Hi All, one of these days soon I will have to build a new hopper for my truck. I am thinking, how can I be driving down the road and notice my hopper temperature is rising and simply push a button and add wood to my hopper, and keep going down the road. Sounds nice doesn’t it.

It seems like many times my fuel of wood starts to run out on the road where there is no place to stop and reload my hopper, like in town. So I have to switch over to Dino fuel and proceed until I find a reloading spot. This also causes the SWEM on my face to disappear, this is not good. It messes with all the good vibes that are flowing through my head while DOW.

I invite all members for input on this thread. Just try to keep it to hopper designs. Even though this hopper will go on a WK Gasifier truck, I will not talk about the WK Gasifier design. You can become a premium member to unlock those secrets and get the book, “Have Wood Will Travel” by Wayne Keith and edited by Chris Saenz. Thank you two for all you have done for DOW.

If you have a idea put it here for discussion. Let us start.

Bob

Okay you all. This is not going to be easy. So put on your thinking caps.

- I want it to add two or three bags of wood.

- To beable to reload this area by simply reloading the hopper lid opening.

- Have it contained to the same sealed hopper area. Simple operating and maintenance in a sticky and tary environment.

- Of course able to operate while driving.

- Not to interrupt with the operation of the hopper function of pyrolysisation of the wood in the hopper. Help dry and pyrolysis the extra wood in waiting to be used.

- This is new one to many and will be added to the hopper design. The VEVHD by Vevgen Kolvan (Joni) Ventura Exhaust Vacuum Hopper Device.

- I still will want the external gas cooling tubing with fins, on the hopper barrel and tar/water drain with the tar gutters inside.

- I will keep the big lid that Chris made for the hopper.

I will probably be adding more to this list later.

Hello Mr Bob .

I may give that a try . With wife in the back of the truck one honk of the horn means add one bag , two honks add two bags

Just in case you are wondering the wife doesn’t read the DOW.

That is the laugh of the day Wayne, you are so blessed with your wife. Would you believe Dana still has taken a drive in the truck yet.

Bob

My simple brain went right to build a bigger hopper instead of trying to auto feed a valve or something. Is there a way to build a bigger hopper that doesn’t cause a lot of wind resistance and doesn’t cause bridging?

Nope.

The larger fuel mass even if dry, dry will bleed out pyrolysis sticky goo’s and absorb rising combustion made moisture at sitting idles.

Sad. Sad. That three different across the world good-guys in the last 20 years put up in their hearth plans “make hopper as large as you like”.

Those who did mondo-make all hung up.

Sorry Bob. Nothing like hand-loving-care with raw wood feeding.

Stationary I gave up and settle for to 2-4 hours batch systems.

Steve Unruh

Jakob, I believe there is I want to lower my hopper down and still have more wood capacity in the hopper. I will be posting a drawing to view soon. It is time to brain storm. So if you think of anything post it here. I feel with the talented people on this site have it can and will be done. I have been thinking about this for years now. It’s time to post it up.

Bob

Hi Steve, I highly respect your knowledge in the world of gasification. Also Matt, Keith, Koen, Kristijan, the list goes on and on I could make a list up of 75 plus people, from all the books I have read and on this site alone. Wait here it comes,… BUT, there is something inside me that says it can be done and I can’t get it out of my mind. From the first time I ran out of fuel and could not stop to reload.

Knowing now that I can with my hopper hot and still cool the gases down on the out side of the hopper with my lower gutter on the out side of the hopper keeping it warm and draining the tar and water away to the holding tank. And still insulate the hopper keeping it hot, has all changed my thinking. With this Ventura Exhaust Vacuum Hopper Device that has been proven, I know the tar glueing affect can be stopped.

I made a promise not to show or to have any discussion on this tread about the WK gasifer. I will say that Wayne’s design in the upper part of the fire tube and lower part of the hopper is a great design in it self. Look in His book. I will not change that part at all.

If what I do does not work, I planning on making it so can be maintained or removed. I might built it to my present hopper. Before building a whole new one. It will just have to be a little smaller.

It took me over 3 years of redesigning the auto mixer on my truck that Chris designed and it worked but it would get out of adjustment, I finally got it to stay intune with the throttle body and run correctly. I haven’t adjusted it in a long time. Being Persistent made it work.

Bobcrazy

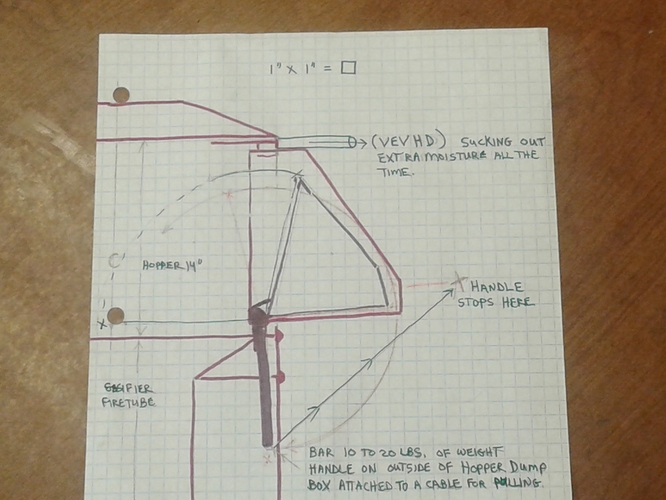

First draft drawing but not the last.

It is going to work like a front end loader, but the bucket has no sides maybe supporting bars on the sides for strength. Once the bucket is dumped it will be facing downward into the hot heat, if there is any wood sticking it should come off, it doesn’t stick to my walls in my hopper.

Moisture will always be getting suck out of the hopper by the (VEVHD) or the hot moisture will be cooled and condensate in the outer tubes down into the gutter and into the tar/condensation tank.

I figured the hopper dump bucket can hold 20 extra pounds of wood. That is 20 more miles I can drive looking for a place to pull off to refill.

I do use Wayne’s method for refueling. I shut down the gasifer to let it cool off a bit before refueling this requires going to Dino fuel when pull off the road.

One other thing I might mention is I always like to mix up my Rocket Fuel, wood and charcoal mix. More Hydrogen to burn.

Bob

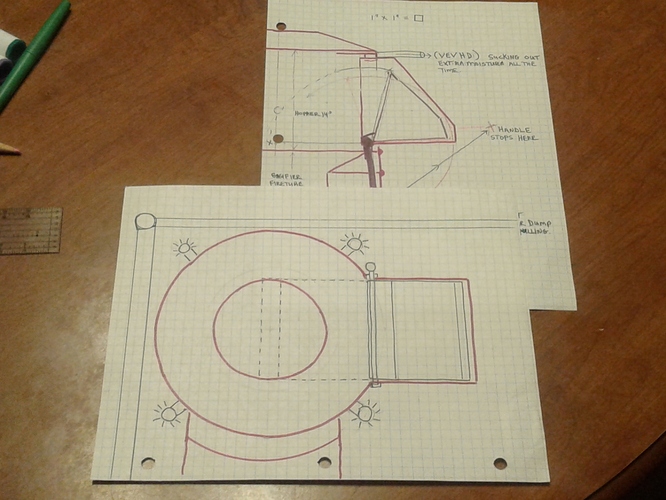

Next drawing top and side view. The dotted green lines is the hopper dump box facing down into the hopper above the fire tube the leading 2" edge of the box is over the hotest part of the hopper.

Bob

Bob, how about just hiring in @mggibb to be your second wife on longer trips? Honk, honk - two bags please

Good Morning BobMac,

if you read back I was mainly responding to JacobN.'s, " . . . doesn’t cause a lot of wind resistance and doesn’t cause bridging?"

Of course this can be done.

The one of the main reasons of the APL/GEK’s from Version IV on, tall offset side auger feeding hopper system was to do this. Avoiding putting the large fuel storage directly above the oxidization and reduction zones rising heat IN A HOT SYSTEM PARKED/IDLED situation.

You stopped for a long sit-down lunch.

Your wife insists you brake and stop for a yard sale.

Steve Unruh sees a roadside Historical marker sign spot: re-reads three times and lingers.

Beyond complexity, anything made will add bulk and weight. And the possibly of more fuel being in place starting to cook&sweat.

Nice idea on your drawings so far BobMac.

Uniquely different. Not height-adding. NOT requiring a whole fuel particle restructuring change to accommodate auger flutes.

What you’ve done is a separate last measure fuel reserve like in aircraft.

“on the fly” A bit of long trips talking with aircraft Michael Gibbs is paying benefits in your outlooks.

Good. Good. Something to be learned from all fields of endeavors.

Regards

Steve unruh

Ha! Ha! Now you’ve done it to me.

From the self-loading firearms fields all of the different systems tried and used is flashing thru my brain.

A side mounted pre-loaded horizontal revolving 4-5 segmented assembly.

Operated over an empty dumped segment.

Refueled by rotating in place a filled segment, self dumping.

S.U.

I have armchair thought of using the vehicle exhaust to feed into the top of the hopper and then a Venturi effect to remove this exhaust, moisture and tars above the nozzles.

Then just go with a mondo hopper.

The other method would be a electric solenoid controlled nozzles to pulse blast the hopper wood to break up bridging of the oversized hopper.

Wow this type of building is sure quicker cheaper and cleaner than reality!

How about extending that supplemental storage space to fit whatever size linear actuator you could find room for and then just pushing the fuel into the hopper with a flip of a switch.

https://www.google.com/search?client=firefox-b-1-d&q=surplus+center+linear+actuator

I would exted Steve’s idea to the “machine gun” with belt of prefilled shells moving on some sort of chain.

JO that is great idea. No extra welding on my part except a nice comfortable chair and seat belt. He loves to DOW, and best of all I supply all the wood.

There is room for two chairs and wood. A couple of bags under each chair, bags of wood for foot stools in front of the chairs. When Michael not around to feed my hopper, I can start a taxi service the fee. Honk, honk. Feed my hopper please, two bags thank you.

How about it Steve, I know you like to DOW.

Hopper refilling on the fly.

Not so crazyBob

You are right Michael, buy the time we are finished here on this thread we should have all the bugs worded out. Lots of input is very good.

Bob

Okay how will I operate this dump bucket?

I have always admired @mggibb Michael Gibbs electric boom hoist he built for his truck. It saves the back that is for sure. So if I install one to save my back putting heavy loads in my truck and when not in use, I can rig it to operate the dump box lever. Maybe Michael can post a picture of it on his truck.

Bob

Here is an idea. Instead of adding all this complications. Your gasser back there is making lots of excess charcoal right??? Why not build a small charcoal unit and use the char from the unit to fuel the charcoal unit.

When you need to switch, simply automate a glow plug ignitor with a start up blower to fire that up while your driving. I can direct you to a controller that is already programmed to do all this for 20 bucks and electronic valves. Then once it is fired up, simply hit a button and the valves will shuttle over to the charcoal unit.