I was afraid of that. I really hope the 4.3 won’t collapse spa hose. It’s supposed to be coil reinforced and it’s PVC material so hopefully it’s stronger than thin sump hose.

I noticed that Gary on his Ranger just leaves his bilge blower inline on the unit. How common is that for you guys, wood or otherwise?

I’ll try to use the least amount possible to keep it stronger walled.

Cody,

I hadn’t thought of using shop vac hose before for a gas supply line. It seems inexpensive enough and similar in quality to the sump pump hose. I believe I saw a 2.25 inch up to 20 feet long. That might work for a larger than sump hose diameter.

Well this Mazda I’m working on keeps giving me unpleasant surprises.

Big ol hole in the radiator. Was capped with plumbers epoxy. I had noticed some leaking last time I drove it.

I’m so glad this isn’t the only vehicle I own.

At least you still have the factory radiator so it’s an easy solder fix. If it was these new plastic tank radiators it’s a scrap and replace thing. Anything serviceable or fixable by the owner is a big plus in my eyes

I’m going to try to solder it back together. Hopefully the hole isn’t too big to try to do that. Might take a piece of copper and solder it to the hole.

Also waiting for the valve I ordered as a fuel cutoff to the carburetor. USPS has really been dragging their feet on a few of my orders.

Also because I hate the stock Weber air filters I ordered an adapter to use a Datsun style air cleaner. Maybe it will fit my original aircleaner or I can use the adapter to make into a snorkel.

Bought the adapter because it stands off enough that I could attach rubber elbows for a snorkel.

But I’m hoping the original Mazda aircleaner fits. If not oh well.

Found the bigger throttle body. I didn’t take this one apart. Might see if I can control how much it opens based on voltage via PWM.

I want to find a way to just insert this before the MAP/MAF whatever automagical dingus these OBD2 vehicles use. The space between the filter and the MAF has a vaguely airhorn shape so maybe I could slip it in and epoxy into place.

Or clip off the gearing and the return spring and use a bendy drill cable like how Bruce uses on his MGB

The electronics of the throttle body still works. Very touchy with a PWM. But that makes sense due to lack of a TPS or any other computer stuff controlling how open the throttle is.

Looks like it uses fewer volts than 12. Maybe not even 5 volts. My 18650 battery could smoothly open the throttle.

Going to see how much a low voltage PWM with voltmeter would cost me. I would really like to be able to control this electronically for the option of maybe metering based on lambda at a later point.

Found some really inexpensive ones on Amazon. Goes as low as 1.8v.

the PWM I have for DC is only as low as 7V input voltage but they obviously can output lower than that.

I will try to see if I can fiddle up an 18650 powered controller for this.

The location where I want to insert this in the Sierra, if I have a serious malfunction I can just disconnect the air filter from the intake tube and drive like that. Worst case scenario.

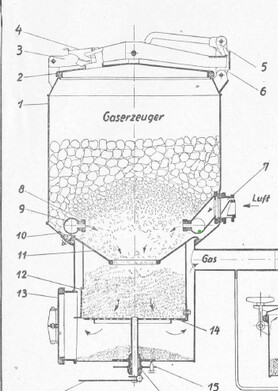

I keep looking at the Wisco gasifier made for Opels. And I keep looking at my oddball 20 gallon drum and propane cylinders. And my pipe benders. And those piston wrist pins.

V shape indicates inverted angle iron grate, the lines indicate jet angle in an upwards fashion as Joni has prescribed to others before.

The air will come in a pipe ring like I had imagined before. I’ll just have to do it in sections with my less elegant plumbing pipe hydraulic bender instead of my ring roller. I plan to make the pipe ring fit as far away from the active lobe as possible using those wrist pins as nozzles. I noticed very stable temps in an upward direction as well.

I would really like to see how much wood I can mix in with this design not only to keep the reaction cooler but also add hydrogen without the need of a drip.

I will most likely weld heat sinks to the burn tube not necessarily for preheating air but to protect it some. I don’t have another 20 gallon barrel or similar sized cylinder to preheat and I want to maintain the 12" burn tube diameter that the propane tank has.

I also would like to make use of thermal energy by placing my drop box inside this aluminum truck toolbox. I could double up the use by preheating my intake air inside the dropbox and also maybe preheat any wood or dry out charcoal that I would store in here to keep moisture away.

I guess in this design it’s less of a Charcoal Gasifier and more or less using charcoal as a Tar Catalyst. I like the way that sounds but in reality it means I’m lazy at design

Cody you seem to switch back and forth between what wants to be wood gasifiers and want wants to be charcoal gasifiers.

Here are three plates of dimensions for your internal air-ring type:

I think pure charcoal would heat kill your air-ring.

Actual charcoal gasifiers use internal charcoal to radiant heat shield the system metals from active charcoal energy release damage.

Wood gasifier use the woods humidity to heat moderate.

Hundreds of pictures and system diagrams have been put up on this topic by Chris Seymour and Francois Pal and others.

S.U.

I’m just throwing my ideas out so I can look back at it. I will attempt to build this with 100% charcoal in mind but I would like to at a later point see how much wood I can blend in for emergencies.

I’m one of those kinds of people that can’t get their idea out without having to say it to someone else even if they don’t respond to it.

It still boggles me how the Mako could survive with their air ring. Their jets face downward a little so maybe it is blasting the heat away as much as possible as well. But that doesn’t add up with my results from the double flute and it’s downward jet angle testing. They only had kanthal on the tips of the nozzles as well.

This random idea could just be a side project for when I’m stumped on other things.

I eyeballed a donut rim that looks like a really close fit on the 20 gallon drum, could use that as the air inlet.

I just don’t know if this idea would warrant making a new topic, I’m just using this one I made as a containment unit for my madness

Bigger priority is my Svedlund adaptation, it will be much more simple to make.

What are the advantages of a charcoal gasifier against a for wood?

I understand that it is better for small engines and if you do not have space, for cooling and cleaning.

I would say the main advantage that I can think of is the lack of tar. The only cooling you need for a charcoal unit is to actually cool down the gas to save the filter instead of dropping the temp down to dew point to drop moisture.

Also the cooler the gas is the more of it will fit in the engine. that tends to be the limiting factor on power is getting enough gas in the engine.