What size tubing are you talking about?

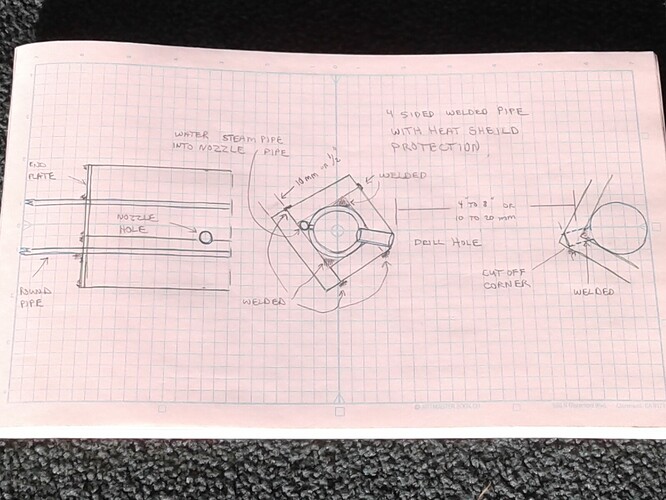

I have some 4.5" ID perpendicular measured, 6" ID diagonally measured square tubing with 1/4" thick walls. Probably too small though unless I used really small flutes, like a 1/2" ID iron pipe maybe.

I just need to build a quick ring roller and I’ll attempt a ring style instead.

So I started playing with a flute design as well. This is for a number of reason. An open jet / nozzle is difficult to add a spark arrestor. There has been times with a puff back will shoot ambers out the nozzle and across the yard. The flute design will reduce this if not eliminate this issue. A second issue is un even consumption where my hopper load is consumed more to the front where the nozzle is located. Then lastly is more thorough water to steam flashing.

So I attempted an arrangement where I had tiers pointing out each side. The water drip was getting sucked out the front tiers and there was not enough combustion to flash steam the fuel at the front became saturated with water. So that attempt failed.

So plug welded up one side and opened up the remaining holes and pointed them straight up. Now that worked great for a time. However once the hopper consumed down it got very HOT and the run ended pre mature compared to the simple open nozzle jet. However even though it did not consume as much fuel the run time was only short by 15 minutes. So my first observation is that it is running more efficiently.

With my open nozzle the gasifier does not get very hot only at the lower combustion stage. The gas hose is generally cold just slightly warm to the touch.

Not sure what I can do get rid of the heat, maybe add a second set of tiers like before but point them at 10 and 2 o’clock and then add a funnel above the jet to shield the heat from the upper portion of the hopper. I did try adding a shield directly above this top side flute arrangement that was a complete failure I could not even get it to flare.;

Thinking about this, what if I had the double flute like Bob is proposing here. However we add a third flute centered and just bellow the air feed flutes. This would be just for the water drip. No air feed into it; only water and it will be closed off other than its tiers. Have the jets so they are opposing each other as long as the process absorbs heat the air tiers will be protected.

I like it Matt, that idea would seem like it will work. Good thinking. I love when people build on other people’s ideas. That is what DOW site is all about.

Bob

Here I go again. Hang on to your seats we going on a investigation on what happened on the trip down to Argos Wood Gas Meet up 2019. And yes this will tie in to The Double Flute Charcoal Gasifer…

Has some of you remember Michael Gibb and I had a very interesting trip that year and I am still thanking Yehovah God for the Blessings He showed us in protection while traveling down and back home In Yeshua Name.

I am not going to go into all that happen because I can write a novel on the experiences of that trip driving on Dino fuel down there.

Wayne will recognize this, this is the air box muffer preheater that he built for the 92 Dakota truck (from the book) in 2012. It worked great nothing wrong with the built it was solid. But on the way down one of the mufflers started the leak exhaust into the air part of the box. This in turned preheat my metal pipe to my two blowers and flapper valve and everything melted down it even chared it black.

Thank God when it happened it was raining so hard that day that the rain was bouncing up off the highway and there was snow on the highway too.

Well I didn’t have any preheated air from the muffler at Argos, but the truck ran fine with out it. What I learned was to have a gate valve between the preheater and the blowers that can be closed manually for long trips running on dino fuel.

Now I just hate to throughout things away so let’s do something with it. Right.

Mufflers looked good until finally got the box all pulled apart.

Now I know it was not that big of a hole when I put in the junk pile.

And Wayne that was really put together well good job.

Well looke here Wayne, your preheater box is going to be a double flute charcoal gasifer.

No sense wasting all those hours of welding the box up and then just throw it away. No sir me use and reuse it and use it again.

With more projects going than I can shake a stick at.

Bob

Do you think steam introduction would really benefit a downdraft? I was planning on just adding some water to my coal before throwing it into the hopper.

Also worth another mention is that after the plastic pipes melted off, the HOT exhaust was blasting on the trucks plastic gas tank!

65 MPH air flow and lots of rain kept us from a flaming meltdown along the side of the road

Shuld act the same. However, adding water to the intake allso cools the nozzke more localy.

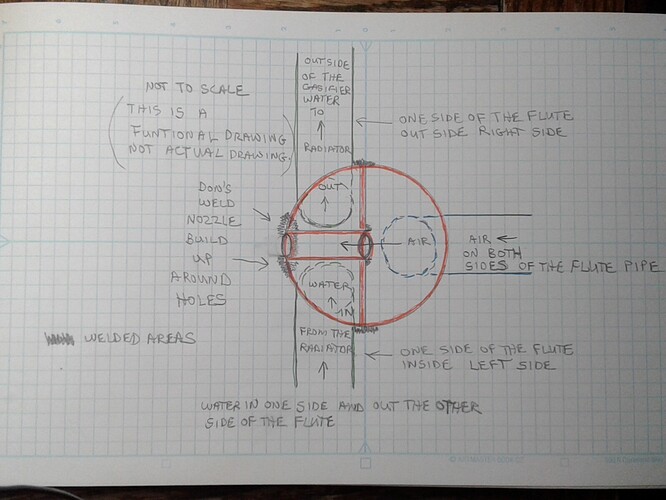

Hi Cody, if you look at my drawing you will see a small pipe on the opposite side of the nozzles opening water drip will enter the inside of the flutes if to much enters then it will run out like at shut down and I forget to turn the water drip off. I am kind following what Matt said he was doing. If the unit starts to get to hot it is a good way to cool the flutes down and keep driving, even if I am using water and charcoal mix. Remember you do not need to mix water into the charcoal if you are filling the hopper with wood. There is always plenty of extra water even if the wood is at 10% moisture content. I am hopping to beable to mix wood chips in my gasifer unit. This is why I will have a restriction opening above my grate. From the nozzles to the bottom of the gasifer it is 16" on my unit. I am doing what Kristijan did on his down draft. The ash will move to the side of the gasifer with the gas velocity in to a ash pit. Also I am planning on preheating my air.

Bob

Okay here a different cross view of the flute nozzle. Like I said heat is the enemy of metals so how about a water cooled nozzle flute. Heavy mass metal to carry the heat away. Passive circulating water through cooling radiators should do it creating steam to go into the nozzles for extra Hydrogen gases.

Again this is a functional drawing. When built, it will slide into the hopper and down into the firetube box area. The connections for air and water will be at the top of the hopper. Only the lower cooled water will come into the flutes pipes from bottom of the firetube box and make a pipe connection there. Ash clean out will access this connection. Cool water in and hot, hot water out up the pipes into the radiator coolers.

It is not shown but heat shielding will be used to protect the flutes between the nozzles holes. I thought Don’s idea is the simplest and most effective thing around the nozzles holes for build up the steel and the metal welds are harder then mild steel.

Water will move through the flutes and around the nozzles tubes keeping them cool. Not sure if it should be antifreeze cooling and just use water dripping like Matt is using, this would be a lot easier to do.

The fire box area will have ceramic wool and stainless steel for insulation and more insulation on the the out side. I have already tested this in my other charcoal gasifer and it works great.

Like Kristijan said the gasifer needs to be over built to handle the intense heat. With no welds failing. Keeping the heat out of the hopper from the fire box. Even the hot water pipe will help pre heat the air pipe coming into the top of the hopper and the pipes will be insulated from the hopper down to the flutes nozzles.

With the grate holding charcoal bed below the restriction opening, so only ash and fine charcoal will be swiped into the ash collection area.

The gases will move into the cooling tubes and filtering then to the engine for fuel.

I know it sounds so simple talking about it, but like all who have built gasifers it not. Unless it is a simple fire like Gary Gilmore has presented or @k_vanlooken has presented with their up draft gasifers. I am going to go the other way down draft way double flute.

I now have my retort, cross diagonal, down draft, and wood gasifer projects all going at the same time. In different stages of building. Which one will I finish first. Oh yes and the 92 Dakota truck work too on the blowers and check metal check valve or ball valve work, also my tachometer on the truck quit. Lots and lots of work to do in the world of gasification.

Bob

Bob, l think there is no need to overcomplicate things. Simple is always best. All l wanted to point out that a clasical up facing flute can forgive some things, like thinner wall or smaller diameter of the flute. But no such luxury can be taken here! The flute must be build right.

So what is right?

You can apply much of WK principles here; the ratio between the heat contact point at the nozzle vs heat dissipating area inside must be of a certain value. Im sure some person smarter thain me culd do the math on it but what l mean is that what people usualy forget is its the diameter of the flute that does exactly this! It is super important, in fact, just as important as thickness!

Let me put it this way. The diameter of the flute is what dissipates exess heat in tge incomeing air, but it is the thickness of the wall that allows the heat to be conducted efficiantly and trugh the entire surface!

Btw, lt is ecactly this reason why stainless or cast iron flutes wount do any good… too low heat conductivity!

So this sayd, l am comfident a sufficient dimension flute will have no problems lasting hundreds of hours. If problems do occur, and aditional cooling is neaded, the flute has a ability to contain a pool of water in it self. Might not be good for mobile application (splashing due to acceleration) but will work on stationary gasifier.

For mobile unites, Maxes water carbourator idea comes to mind. A spray of water in the intake will sufficiantly cool the flute plus adding the hydrogen.

So you are saying stick with the mass of steel wth the correct surface area diameter, with cool water spraying into it for cooling if needed and extra Hydrogen gases. Okay I will do it. Shoot Kristijan you are making this way to simple to build. We might have to call this the Kristijan Simple Down Draft Charcoal Gasifer (KSDDCG) thank you for your input on this build.

Bob

Why not leave nozzle holes pointing upwards in a downdraft gasifier? The reaction zone will still be drawn toward the center and down toward the exit grate. Would this allow protective slag to build up on the nozzles? Perhaps the sideways flame would cut/carve out the nozzle?

This is something we need to experiment with. Its why l adviced the first prototype haveing just frition sealed flutes so that they can be rotated.

My only fear of having them pointing up is hopper gases and steam passing by trugh any cold spots in the center. If the goal is to run on dry charcoal and add water in the flute l see no problem, but the way l think it is we are designing a multifuel overheat and tar proof gasifier.

To those not following KristijanL’s nozzles thinking . . . .

Reflect on this.

One nozzle system only have ONE to the root, outwards heat flowing pathway.

His double flute concept 4X’s this.

Two, then nozzle tubes; both ends supported = 4X for heat distributed out to reduce the nozzles heat metals killing.

And his insistence on tubing thickness mass gives the heat out flow capability.

Frankly I am puzzled by those saying to fin the nozzles inside hot ends? Huh!?

You want the least heating gain here. And a smooth round tube does this the best.

You’d fin area increase the outside external protruding ends if you were try to heat shed out.

Guys. Learn to think in heat flows in solids.

S.U.

I did just that, however at the end of the run the gasifier got extremely hot!! Plus its run was premature as it could not process a full hopper.

However, other than this, it worked extremely well, especially with the water drip. The water flowed in and then was able to boil down and was much easier to control.

Exactly this is why oppose SS in any portion of a gasifier it is terrible material for heat dissipation. SS hates being HOT. It will grow and stress until if fails.

On the single nozzle jet I use extreme pressure pipe couplings. these are hardened and thick couplings that surround this nozzle. That big coupling absorbs heat and protects that jet.

SS actually has a lower melting point than Mild Steel anyways.

Thanks Matt. Can you say a bit more about “extremely hot.” Were the sides hot because of less distance to nozzle or hot on top because the reaction was shooting up before heading down to the grate?

The lid of the unit I could not even touch with out getting a very bad burn. How that!! lol. It put off a very bad smell as well; like something is way to hot smell. haha.