When I get the Gasifier That Wanted To Be in the back of the truck I can put it the test to see if that unit can power my truck down the road. Thanks Matt for you input. I would have to figure out a way to make my unit smaller or have a two units in one gasifer, the charcoal unit on stand by ready to be fired up and be producing useable gas in couple of minutes.

Bob

I suppose we could try the refuel on the fly… BUT you would have to stop and be backing up… those fumes and fire when the lid is opened would disable the refueler!

The presence of firewood in the bunker is easy to control by the temperature of the lid - if the temperature starts to rise, then the firewood is running out. And why not make an auger, which will feed the coal from the ash pan into the bunker if the fuel from the bunker is used up? This auger should be controlled by a thermostat on the lid and, of course, a red lamp on the dashboard …

This concept will not affect the size of the bunker and the amount of fuel in it, but will allow the bistro to find a solution to such an “emergency” situation as stopping due to lack of fuel.

Hi Joni, if the auger is connected to the ash dump by a tube where there hot gases are being sucked to the engine, and the tube is connected to the hopper. There would have to be a flapper door into the hopper to keep the moisture from going directly to the engine, by passing the hot oxidizing and reduction zone. Trying picture this in my mind on how move the charcoal to the hopper but keep these two places isolated from each other. Great concept, if we can make it work. Thanks for your thoughts on this.

Bob

What about a separate, small charcoal hopper fed to the main hopper by a temperature activated auger.

Yes Steve, we are thinking on the same page. I am so glad you shared this. I did not mention anything hoping someone else would mention it. This is conformation to me. Thanks Steve. What is so great about this is there is no danger in producing tar. It is just bigger pieces on charcoal in the dump bucket that is added. Lump charcoal so easy to make no grinding to a specific size. Just built a fire and clean the ash off and use it. One of the things I have noticed when driving on wood is when the hopper is starting to get low on wood, my truck start to run better and stronger, it just performs better. This will last about 15 to 20 minutes depending on the speed I am traveling. The Question is why, it is because the wood that is left has been fully cooked the moisture is lower in the hopper. I know this because I have check the wood out in the hopper, not a easy task with all the heat come up out of the hopper at 190 *f to 230 *f more of a dry heat trying to burn my eye brows, It is just heat and not that moisture smoke to choke on that just keep coming out of the hopper when it is still half full.

This is why I am also excited about the VEVHD Ventura Exhaust Vacuum Hopper Device that will help remove some of the extra moisture in the hopper. It seems the quicker I get my wood dryed out and pyrolysisation takes place the better. My fire tube temperature does not seem to increase when I get low on fuel, the truck just performs better. It must be making better gas at this time of gasification.

Bob

Bob, normally I just add wood, DOW wherever I’m going and I don’t worry too much about power speed and efficiency. Still, I sometimes can’t help laying awake thinking about, for example, wood moisture  So, I grabbed my phone and checked some numbers on H2O properties.

So, I grabbed my phone and checked some numbers on H2O properties.

Let’s say we run a rig with no heat recovery and no hopper condensation or VEVHD. Then separate dealing with moisture in 3 stages and take a look at where the heat is wasted.

#1 Heating the moisture trapped in a bag of wood from just above freezing to boiling temp takes 10%.

#2 Turning it to steam takes 60%

#3 Superheating the steam through the charbed (net temp rise - leaving the grate at 1300F) takes 30%.

Many factors are obviously left out here, but should give a hint on where to focus.

The biggest 60% chunk of heat is used to turn moisture into steam in the first place, which suggests using as dry wood as possible is the lowest hanging fruit. I guess we already knew that, but it will also affect the 30% part in the same proportion.

Also, adding char would have the same effect as really dry wood, or even better since you’ve already got rid of even the chemically bound water.

Well well. Enough. This is what happens when you can’t sleep.

Good lining out the one of the keys to the energy budget J.O.

Some of the best papers in the last 100 years talk well on the energy budget of the wood fuel to ending gas products, very well.

None talk at all on the power effects of the latent water vapor-heat shaft energy LOSS in the IC engine.

And this IS one of the reasons for power loss gasoline to woodgas in our engines.

Oh sure, sure some of the knowing hot-rodders worship to the cold-in makes-more-power. True. At the trade off of less fuel to shaft power conversion efficiency. Much higher out the exhaust bad products emissions. NO competitive racing track, or limit exhaust emissions! Fuel on board allowed now yes. Ha! They run hotter now for better economy.

Now the engine efficiency-manics, and lowest emissions engineers know well now you must go hot, hot on the engine running AND inlet airs and fuels to achieve their chosen god’s approvals benefits.

Directly said.

If you put the woodgas into the engines still hot and humid, with the air equally warmed it will work just fine.

You will have maximum efficiency.

Not have in-engine cylinder washing. They are “dry” gasses after all. Not have oil dilution.

Yep as Jodi has seen and perceived you will pistons run hotter. But not damagingly so as he said.

And you will have less engine shaft power when compared to sprayed gasoline droplets. This giving the cylinder washing and oil contamination.

Propane and methane dry gasses give the engine shaft power losses too. Most focus on the C’s, H’s comparisons there too. Forgetting the fuels put in latent heat energy budget.

Delta T ,is Delta T in heat engines. Maximum power you want the widest spread.

Actual conversion efficiency, with the least adverse emission by products this is not true.

Of course I say this refusing to worship to the newest fashionable “god” of all-carbons-emissions are bad.

Worship this god and you by necessity must become a Nuclear power advocate.

Solar, wind, tidal cannot fully replace the worlds current energy needs. So then the slid into anti-humanist . Less people = less energy needs. NO people = no “unnatural” energy needs. Wacho. Coo-Coo. To slid into hating your own species. Becoming a Black Death flagellate.

Worshipping trees as a no-no-never-touch is like having edible cows walking the streets and letting your children starve and malnourish.

The contrasting extreme: consuming and eating everything. Locust illogic. Population burst out. Eating everything. Population crash. Leaving just enough eggs behind to do it all over again.

We’re smarter now. More aware.

Have wood lots. Human managed wood lots and forests. Managed for human use purposes. And it is human to manage the woodlot and forests for the wild animals too. Plantation single species tree converting sucks.

Wild animals are pretty to see. And some taste mighty good.

S.U.

In the USSR, there was a successful experience of filling a bunker with a mixture of raw firewood and charcoal in a ratio of 1: 1.

В СССР был успешный опыт заполнения бункера смесью сырых дров и древесного угля в соотношении 1: 1.

How does nature manage wood lots? It burns them to the ground in a constant cycle and generates healthy rebirth. Human management is seldom sound. Chernobyl, in 34 years has been reclaimed by nature. No six headed wolves. Salvation through mutation.

Thank you Steve, and very well said. Truth is Truth and this is good, there is no substitute for the good.

Bob

TomH I and my wife are members of the Forestry Farmers Organization in our county. 234 family/private timber/forest owners. None Christmas tree operations. A separate organization. A mono-crop.

And in my state of Washington this is only one chapter of over 3000 Forestry Farmers families/privately owned and managed for the growing harvesting and sale of timber products.

NOT the big boy private nationals like Weyerhaeuser, Publishers Paper, Polk and Talbot, Simson Timber and others.

NOT the actual State owned and managed public school Timber lands.

NOT the Federal Gov’Mints National Forests and National Parks forests.

NOT the Indian Tribes forest lands.

For all of these except the actually National Parks, a couple of designated Wilderness areas and one National Monument . . . .

all forests are managed to be 50-75 year rotation tree harvest crop lands.

These tree growing areas are rocky, hilly, mountainous and butt pucker steep.

Those of us born and grown up in this lifestyle are up against a sold Urban myth wall now.

We fully now after decades of being vilified as tree killers, expect now the Greenies street marching armed, open carrying to kill us.

They are not now satisficed with just midnights trees spiking, and equipment’s and shop burning. Vandalizing. And fuel spiking’s.

These 21st century KKK’s, Nazi’s methods emulators wear Green and/or Black. Hoodies and Masks. And alternately claim “science”, and Gaia as their gods.

Nature is not either of these. Nature is not gentle, kind, all knowing.

Nature is try, try, try 10,000 seeds starts in all ways to get one to take, grow and reproduce. Not the “strong survive” either. Another Culture spin on what C.Darwin actually wrote. Nature is very diverse and flexible. She knows conditions are always in a state of changing and flux. She diversifies so something will live and thrive; come what may. Icy Ball Earth. To fiery Earth. To atmosphere stripped earth.

Ha! Nature living things being found in all of these environments. Nature only cares about life. Not the shape or form of that life.

Human management is to culture grow the best seed stocks.

Replace plant 10-20 to 1 of a sites “natural” trees harvested. WE have mandatory State laws for this in Washington and Oregon.

Cull back once at 10-15 years. Thin cull again at 20-25 years.

Off our 10 acres of been 80-100 years growing we harvested 672 natural self-seeded grown trees. Replanted 2200 at non-aligned 11 foot spacing. Letting ferns, mosses and low brush to fill in. Expected to bring forward at 50 years instead of 67 to the acre; 100 to an acre to harvest. Each family/forestry generation can expect only one harvest money crop. So these replanted were not ever to be for the wife an I.

All of the wheat fields. Mono crop.

All of the vineyards. Mono crop.

All of the Urban areas. Mono crop. None: sure are not natural.

Manmade, And Man cultured, NOT allowing wildlife to intrude with the favored selected Mono’s.

This IS a culture war. And we will lose. But the real loss will be to the kids of the future. Locked out of being able to go out and work/live/families provide in the forest outdoors.

They for sure are being steadily culture programed to be Matrix plugged-in consumer-energy-units.

Tom reject this Green spin. Expect, demand, to die free.

Steve Unruh

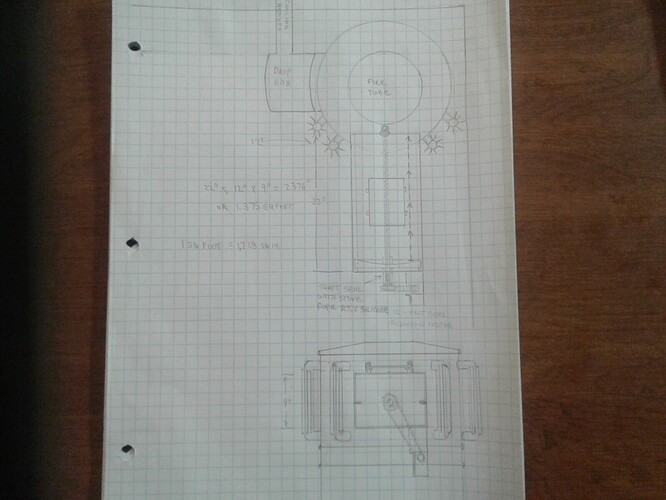

Okay @JocundJake, Jakob, here is my Idea for a box bulk hopper loader for wood. You will need to find a 1" or larger screw shaft with the nut that goes with it 1 1/2 " would be better. For what you want to do.

The rectangle plate has the screw nut on it. When the shaft turns the plate will move back or forward depending on which way the gear reduction motor turns. It will need some kind of limits designed in it or slip clutch.

I have very limited space on my small hopper between the upper and lower tar gutters.

Your hopper is square and larger. The plate has slotted guilds on eash side of the box. I made square hatch large enough to fill it to both ends and maintenance if needed.

Just a thought here, it might work if belt driven by a Motor and pulleys and the belt will slip when it limits out.

I think this design will work and can be bolted on to a hopper if it is square like yours.

The larger plate you build the larger the shaft will have to be. How big I don’t know. It is going to have to push wood chunks down a tary surface.

My box will hold 1.75 cubit ft. Oops. I put sq. Ft. On the drawing. Anyway it is about the size of a feed bag of wood 23 lbs. give or take. It will get you down the road further than a couple of road kill cats.

Bob

Simple limit switch.

Nothing like a green spinner Steve. Just saying work with nature within it’s grand scheme or get out of the way. Humans think they are in control. What was that Crocodile Dundee said about fleas thinking they owned the dog?

I like it Bob If I get anytime I might experiment with that. I have a few ideas along those lines, when I get time to draw them ill post them.

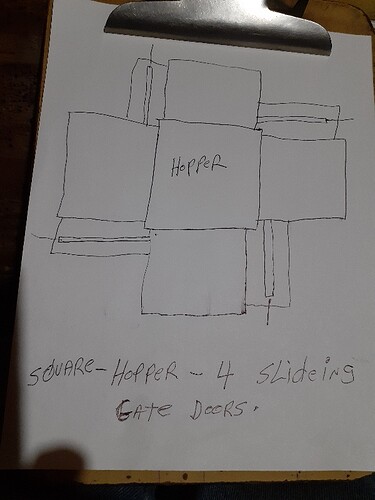

I like the idea of hopper filling while driveing as well.keep the fine tune ideas comeing, we might be able too get a safe efective design. I have a brain thought not yet detailed. A hopper as bob menchened short - with maybe 4 square tubes full of wood mounted in center of pickup bed for more room in tubes for wood.Each tube with a pusher plate pistons or screw operated.And then a slide plate too seal the tubes from the main hopper untill the tube of wood is being used too fill hopper. Then slide plate is closed and next tube goes in motion too add chunks too hopper as needed till tube shoot is empty. Any improvements or ideas wellcom.Tilt the tubes backwards a little too let any moisture run away from the burn zone.Maybe cooling fins like on the hopper cooling tubes.

How many times out of all woodgas trips do we really need fuel on the fly capabilities? If a hopper full lasts close to an hour of driving, that is way more than I need 99% of the time. Jakob could use one on his planned cross country trip but most of the time it would be in the way. My 2 cents thoughts on the matter.

Good morning Don.

I don’t remember having to stop to refill. When I refill I am already stopped for some reason.

Try riding 1500 mile trip with wife and you know what I am talking about

I agree a fast little stretch brake are not too bad most cases, then if you burning soft wood like i do it might need refueling every 40 minuts. I could handel 80 minuts though if it had not too many extra air leaks from an extra hopper shoot. Looks Good Bob mac, I can’t think of any thing better than a screw too move the wood with. A chain drive might tighten up from the tar build up. Unless the unit was more separated from the tar when not feeding hopper.maybe just pull over and use a handle too feed hopper leaving the top on hopper. Or a piston too rotate the shaft that chucks the bag of wood in the hopper.Less maintainable maybe.

Hi Bob good evening, just checking too see if you got any ware with a plan for hopper refuelingTHANKS.