Hi Matt , i’m well impressed with this machine and how you have managed to get it into a nice compact unit complete with wheels to be able to move around, cutting edge design as far as i am concerned .

Trying to work out in my head if this is a straight cross draft or have you a lower outlet pipe to give it the best of both worlds , so much being talked about on so many different idea’s right now , and i guess you will want to keep a lot of your idea’s it in house for yourself .

Anyway nice one .

Dave

If is a semi cross draft. However the gas must go straight down and through the grate and into the ash collection / clean out chamber before it can enter the pick up tube. Its hard to see, but there is a pickup tube, in there and brings the gas all the way back up so it can enter the filter that is also inside this unit.

It is more of a down draft than it is a cross draft. This why I originally called it a diagonal draft unit.

Air enters the side but at some point it has to migrate down to the bottom through the grate.

Thanks Matt , helps a little better with my simple mind to picture it better now .

Its still pretty amazing that your grate must be getting a pretty close blast from your nozzle and yet it looks amazingly intact , i am guessing that is due to your steam injection helping to temper the heat slightly before it passes the grate and along to the gas exit tube .

Dave

The gas is cold by the time it reaches the grate. Once here there is nothing to heat it and the gas hose on this unit is never hot. Warm yes but not hot,

Edit: At least I think it is. I cant imagine the filter in the back is cooling it that much plus the obvious of the grate condition. More to learn yet

Really wow ! i would have thought the gas would have had to traveled through at least 16 inches of charcoal to lose the heat from the nozzle tip , on my first down draft attempt the gas was running through about 12 inches of charcoal and still coming out so hot i would need a cooler .

I think maybe i need to do a lot more experimenting and playing to get this right .

Yeah and Im not dripping the water in either Im pouring it in it is a solid stream. Yeah I honestly dont know either as I mentioned the updraft units the gas was very hot leaving the unit. The last unit I built like this one, I ran the smaller Predator 212 and the gas out hose was nearly at ambient temp. This 420 cc gets it a bit warmer, Id say 130 to 150 F.

Also that grate is long and naturally the gas is going take the least path of restriction. So I think it is constantly changing with condition of the fuel dropping down Plus clinkers, I run a lot of nails, need to clean the clinkers out almost every run. I should try to get the nails out better as its a pain.

Edit again: Well Im out of the pallets, so I guess that wont be an issue as Im now processing pine drops from the saw mill here. We will see if this fuel changes things

Well i cant wait to have a proper mess and see what i can get happening with my attempt , in the mean time i am busy making huge amounts of charcoal ahead of the burn ban that’s coming around the corner for us here in Aus

talk about nails and staples in the long packaging crates we have thousands to pull out and have just bought a electromagnet for them

I guess 2021 isnt too bad then, your still here!!! lol

We have just over an hour yet EST.

Yes we are still here and plan to keep going as long as we can even if it means staying out the way of crowds and food shopping while most people are asleep and me playing in a closed scrap yard due to the holidays break keeping Brian company and cleaning up the yard and making fuel all at the same time !

Hope you all have a very very prosperous and happy new year Matt after all your hard work .

Right on, Happy New Year Dave!!

I have a question for Kristijan about downdraft charcoal gasifiers.

How far down in the hopper did you use up your char without overheating the hopper? On my updraft gasifier when it got down to half full the temps came up really fast. I am thinking it would be different with a downdraft?

That is my experience, the gas out is also cooler. The hopper does not really get all that hot, pretty similar to a typical raw fueler.

Don, as long as there is charcoal above the glow zone the hopper stays preety much ambient. That is with a slight restriction in diameter between the firetube and the hopper

Dave; I had the problem of many nails in the wood I was making charcoal out of. On You tube they showed how to make a good electrical magnet out of an old micro wave. I picked up a micro wave at a second hand store for $8 US. It worked very good. I posted a video of me grinding charcoal and taking the metal out just before the bulk char went into my grinder. TomC

Hi all , Tom we have some fantastic magnets , i think they were for a rotary barrel magnet machine of some sorts they are very light but boy are they strong about 2 inches wide by 6 long fit in the hand real good , but cant beat the electro magnet for dropping them once there picked up , i did build a magnet last year from a old microwave , must see if i can find it again .

If i can just say something about a downdraft , i have asked before , i decided to turn my updraft into a downdraft last year after reading Kristijan had good results on his MB , i had mixed results them being that maybe i did not have enough distance between the air in and the gas out and it was not being converterted into good strong burnable gas it was also very very hot coming out of the gasifier , where as on a updraft it has a good amount of charcoal to pass through to lose that heat and to convert into burnable gas .

I will be trying again but this time i will build a purpose built downdraft from the start , while i am waiting to make a start i shall watch with interest and see how you guys get on as i am not so great a fabricator without dimension’s and photo’s i may as well learn from you experts .

Dave

Dave

How I came up with my distance is I measured the updraft versions after a full hopper burn. ( jet to top of the fuel that was left in there. I have 8 inches between my jet and the grate and also the pick up tube is at the back so it will draft diagonally not directly down. There is 12 inches from jet to the back side of the hopper.

( Tom C displayed a pretty accurate analysis of what I think is happening there. although his depiction is of the Flute design. On mine with the jet at the one end and the pickup tube at the other end, it also applies and is what I wanted on my design. )

Thanks Matt , i sort of did that with my attempt as well to get an idea of distance , but maybe because my container is so large in dia ( 45 gal drum ) unlike most that are around the 8 too 12 inch dia or wide , when mine runs low on fuel and when i am not around the engine will stop and on opening up the lid to refill it has a very steep angled amount of charcoal left up towards the top and the amount left is just under half a drum , so with a nozzle that sticks up about 8 inches from the bottom of the drum that leaves about 11 " of char covering the nozzle

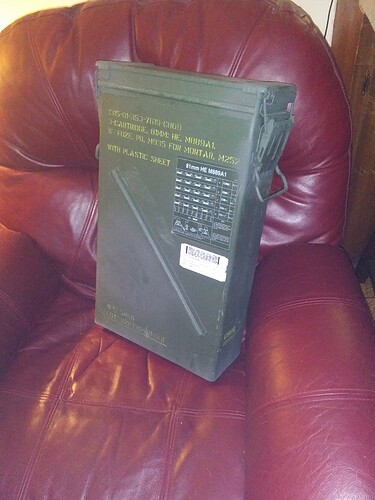

I have a fairly tall ammo box that I could tinker with. Would the holes be drilled on the narrow side or on the broad side of the box? I think I already know the answer but just wanted clarification.

Hello Cody.

What are the dimensions of the ammo box?

The Inside dimensions are 570mm tall, 130mm, 330mm