Hi Sean & Kristijan, I wasn’t even entertaining the idea of ‘serious chemical distillations’ but the 1957 paper did cause me to at least consider what is chemically going on. I was just hoping to accumulate a bunch of pitch to paint fence posts with, or waterproof something like a concrete basement wall. But if the tar is so noxious without being further refined,… that it will corrode the concrete or wood…well that wouldn’t be useful it seems.

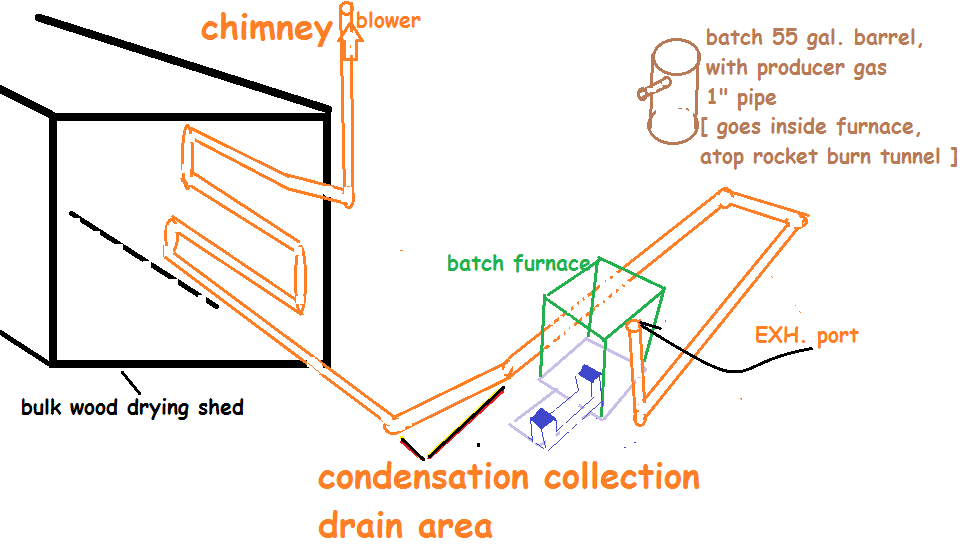

Before I read the paper, I already had this EXH duct excavated & installed, my primary purpose is to safely contain the flames from the furnace, so there is minimal chance of open flames. I just cannot have 20 ft. flames, not even 5 foot flames, my set-up will contain the flames in the EXH duct pipe, similar to a ‘rocket mass heater’. Of course, my experiment is outside, and I’m not using a riser & barrel in the same way that your normal ‘rocket mass heater’ would use…because I intend to produce charcoal, one [55 gal, or 30 gal.]. barrel batch at a time, which a ‘rocket mass heater’ doesn’t normally do.

As Kristijan has properly warned me earlier in a different thread, ‘moisture early in the batch is a cooling factor’, so I’m hoping to direct that early in the batch cooking heat thru the EXH duct, including heavy laden moisture/chemical/tar [unburnable] smoke. So I expect the dirt will eventually get hot, as the dirt is highly insulative, and it will take many hours to bake a batch, a good amount of heat is stored in the dirt, even on a snowy day. Once the 55 gal. batch is off gassing burnable fuel, that producer gas from the 55 gal. batch will be directed via a 1" diameter steel pipe & incinerated directly into the burn tunnel & therefore the brick lined furnace, to consume all the producer gas created from the batch barrel.

This diagram might give you an idea where I’m attempting to say.

The 1" pipe that vents the batch barrel, the 1" pipe will have two modes of use, the first is to vent wet unburnable smoke directly into the EXH duct pipe, for condensation purpose & heat transfer thru the duct pipe both into the ground, but also radiate heat into the ‘wood drying shed’, as the smoke eventually goes out the chimney, hopefully without obnoxious smell or smoke.

The idea here is to dry the wood shed bulk wood with air circulation and radiant heat from the EXH duct pipe, the more moisture I can drive off the bulk wood in the shed, the more efficient my batch process should become!

The same 1" pipe [vent] is ‘reconnected’ or changed in it’s secondary mode of which is directed into the burn tunnel, to incinerate the producer gas in the burn tunnel. This change is made after the batch is actually producing burnable fuel. The actual 55 gal. batch barrel/furnace is not moved or opened, the external 1" vent pipe is simply changed from dumping wet smoke directly into the EXH duct pipe, and changed to dump producer gas into the burn tunnel combustion chamber.

Now this may seem overly complicated, and it probably is…but thereagain, I simply cannot have open flames in my work area.

oliver