I’m working on the ferret. and putting the gengas assembly back in, etc.

Do you have any ideas on what I should do with the gengas assembly, I think the tar can get between the nozzles, and the heat in the restriction is not enough, can I build up a cone from the restriction to the ends of the nozzles somehow?

Jan, I installed a smaller than the firetube diameter straight tube insert and longer nozzles back in October. Loose fit but stuffed with ash around it. The inner cone shape forms automaticly as usual.

Before I installed it I had a sticky throttle from time to time. Had to clean the tb with acetone once a month or so. With the new insert installed there’s no sign of a sticky throttle ever since.

I think this proves my charbed was simply too big to be able to keep the heat up with the amount of air the Volvo was able to pull into it.

Good idea, I’ll see if I can do something similar.

This one hadn’t started to build any cones at all yet, just a little build-up around the nozzles and I’ve been running it for 2 winters, very strange.

Now it worked this winter, but now that I’ve cleaned it again, I suspect it will get tar again.

Does this make acceleration better after a stoplight? Is this inner fire tube stainless? I imagine a layer of rockwool insulation would do the same thing?

Rindert

Hi Rindert! Yes, it’s a stailess 10" inner tube. The best I can tell the hesitation sympthomes at accelleration are now about half of what they used to be. Stop and go driving in town has developed from annoying to ok.

To shrink the firetube I guess any insulative material that can keep its integrity would work. Tube and ash was just the easiest fix for me at the moment. The idea was presented by SteveU a few years back.

Hm, I find that hard to belive. There has to be some debrie stuck on the restriction treshold towards the firetube wall.

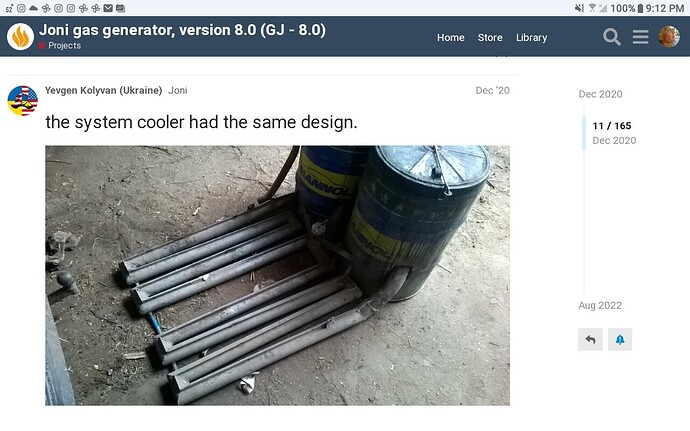

There is another later idea that has been used now for between the jets filling.

You can see this pictured up on @DeanL (Dean Lasko’s) 2022 “Newbie from Canada” topic.

Post #37. The fourth picture.

Welded on wedge vee blockers. This was a Ben Peterson developed feature. In his books.

Ha! I forget how to link to this post directly.

I forget a lot now.

It is what it is.

Steve Unruh

A working machine or tractor has its own characteristics in operation, for example, when you install a certain tool (plough, harrow, circular saw, trailer, …) and prepare for work, it can take a lot of time, while the engine runs slowly without load, gas consumption is very low. The gasifier thus operates with a very small load, the hot zone shrinks a lot during this time and here is the question, does this glowing rim cover the area of the limiting opening and thus prevent the passage of tar gases? If you cannot say this about your gasifier, then convert it. Another unfavorable characteristic is with a gasifier that operates in place and this is poor cooling of the condensation zone, you absolutely need forced cooling, this greatly affects the maintenance of the active hot zone. It is also interesting that frequent filling and keeping the fuel tank as full as possible also has a beneficial effect on operation, as this gives the wood more time to dry and pyrolyze and convert it into charcoal already high above the hot zone…

I looked at the dimensions that should be for this little engine, it should be 10-11 cm between the throttle and the nozzles (4"- 4.4") I have 15cm (6"), wondering if that’s the problem?

The fire tube was 30cm in diameter (12") and that’s according to the book. It works very well if I run on gasoline for a few minutes the first week after cleaning before I shut off the engine.

This winter I didn’t clean, and then I didn’t have to run on gasoline at all.

Edit: JO, when you reduced the diameter, did you notice any difference in power or top speed?

No, no difference in top end power. The idle at redlights and howering around parking lots is more reliable though.

No, it should be the ends of the nozzle that determine how much charcoal gets hot.

I’m thinking of doing this, I’ve built a cone with ash, if I put charcoal in it now, should it hold the ash until the ash solidifies?

I don’t know. What happens happens. To form a hard crust on the cone can take a long time. Some claim up to 50 hours of operation. Some tar drip would probably help with the crust, but at the same time we’re tryong to avoid that ![]()

Tar would have burnable material in it, as would charcoal. Ash does not. it is mineral deposits, silicone, etc. You probably want a binder for it, which a lot of times is a clay.

I was thinking about the unit in the ferret and the tar problem I had.

Could it be that before the ash forms into the long nozzles, the tar goes into the charcoal between the wall and the mouth of the nozzles?

Down at the restriction, has the reduction already made the heat too low to burn all the tar?

The solution is to cut the nozzles?

Does it really matter if the fire tube is long or wide, as long as the volume is right between the nozzles and the restriction?

Whether the grate is located just below the restriction or further down does not matter for the reduction (if the volume above is right)(the Russians have just below, right?)

Does it get hotter the fewer nozzles I have, but there must be so many so that the entire circumference gets hot?

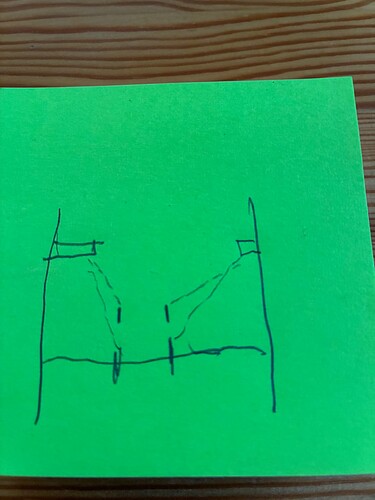

Correct me if I’m wrong, but as I remember it your Iller gasifier is rather big. Tar escaping behind the nozzle tips could be an issue, but shortening your nozzles would spread out and make your hot zone even bigger, right? How about putting your restriction on a cone pedistal and fill up around it with ash? That would shorten, shrink, insulate and focus the hot zone without having to shorten the nozzles. Quite an easy fix.

After all your V4 engine is only 1/3 of your Chevy and is operated only at high idle most of the time. A wild guess is it consumes maybe only 20% the amount of woodgas on avarage.

Yes, it is possible but don’t you think it will be like this, the cone will still be against the mouth of the nozzles?

And before the ash is dense, the tar will go behind.

I had something strange this year when I started driving, it ran fine on gas for about 500 meters then it was impossible, thought it must be a leak, and drove on gasoline the rest of the day.

Tried to find the leak, but found none, tested the gas at the generator, no combustible gas. Finally I cleaned the generator and removed some of the ash I had built up, put in larger charcoal under the choke, and filled in new charcoal above, then I got combustible gas immediately, let’s see how the next drive goes.

Hello Jan, the size or diameter of the hot zone is a relative (dependent on) thing, … First of all, it depends on the size of the fuel, which is located in the oxidation-reduction zone, if there is charcoal the size of walnuts or hazelnuts, a stable layer for tar conversion will be formed here. The question is, what happens higher up, does the wood convert to charcoal, is the condensation of moisture effective enough when driving slowly? We need enough heat for pyrolysis, and a sufficiently cold surface above. Joni made a gasifier with a very shallow area for his Opel 1.6 vehicle, where the distance was only 11cm in height. This method allows the air jets to reach the limiting opening (8 cm) and thus there is no possibility for the tar to escape the conversion.

Based on your reports, I would say that there are problems with the conversion of wood above the hot zone, perhaps the condensation is also worse. Many pieces of wood block the filled hot zones, creating a void and the risk of tar…

Thanks for the answer Tone.

Can you make a sketch of Jonis, I don’t remember what it looked like?

When I got tar in Illern, I started running on petrol for the last 200 meters, then the engine worked the next day.

After a week I tried it without running on petrol, and since then it has worked just running on gengas, there has been no tar.

Therefore I think the tar has crept behind the nozzles.

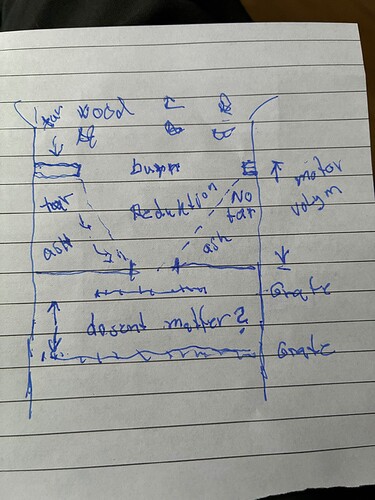

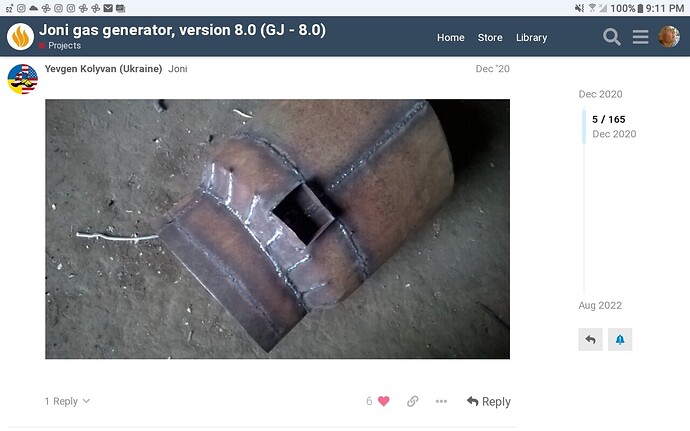

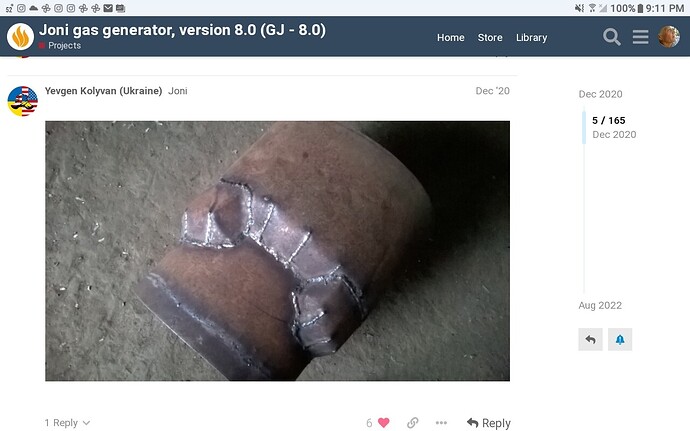

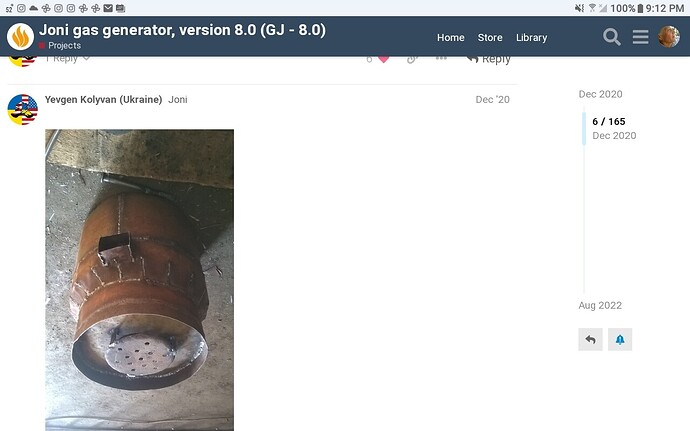

Here Jan is Joni diagram of his gasifier.

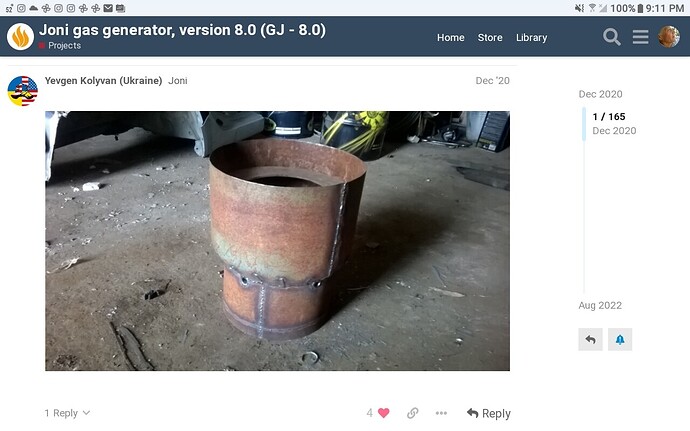

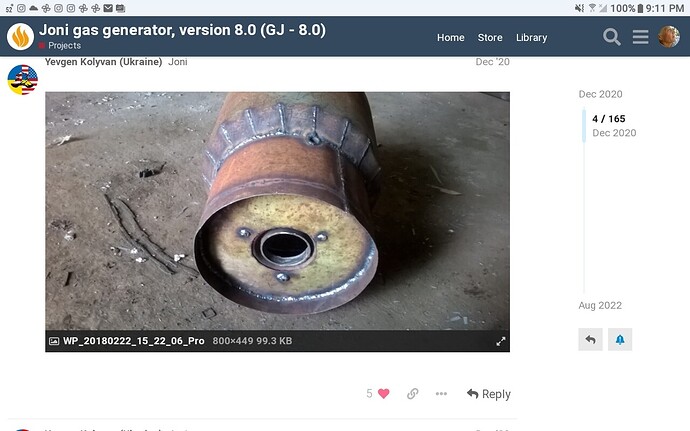

And some pictures.

Hope this helps you. I like your diagram and modifcation with the rised higher opening plate and ash built up behind it for more insulation and heat going down to the grate. This is the place that the heat can be at it’s highest and no tar can make it through if the gasifier is up to its operating tempertures. On my gasifier I want to see at the very lowest temperature of 800 °f or 426.6667 celsius at the grate. Operating under load I like too see 1472 degrees f or 800 degrees celsius. The tar is going to be cracked and converted at that temperature. Always make sure you are up to operating temperature. Any good built gasifier will pass tar if it is just to cold to crack the wood tar gases that are smoke. Moisture being to high in the wood is also a problem with a gasifier that is not up to good gasification temperatures.

Your original diagram looks like Joni’s gasifier but not sure if the math dimention are the same. I will try to find Joni’s picture of this gasifier when he cut this gasifier in half when he built a newer version 9.0 or 10.0 that is showing here. The diagram is the 10.0 design that he built.

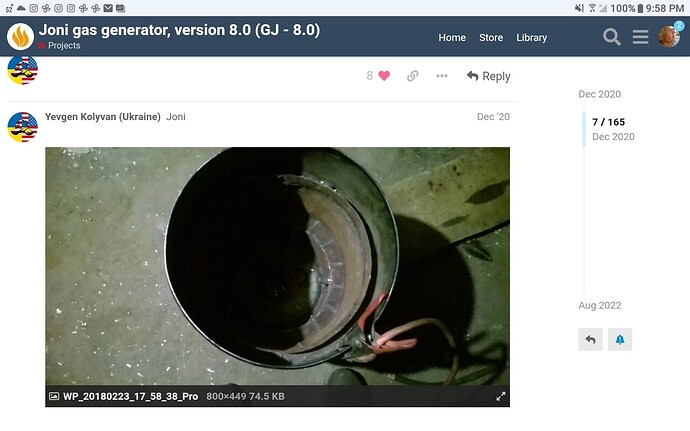

This is looking into the hopper.

Look at the size of the dry wood he could use.

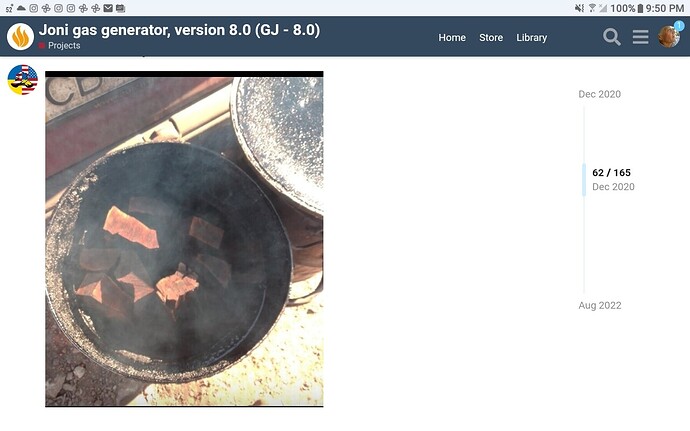

When he built the 10.0 gasifier he did a cut away of his old 8.0 gasifier.