Hi Garry,

Love reading and following your argumentation. Man i would give an arm and a leg for being able to express myself more correctly using english.

Being addicted to researching all about the Co2/energy impact on the worlds environment i would help a lot.

To the point off using or not cultivated timber instead of concrete.

How would the same argumentation uphold for the production of concrete ?

I have several case study’s, CTG, ( Cradle to grave) which indicate exactly as i stated earlier.

Same argumentation we should use for all kinds of energy uses.

The outcome would be predictable dough: using wood, cultivated for the purpose , wins all the time.

Used to compare: the equivalent of Co2 sequestered, bamboo has a positive impact of 12,2 Kg Co2 equivalent.

And it also produces oxygen.

Maybe, they should use biomass waste and or extra cultivated three’s as energy source for the concrete, leaving charcoal as residue to use in automotive ?

As i would love to express… i am 100% advocating the use off gasification as fuel for automotive and power generation.

Hence, my work here is exactly that; using the Bamboo 100% , for food, clothing, building materials… and finally producing energy.

Looking forward for further positive views in your writings.

Regards

Koen

Hi Garry, those old mill ways are dying off. Now a days the portable band saw mill is taking over and the swing saw mill can go right to the log. Milled right on the property that the lumber will be used on and all this can be fueled with a small fraction of the wood waste.

I tried building a small shed with bails but it was hard to insulate because you need perfect shaped bails. Wood works soooo much better, it’s our best gift from nature or god, or God or what ever.

My previous post got moved to straw bail … I know several people that have stored and used woodgas including myself … I’m re-posting below about Bruce Jackson … Regards, Mike LaRosa … They actually laid my buddy out today … I got to pat him in the shoulder a few times … (ice cold) … His daughter said she’d give me some ashes after they burn him up to sprinkle on the RR tracks in AZ … cool … Hope I can get back there a few times before I get the axe.

pasted in

Money, What’s money … Happy New Year folks … Have to go to a wake of one of my best friends tomorrow. Gonna be boring now and he was 3 years younger than me … As far as storing woodgas, the only person that took that seriously that I can recall is Bruce Jackson , I can’t do youtube but I think he goes by budasdad or the such there and you can find the videos of his gas storage adventures and many other woodgas things … Regards, Mike LaRosa

I watched his video, nice. The H engine is about the engine that’s in my 300. Sounded good…

Putting some real life Charcoal gas in a real life tank…

Testing a setup to be used in multiple ways, trying to avoid the obvious…

But hey, they do the same with cng and put in a car…

Anyhow, as usual, its fun to do and fun to observe the outcomes…

The airpump is rated 120L /min, tank is 25 Liter size…

It takes about 2 minutes to reach the 8 bar mark, so average 100L / minute

(if my math is ok, then 25 Liters times 8 bar is 200 liter)

The 200 liters burns in a cooking stove unit … indicating how much energy per minute flowing…

Surprise  its not as long as some people on youtube claim…

its not as long as some people on youtube claim…

To be continued…

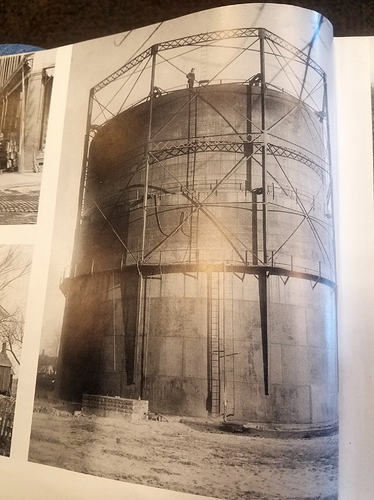

I was at the optometrist waiting room last week and they had a local photo history book that I was browsing through and I came upon this picture of a town gas storage tank that my dad showed me when I was 8 or 9 years old.

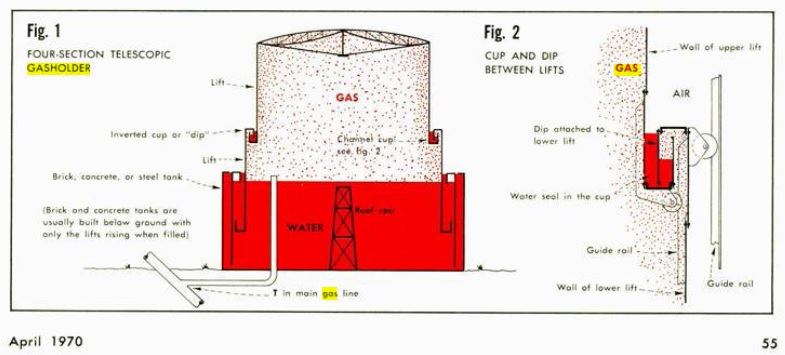

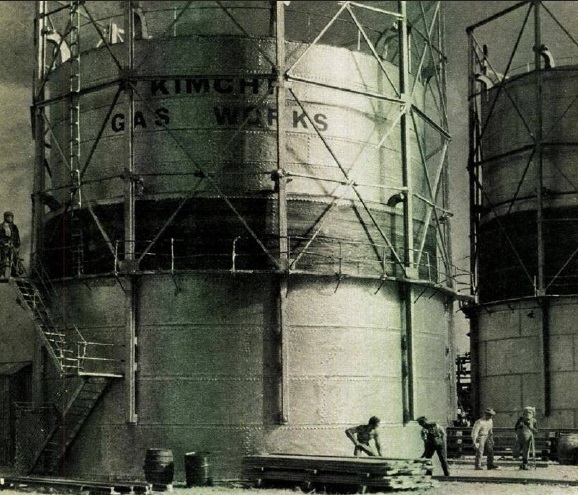

It was coal gas, not wood gas and it consisted of two tanks with the top tank riding on a water seal in the slightly larger diameter bottom tank. As the gas was pumped into the top tank, it would rise up in the frame and the weight of the tank would provide the distribution pressure between fills. The man standing on the top gives an indication of the size of the tank. That picture brought back memories of 65 plus years ago.

Thanks for the memory Don. We had one of these at the coal coking plant here. When the family that owned the coking operation had to close it down they sold their city gas operation to a pipeline outfit.

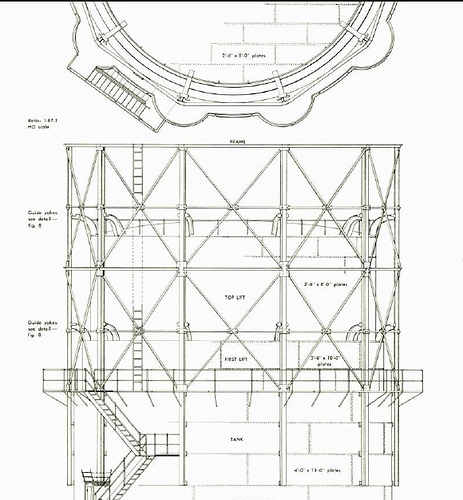

From Model Railroader magazine, April 1970. Article by: John Allen, Kimchi Gas Works. Copyright maintained by Kalmbach Publishing Co.

In the 60;s in Long Beach, Ca there were a lot of these for storing oil. The wells were out in the ocean and they piped the oil up to these tanks for storage. Last I saw they were ALL gone.TomC

Tom,

Sweden has no oil of its own. I resently read, and was surprised, we stopped buying oil from the Arab countries decades ago. Norway and Russia are our main suppliers now.

However, we have way more refining capacity than we need. From the low grade, high on sulfur Russian oil, we apparently make gasoline and export it to the US.

Keep your wallet open and keep lawn-mowing

Yea, I have heard that Sweden has no source of oil. I think I heard that during WWll, they ran their vehicles on wood. What a crazy idea, that was. A few over there still think it can be done. TomC

It must be recognized that in history there have been some explosions of gasometers, but mostly due to poorer materials than at present, but given the history, the public authorities do not give their agreements for new achievements,

here is an example of a gasometer that worked perfectly.

So, long term storage/ease of use (maybe) idea, along the lines of “charcoal IS the storage.” What about bio oil, a liquid fuel gasifier? Yes you would still need the charcoal for a char bed. Something like the Riche’ combustion gasifier Francois posted, but with a waste oil burner in place of the wood combustion portion. The blast gets the char glowing, then the carbon starts steeling O from the H2O and CO2 etc. You know the rest.

So why go through the hassle of processing wood into oil and char and not just gasify directly? I’m thinking potential faster response times to load changes. Maybe cleaner gas since it has been partially broken down already. Easy to handle liquid fuel (only a small amount of charcoal is consumed). Oil and char don’t rot. Easy lighting, could even have a pilot light so it can kick on when needed. Faster warm up time. Potentially smaller unit. Less wood processing (retorts aren’t partial to wood size). Multi fuel capability (bio oil, diesel, kerosene, crude oil, waste oil, etc). Possibly some other advantages I’m missing.

Just an idea.

A long time ago a fellow was selling gasifier plans. He also was storing wood gas in an ag bad that was standing in end in a wood frame. The wood frame was a minimal structure.

I realize this topic is closed. I am not trying to stir up any interest. I had one of those “ah ha” moments just now, and unlike twelve years ago or whenever, I was able to instantly look up Linde’s spec sheet for carbon monoxide. Linde is an Industrial Gas suppler. It’s their business to know if a gas will react in a tank.

Linde sells semiconductor grade carbon monoxide gas @ 2000psi along with varying grades of less pure gas all at 2000psi.

I never could quite refute the arguments that CO under pressure would revert to CO2 And Carbon…even though there is no activation energy in a tank, and that reaction goes the wrong way energy wise.

Why care? The big weakness out here in off-grid bush land is and was always batteries. I have buy at least on new battery every season. Now with the bigger diesels it’s two $200 starter batteries. I have always been looking for a way around that.

The method that worked best out here was simply putting 10 ft of flue pipe on the loading port of my down draft producer, turning it into an updraft wood stove. Lighting the port with birch bark usually offered enough volatility, to start a low draft fire. Once it was thoroughly burning. I would haul down the flue, close the hopper port, shut all but one tuyere, and run over to the front of the tractor and start cranking. If all the stars lined up, I could get the tractor engine started before I was worn out from cranking.

I always wanted to just open a valve and do a quick crank, and “Ta Da!” I have the engine running.

I still think there is merit in storing this gas under pressure. I am encouraged by the fact that one can actually buy it.

Please don’t try compressing carbon monoxide yourself. Linde produces and sells gases on an industrial scale. They have the experience and technology to compress carbon monoxide (CO) safely every time.

I can’t see how a DIY person could be safe compressing carbon monoxide, ever. Carbon monoxide is flammable over an incredibly wide range of concentrations: generally quoted at 12% on the low end to 75% on high end. That’s the range of fuel gas and air mixtures that will burn (explode). On the lower end, that’s where it’s too lean to burn. On the high end… that’s where it’s too rich to burn. Let’s focus on the high end number because that’s the situation if you are looking to compress fuel gas in a tank for storage:

Methane/Butane/Propane are consumer friendly fuels for good reason: the upper end concentration that’s flammable is much lower, like over 15-20%+ and it won’t burn. Even a rather contaminated (with oxygen) storage vessel would not be flammable (IE explosive). The same levels of air mixture with CO would be tremendously dangerous.

As a fuel gas is compressed the amount of safe oxygen contamination decreases. Said another way… . that 75% upper end for CO goes higher still, decreasing your margin of safety. I can’t find a table for carbon monoxide flammability vs pressure but for methane 1 atmosphere to 50 atmospheres increases the upper end flammable concentration from 14% (1 atm) to 40% (50 atm) to give you an idea.

Maybe you could start the diesel engine with a pneumatic driver connected to a simple compressed air tank. I’m not sure the tank would be small enough to be portable but a good sized stationary air tank and a length of air hose might get you where you want to be. Many industrial engines are started with a compressed air motor so it’s not a crazy idea. An air tank is happy to sit idle for months at a time and doesn’t wear out like a battery.

Alternatively - use lithium batteries… they have much better surge current than lead-acid anyhow and last a lot longer. I have a lithium ion battery that will jump start my car. It’s about the same weight and size as a paperback book. They don’t like temperatures below freezing (esp when charging) but otherwise are pretty robust.

This was the last time I compressed producer gas.

The most pressing danger is getting a whiff of the stuff. It is horribly bad for you.

As I recall, the longest I stored gas was three months.

It was a pretty complicated process.

We didn’t do it out here because we never had shelter for all the equipment.

I always like the old Cat pony engines used as a starter. It also warmed the engine. A long time ago I had a huge Allison natural gas engine on a sawmill. It had no starter so it was cheap. Rigged up a hydraulic motor on the front of the crank shaft to start it. Boy, was that thing loud. Swear that the leaves on the trees would vibrate for miles around.

Jeff,

There are a lot of those caterpillar engines around here

I think this one is $2500.

There was a TD14 from back when IH had those engines that started on gasoline and the there was some sort of lever one pulled that did something to increase the compression and then it was a diesel engine…it had been in storage for 50 years. All those different ideas were for operating in the cold here, with no batteries.