Mr. Tone; I don’t know if you have read it before, but anyone who has and uses a gasifier, has said at sometime or another, “the secret to running a gasifier is 75% operator knowledge and 25% gasifier design and construction.” I suggest you take the most simple proven design (as much as any are proven for universal use) and construct it using the BEST of your talents. Then, go through learning as much of the 75% that can be learned, until you have reached a sufficient ability. And then, think about building something of your own design. I mean no disrespect. Just trying to point out the importance of the operator over the designer. TomC

I must say l agree with Tom here. It is good to start by making a good clasical lmbert first, to establish a baseline. Then, by trying out new ideas one at a time, make it better! Afterall, if you dont know how a “clasical” gasifier performs you can never know if your design works better, or worse…

I think l remember counting l built 11 gasifiers for my 3 woodgas cars and only now l am starting to get a feeling of how a good woodgas system looks like  and thats not counting the litle differences like hopper designs, coolers, filters etc…

and thats not counting the litle differences like hopper designs, coolers, filters etc…

Or even the material you put in it for fuel. BLM (black lumps mostly).

Is it possible to translate these texts in any easy way?

http://runeberg.org/tektid/1945/0826.html

Thanks Steve.

Did I understand correctly if I said that the important height is from the nozzles to the bottom of the fire tube?

The height of the restriction is not so critical?

I saw that under each page there is a text that works to translate with google, if anyone is interested in a Monerator from Finland.

http://runeberg.org/tektid/1945/0827.html

Good morning Mr. Steve and thanks much for referring to Jan’s article.

Below are a couple of short clips experimenting with moist fuel. Sorry there is no snow balls down here to test as was in the article.

Once Mike Larosa was visiting and I was showing out and did the same as in the below video . He dare not do the same and didn’t think the truck would run but I drove him about a 40 mile trip to the liquor store and it run like a top

Just because this water is going in the hopper doesn’t mean it is going through the motor .

You have to go 40 miles to get to a liquor store? For sure you aren’t in Michigan.

Yes Tom

At that time our town didn’t have a liquor store but the near by town did . That also where the jail is located

Sounds a lot like Grand Isle, VT where I grew up. We had a gas pump, but then they changed some law about the storage tank and took it out.

Rindert

As I said, I intend to use the gasifier for a stationary unit, first adding gas to the diesel engine, this I managed to assemble these days, …

Wet wood in a gasifier is really not welcome, energy for pyrolysis and reduction is lost to drying the wood and evaporating the water, which is then cooled and condensed, literally discarding some of the energy from the high temperature. Kristjan and I talked about it and our goal is to retain as much energy as possible with the high temperature in the carburetor, hence the double coat and the outside insulated to the top. I intend to cool the hot outlet line in a heat exchanger, where it would overheat the air for total wood drying before entering the gasifier.

Good morning Tone .

I agree with you 100%

What I was showing in the above video is if caught in an emergency I can still go even if no dry wood is available. .

I try to use wood as dry as I can get it .

Hello Wayne, I admire your work. I am thinking about the construction of a heat exchanger, hot wood gas / air for drying chips, and before entering the funnel, I am wondering what is the temperature of wood gas usually at the outlet

Hello Tone and thanks much for the kind words .

I consider 800F to be the normal gas temperature leaving the gasifier and before the gas reaches the heat exchanger.

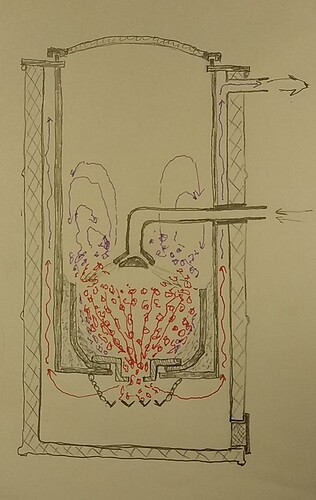

I got two cast iron drums from the brakes of a smaller truck with a diameter of 300mm from a neighbor, and at home I have several brake discs that fit nicely to the drum, I think this would work nicely like a glowing heart of a gasifier. I drew a cross-sectional sketch again, a 200l metal barrel will be used for the outer coat, and the rest will be made, … maybe some suggestion, criticism, …

Hi Kamil, I hope it works as expected, otherwise I will be able to easily replace the internal elements, the disc, the drum, the blow nozzle, or replace it with a tube ring, as Robert plans at Joni’s suggestion.

Wood chunks like to bridge in an open 12” burn tube, so having the nozzles stuck out in the center will cause more hang ups.

Mike,

What you say makes sense. But that’s that way Joni does it. And SUCCESS.

So what do we do in a case like this? Maybe just say it works.

Rindert