Normally the lid is cold like ambient cold. The downdraft units are much like any other down draft gasifier.

I’m sorry if i missed it, but have you settled on the orientation that works best? 45*, 90*, 135*, 180*(straight down)?

I am trying a new design, with a double flute arrangement with a center evap tube for the water drip. The Evap tube will not have any air in it only for the water drip and it will be placed lower than the two flutes. Not sure what will be ideal orientation yet. I think straight across as the velocity will only go so far into the center and then get drawn down to this evap tube to heat it. On the Evap tube it will be straight up along with an additional vent leading to the intake of the two flutes.

See my latest post on my thread “Thrive Off Grid” CAD model renderings are there.

I had a little time today even with the wind was blowing on this beautiful Spring day. Close to 60° F / 15.6°C

I decided to have the hopper removable and also have insulation between it and the fire box.

It will bolt into place with side tightening bolts and nuts.

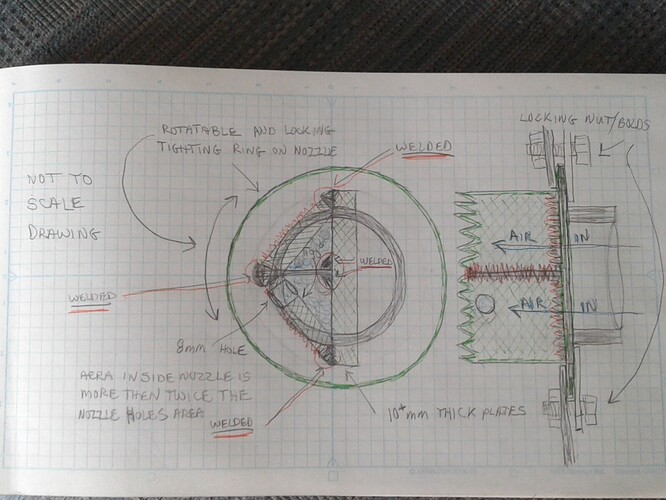

The opening on the side of the box will be where the nozzles will be placed, they will be removable also. There will be 2 air intakes for each nozzle. 2 of the intakes will be low for each nozzle so excessive water will run out if needed. This is the easiest way I could think of so the nozzles can be removed. The same kind of stove insulation will be used like on top for the hopper.

I might make the hatch door bigger on the nozzles not sure yet.

Bob

Bob, sounds like a plan! I love the detachable hopoer. Hope you manage to seal it good.

Also the 2 intakes idea is good. It will eliminate the problem a 1 side intake flute has, that is uneven combustion on each nozzle due to pressure difference over the flute. Its why l normaly advise to put progresively smaller nozzles in to compensate but you will eliminate the need!

Kristijan, my Subrau has a 2.5L engine. You said not the go to big on the nozzles sizing.

I will have 8 nozzles with 8mm holes drilled in them.

How far a part would think holes should be drilled. And how far a part should the flutes be from each other.

Bob

Certainly not too close. Its important that there is some “meat” between the nozzles to conduct heat away. I wuldnt worry too much thugh, just space them how it weels right.

As for distance, from the too of the head, the nozzles on the MB were around 7x7" and the gasifier was a tad small. But then again you can make it deeper to gain active volume, and l culdnt. Certainly a tight nozzle plane will have huge bennefits in tar cracking…

The Flat mass steel thick plates are easy to come by, this is a experimental flute design. The nozzles will able to rotate to change the nozzles projection into the charcoal. It is a triangular shape flute with a division in the middle in a openig at the closed end with the air entrance at one end and the air traveling to both ends of the flute so no air bounce or hammer with happen in the flute. The holes will be drilled to 8mm and a total of 2 flutes and 8 total nozzles holes. The area inside the triangular flute is more then twice the area space of the nozzle holes.

If the holes are to small I can drill them out.

Cold Water injection will be used also to help with cooling if needed and for extra Hydrogen gase production.

These flutes should be easy to build and less expensive then thick walled pipe build.

Bob

Well I had a mind fart, and I have changed my nozzles design. What a design change yup.

I keep listening to the input KISS.

Well looked hear I can use the muffler too. More and more of Wayne’s parts are going into this gasifer.

The small square pipe will divide the rectangle pipe make 2 passageway for the air to enter. It will not go to the end of the pipe which will allow the to pass by. The square pipe is where the water drip will enter at the blocked off end. The water vapor will fill the pipe and go out the open holes I drilled in It. Then back into the nozzles entrance pipe. Thanks @Matt for the idea.

With the nozzles flutes in place there should be around 5.5 " at the top and 6" at the bottom of the flutes when they are point slightly downward.

The nozzle holes drilled and dividers tubes installed.

Things are coming together out of this pile of junk I pulled out of the scrap pile. Never throw anything away. Unless you have to.

Bob

You are making great progress! I realy hope this works for you however l must be honest and admit l am sceptical. But you never know till you try!

Bob, there’s no going back now. Now you will have to prove Kristijan wrong

I admire your persistence. I’ve lost track on how many projects you’re running in parallell right now

Ha ha, JO, I have 7 projects all unfinished because I need something to finish it. And I refused to buy it. I am just waiting on finding the part I need, maybe I might find it tomorrow projects. The 2" black pipe I using for the intake came out of the field near by. The pipe is at least 75 years old and was in the ground in sand. They used it for irrigation, with lots of irrigation water valves attached. Old abandoned orchard land. Lots of junk just laying around no one wants.

Bob

Yes the thought of your square firetube and weld that fail did come to mind, lol. So I am double welding the box. Wayne welded the out side And I will weld the inside. And building a rectangular mass steel flute nozzles, oh come on Bob what next. Well…

Okay over the top of the nozzles will be Max Gasmans mass steel roof to protect the nozzles from white hot charcoal lobe. Will it work? We will find out. Each flute will weigh at about 8 to 10 pounds or 3.2 to 4.5 kilos of mass steel I haven’t finished them yet.

How much in monies have I spent on this project? Just my time, welding, grinding supplies. Everything else is free.

I would not be doing this if I had to buy the metal supplies.

Call me crazy, I will just take it as a compliment.

Bob

Your crazy comment brings to mind a quote from Adam Savage from the show myth busters

“I reject your reality and substitute my own!”

More work on the gasifer. Grinding things down and fitting the nozzles roof pieces to help protect the nozzle holes. I am just adding more steel mass to the flutes, they are getting heavier. With only 6" or 15.24 centimeters between the nozzles flutes the tars are not going to be able to make it pass the nozzles if I happen to add wood chips to the charcoal mix. The hopper will also have cooling condensation tubes on the outside to remove any excessive moisture/tars in the mix and will go into a condensation tank. With the vaccum exhaust added this unit should be a great gasifer. Yes I am a optimist in my thinking. It doesn’t make sense to be anything else to me.

Bob

Madness…

The sun don’t shine on the sea off madness and there is no wind to fill your sails.

But I rather be at sea with a mad man who has good intentions than the cannibals on dry land who call the shots these days…

Every piece of wood that was pruned that I can use is out of the orchard and piled next to the chunker.

Can’t see the chunker behind this pile.

The cat would keep watch on the new pile of cherry wood.

Well back to the double Flute build.

Bob

A might fine pile Bob!