Huh thats gonna be a hard one… 130mm is just barely enaugh for engine grade charcoal to flow freely, not to mention the walls will burn trugh in minutes…

Hi Cody, I saw a ammo box like what you are showing but it was bigger. What Kristijan said is correct, It is to light of weight of metal. But with a larger box if you put ceramic wool on the sides and put stainless steel over the ceramic wool and secured it. It would hold the heat. Now how do I know this, is I have done it with another gasifer. In fact my next build is going to be what you have, but a bigger ammo box. Using a double flute will probably work better than the cross/down draft flow that I am using. I’m just waiting for the weather to break into the warm spring time. So I can start Building outside again.

In the WK Gasifier builds and other members builds we have used ammo boxes but as the main fire combustion burn area. It has just never being done yet. If you are planning on running it with a higher vacuum, then it will need some cross support brackets in the box. You will need to protect the seal in the box also. I use ceramic wool and welding blanket material for this in my ammo boxes. They are under my gasifer and are used as ash dump doors. I have metal tubing spacers cut and wedge in a the hatch cover doors with the ceramic wool to keep heat away and keep the boxes from collapsing under the vaccum pull in my gasifer. At times I will pull hard on my gasifer going down the road and it will be 30" plus of vaccum.

Bob

I was originally just going to make a flute updraft for smaller charcoal bits just as a sort of demo piece, and replace the rubber seal with muffler sealant worked into a gasket. Think it would still hold up in that case? The walls are about 3mm thick.

But based on your response I’m assuming the holes to hold the flutes would be drilled into the narrow sides so the flutes themselves would be at their longest?

Single flute, maybee. Dont worry about the seal too much. As long as there is enaugh fuel in the box, the gasifier lid will be cold.

Not nesseserly. But in any case, l think a single flure in the middle might be your best bet althugh still the walls will get super hot.

I’ll probably add a 2" pipe nipple at the lid so I can top it off quickly without fumbling the lid itself.

Would that be a charcoal only or be a downdraft? By the middle I’m imaging in the middle of the height, halfway down the box.

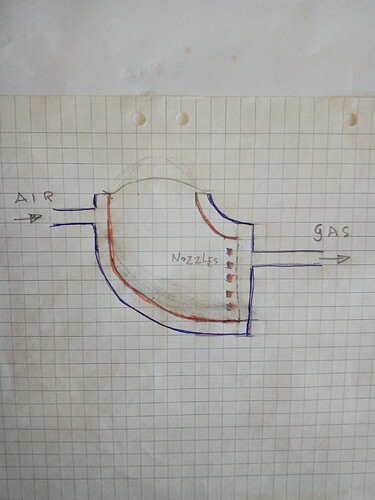

This is what I originally had planned, a single flute with holes pointing upwards air air coming in both sides, gas exiting at the top from one of the sides, maybe a perforated pipe to keep chunks from flying in. Fueled by some Gilmore spec charcoal only.

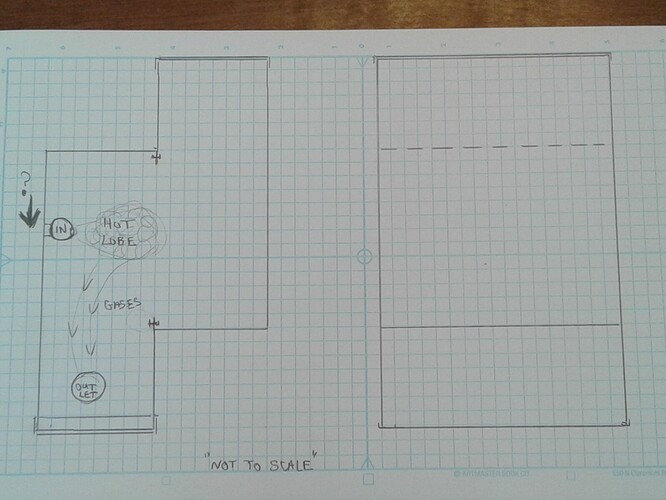

That circle in sharpie is the vague idea of where I’d put that flute if I wanted it to be a small piece charcoal only type gasifier.

Here is how I am trying to protect the walls of my “Ballistic Gasifier” which is the same size ammo box. I have not fired this one up yet

The big pipe is a piece of SS flex chimney liner (free scrap from a local company).

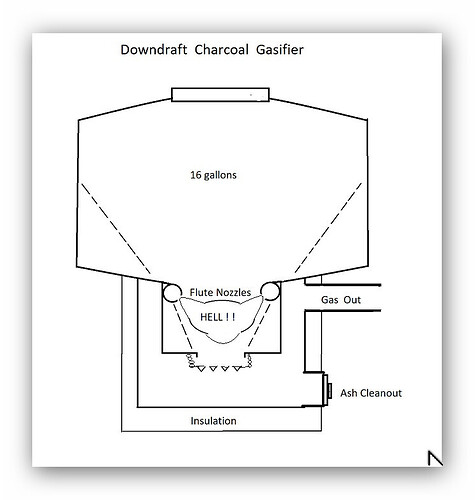

If you are planning on put a fill opening in the top , then turn your box up side down. Now you have a easy dump charcoal clean out. And this is where the flute pipe will be located. If it is going to be a updraft then the flute pipe will be about 6" from the bottom in the center of the box, holes point in the up direction. You need room for ash to accumulate when operating. If you are building a down draft your flute nozzle will need to be about 14" from the bottom. This has not been done yet to my knowledge. Kristijan made a drawing but I do not think he has built it yet. Pointing the flute holes at 90* is going to create a lot of heat , even if you have the flute to one side of the box pointing across to the other side. This is why I am saying you need ceramic wool and stainless steel protection in this area. My stainless steel shows some signs of heat warping. The mild steel it will burn right through. The heat lobe of the charcoal can get some where between 2000 and 3000 degrees Fahrenheit. This is why we need to keep it running at a cooler temperature.

With a wider box you will have charcoal protection on the side.

Maybe You could bolt 2 boxes together side by side with one up side down and the other right side up. Now you have a top hatch for filling and a bottom hatch for dumping. That just came to mind when I was writing this. The inside walls could be cut out first and holes drilled to be bolted together. If the boxes are staggered or off set by a foot or so and bolted together this would give you the space needed for the gases to travel down a out of the gasifer. I hope you don’t mind, I am just brain storming here right now, wrote it down.

Here is a quick drawing of what in my mind of a one flute down draft or it could be made a double flute charcoal gasifer. Or even a up draft charcoal gasifer. The question mark is where the nozzle flute would be placed according if it is up draft or down draft flow. Same with the outlet at the bottom or the top.

Bob

Has anyone tried making starlite as an insulator? Just spitballing ideas at this point. A YouTuber named NightHawkInLight shows how to make a rudimentary copy of the original insulation and tested it by covering his hand and hitting it with a blowtorch. I know gasifiers can get hotter than that but it’s worth trying.

I might take a note out of Bruce’s playbook and try my hand at that. I really like the idea of using the lid as an ash dump, it’s not very fast to open and not any easy way to make it a spring loaded lid incase of a detonation.

It will burn it up into a black crisp char mess, but you will get a little and I mean a little gases out of it. Not worth trying it. Use ceramic wool and shield it with stainless steel this works.

Bob

Cody, l think this will work best exactly how you described it! However there is no need to sacrifice valuable hopper size, the flute can be positioned at the werry bottom, or maybee just half an inch higher for easyer drilling.

Here, l think l wuld go with a slot instead of holes. Just cut a slot on top of the flute pipe with the thinest angle grinder disc somewhere around 150cm long. Later it can be adjusted by making it longer or wider, althugh wider is not what l wuld recomend… This will make a long and narrow glow zone and it might just stay cold enough without any insulstion to power a small engine.

like this ? …

I know the double flute would be ideal with a square reactor but would it be worthwhile with a cylindrical shaped one? I have a few already purged propane tanks and air compressor tanks that I could mess with. The only real challenge that I could see is drilling the holes just right for the flutes to go in without needing to fill gaps with welding. It would be vertically oriented the way I’m imagining it.

Hi Cody, just make it a circular pipe ring.

It will fit better in a propane tank.

Bob

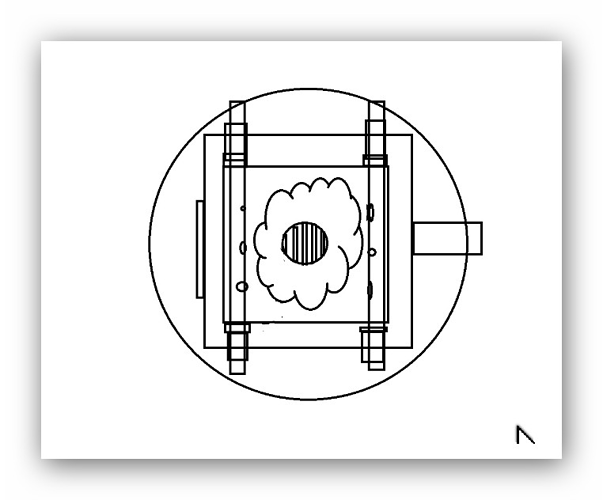

Top down view of the one I plan to make shows a round hopper tank with square beneath nozzles.

Side view

Gee I need to check my scrapyard and get some square tubing!

I plan to weld up 1/8th inch sheet stock. Not sure they make tubing that size anyway.