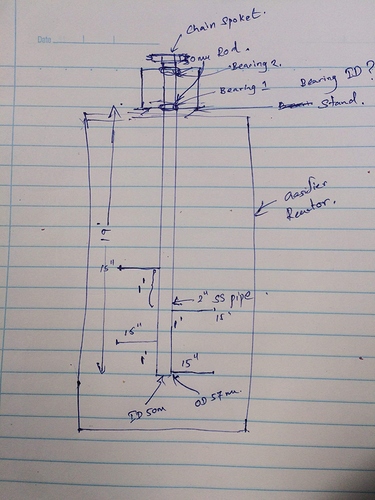

I for one would like to see a labeled schematic or cut away view of the innards of this monster before I could possibly offer

any comment. Well, one comment, “it’s HUGE”!

Pepe

It took me ten minutes looking at the blown up pictures to realize most everything is connected serially. Lots of cyclones with clean outs in the bottom. Maybe too many to get enough draw to actually work effectively. You would think even the dirtiest gas should have cooled off and separated with that many.

That seems to be the unspoken flaw in that Mukunda school of gasifier design, many cyclones and cooling to mitigate tar production. The vacuum / drag must be a considerable parasitic power loss.

I will post a detail drawing of the machine

You better see the engine i think its worth money i invested

The probem we had is tar is cloging up the air cooler tubes. i think every two days a full shut down is required for cleaning.

Faazil,

Can you give me some picture from around the gasifier as where the red rectangle is ?

a picture from there around the gasifier, so i have an correct overview from all sides

It is hard to imagine how you get ANY air flow through those tiny wood chips in an open top reactor. I bet they are very hard to dry, too.

I don’t use chips that fall through a 1/2" square screen.

Pete Stanaitis

The big flange is to light the up the wood and the small flange is given to poke the meterial if it gets clogged