Cody I don’t understand why the ring has to be pulled away from the fire tube? I definitely missed something !

only the tips of the nozzles are exposed to extreme heat

If this were for a 100% charcoal build then during shutdown the pipe ring might be subject to too much heat. That’s my thinking at least I am probably dead wrong.

It’s just a one-off idea that I had. Something to tinker with while I’m waiting for other resources or inspiration on the Svedlund build.

But surely once you shut off your system and starve the gasifier of the air the system will cool down anyway , its how every system works in my eyes , i sort of understand what your thinking here about the blast will keep the heat away from your ring/nozzles while running , but then once there is no blast your ring and nozzles will get extreme temps and start to oxidize , but once shut off and with no air leaks the system should start to cool down pretty well and maybe if you were to lower your demand on gas just before you were about to shut down anyway you might be able t drop the core temps anyway.

Dave

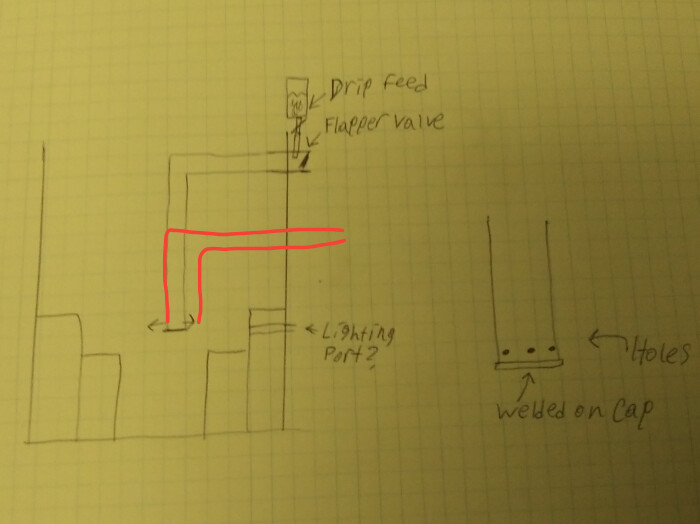

Like I said earlier this two barreled idea is just a side project so I am headed back to my other charcoal reactor. Going to try to build my Svedlund idea using side exiting holes and a welded on cap on the end of the pipe. I still have a good bit of ceramic wool so I will use that as my hearth and insulation. I’ll try to go with two rows of five 5/16" holes making ten total holes. Hopefully this will give me enough air volume to run one of my engines. The jets will just barely enter at the top of the wool burn tube. I won’t be able to make an hourglass shaped hearth like the original Svedlunds did but hopefully that won’t matter.

In my original drawing i set the air pipe to stand way too tall. It was just a rough sketch but hopefully it didn’t give the wrong impression.

I’m thinking that 2"npt would be fine for testing purposes. I will be adding a water drip to this unit to keep it cool, which is the main reason why I decided to cap off the nozzle end. Would give a hot plate effect for the water to evaporate off of.

I’ll try to get the plumbing I need tonight and come up with more intelligible representation.

The construction of the nozzle will be a 2" coupler at the wall welded to the barrel, then a nipple, then elbow pointed downwards and another nipple. I wanted to use a screw together system for easy replacing and I also wanted to see if i could lower the blast effect that the open nozzle Svedlunds had via EGR since EGR seems to cool reactions down.

Hi Cody[

I can’t wait to see a central nozzle like the Svedlunds. A one piece pipe would surely be a better heat conductor to extract heat from the nozzle tip. But I understand that an assembly of plumbing parts is easier to achieve

I was thinking of your Svedlunds nozzle looking at that crooked post of my loader. Maybe I could recycle it in my next gasifier?

Never say never with Obtanium.

Also great news! The air cleaner adapter for the Weber carburetor fits the original Mazda air cleaner just right. This will let me introduce the chargas in there and use the original air filter as a sort of dust failsafe. I’m going to try to make sure that won’t be an issue but after taking a closer look at my intake manifold the EGR is baffled by where the coolant runs through. I’m assuming it’s so both the egr and the hot water can help get the engine warmed up faster and something with emissions I’m sure.

So I won’t be able to do a secondary throttle in the Mazda and will just have to be extra careful running it through the carburetor.

Also with a straight down pure Svedlund reproduction kind of build. I seriously think EGR will tame the jet that it supposedly blasts out. According to the Gengas book the Mako company originally used a straight down central jet but faced issues with the blast blowing holes in the grate. Not sure if they experimented with EGR to bring down the reaction or not but it’s worth a try. A few extra hydrocarbons never hurt a char reactor anyways.

On the downside for the Mazda, I couldn’t patch the radiator. Going to look for a replacement radiator. I might send this truck to my mechanic for a rebuild. He’s a family member and is better with the older stuff like this old girl so I can trust him to fix it up.

Would be best to DOW-convert a truck I know will last another 200 thousand miles.

Has anyone used those spa PVC gate valves that are a simple push-pull adjustment? Ordered a 3" sized one for air adjustment. Supposedly rated for 50psi hope that works in negative pressure as well!

Those are not unlike the ones Wayne uses as air inlet controls and vent controls, I’ll be using them on my build as well. Meant for RV sewer dumps, cheap and easy to get and air/liquid/ gas tight seals

That seems awfully big to me for air adjustment. On second thought, it operates differently than a standard butterfly so it might still be okay for fine adjustment.

The air intake on my Sierra is a tubular construction and is roughly 3". I wish it had an air cleaner pan like the older ones but it has a filter box at the end of the plastic tubing. I didn’t want to choke down the air inlet size for when I’m driving on guzzoline and affecting performance.

I’m really jealous of Gary’s Ranger, he was able to put a damper on the inlet of his filter.

My idea is to just tie in a choke cable on there since its a straight up and down adjustment instead of twist adjustment.

I might be able to use a Vernier for finer adjustment.

Hi Cody, on my truck I use a 2" gate valve and a brass 1" ball valve in parallel for fine tuning the air.

I open my two 2" wood gas valve when driving on gasoline or close the 2" gate valve when driving on wood. My auto mixer valve goes the rest with a 1:1 air/woodgas ratio. I use the ball valve to adjust my mixer when hybrid driving on wood/gasoline for more air. The 2" gate valve is hard to adjust for air mixing it also makes a whistling sound that Drives Me Crazy. DOW yes but not DMC going down the road.

Bob

Hello Cody .

I’m with Mr. Bob .

I think it would be very difficult to control the fresh air mix to the motor with a 3 inch value .

I’ll try to step it down to a 2" valve. I just hope it doesn’t throw off my MAF sensor.

Cody, the MAF only cares about flow. When running gasoline, a downstream restriction may decrease power - but not alter the mix. More important is to make the woodgas valve seal 100% - or air will bypass the MAF through a cold gasifier and cause a lean condition when running gasoline.

I agree with Bob and Wayne that 2" should work better for a mixing valve , but I’ve used 3" as well and I couldn’t tell much difference in “pickyness”.

Btw, a long tube from MAF to throttle body is perfect for woodgas. Then you have plenty room to install both mixing valve and woodgas entrance.

I have plenty of real estate to plumb in my producer gas lines that’s for sure.

It’s one reason why I keep coming back to my Sierra. The Mazda has a piling number of issues with it that need addressed before I can put a reactor on it. In the end for the Mazda I may go straight chargas no guzzoline for that one. The air filter adapter for the Weber is leaving clearance issues with the hood but I could just reattach the original carburetor and plate off the mechanical fuel pump, and drain the fuel tank of course. Could give me room to make a taller unit and integrate with the bed if I remove the fuel tank all together. The Mazda doesn’t have much value to it besides personal attachment.