No, not indefinitely; but yes you can charge it directly with heat or from a DC electrical source. If you did that with a TEG module it would immediately dim when heat is taken away.

that is quite a bit. it is interesting the voltage built up as well  Graphene isn’t supposed to be that good of a material for the thermoelectric effect, I was just surprised it worked that well with a low temperature differential.

Graphene isn’t supposed to be that good of a material for the thermoelectric effect, I was just surprised it worked that well with a low temperature differential.

how long will it produce the power after charging and how many times does it take a charge if it takes a charge for a year or longer it could be used for a battery if only a couple of times that would mean a long way to go. just wondering

It works best at lower temperatures. Graphite is a very good material with exception it can only take so much heat before turning to vapor. I found 450*f there seemed to be threshold where it would die out.

This is only experimental and just discovered. It is way to early to come to any conclusion of energy density, cycle life, etc. This will evolve from here into much more refined cells and design.

I have proposed a cell system that is thinking way outside the box. Instead of building a cell like a TEG where we attach directly to a heating application. We will not heat the cells at all. Because with this technology we can use a fluid electrolyte and can use this as a working fluid. We can heat the electrolyte instead of the cell, this solves heat transfer efficiency along with application adaption… Much easier to heat a fluid than adapting the modules as I think we will need a larger cell system to achieve any usable power.

So since we can print the active materials onto a cloth, we could do this very cheap. Size is not an issue, we could build cell stack the size of a refrigerator and still do this fairly cheap. Then we heat the electrolyte and pump through the cell stack. We would probably use flat plate heat exchangers as a very effective heat transfer system.

So basically what we really have is a heat activated battery / power system. I also suspect there is water cracking involved and it is processing like a fuel cell. If this holds true then we have a heat activated water fueled, fuel cell / battery system.

yes . I was wondering while reading your reply if there was a wet application part of the system. i thought i wrid before that it didnt work as well wen it dried out. Could have been wrong. but I like the idea of packing cells together then running a heated fluid through it very effective idea. also there would be hardly any wasted energy. and also could be any size.

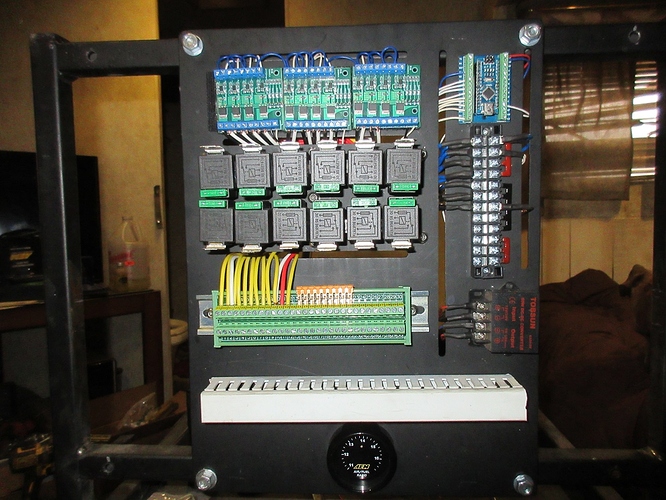

Next generation controls system is coming along. I think I am finally to a level where I can standardize this. So all machines will get this new controller including the stand alone gasifier plants. It has all revisions to work on the simpler unit all the way to auger fed system with integrated engine / generator management. So the touch screen along with auto ignition and flare lighting is now even standard on the simple gasifier units. About time they came out a MOSFET interface like this.

So Robert just came out with a new video on how to create zinc bromide electrolyte. So whats interesting is if you look up a zinc bromide battery, it is a battery made up of cell stacks like a fuel cell and you pump this electrolyte thru it. Sound familiar? If not go up a few threads and read my post about the proposed system I presented to Robert. Not sure if this is the direction he is going or not we will see.

sounds familiar maybe he is trying what you ask him to do and is trying it???zinc bromide batterys have been out for some time

Im hoping so, I dont think it is a coincidence. I think he is combining this into the thermo battery tech.

its possible maybe he read your message yesterday when you said you were going to make a pack of cells and run a warm fluid through them and is trying it. Check with him never hurts to ask.

Im in email contact with him directly

ha matt the battery you were working on wasnt zinc bromite but a carbon cell you dont add a metal plating solution to the plates to make them work. Zinc bromite cell are like a flash light battery but they are recharged by putting zinc back onto the plate then they can be discharged to near full discharge then recharged fully and vice versa with out harm. They need some matenance but you know. I dont think he is working on the same thing as you… could be wrong.

Maybe I dont know, however he is working on my cells. Im not sure you understand I am working with Robert directly.

I think what he is doing is after the cells are discharged, ((Cells are cold)) the electrolyte will be heated and then flow back into the cells recharging or reversing the electroplating.

oh okay sorry i just saw what you were saying

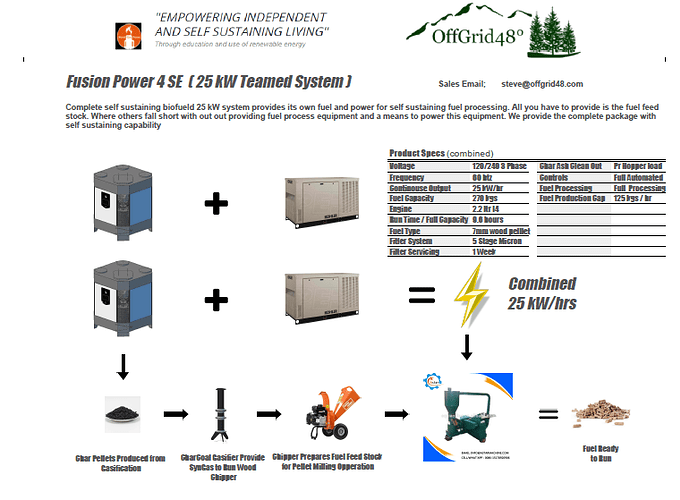

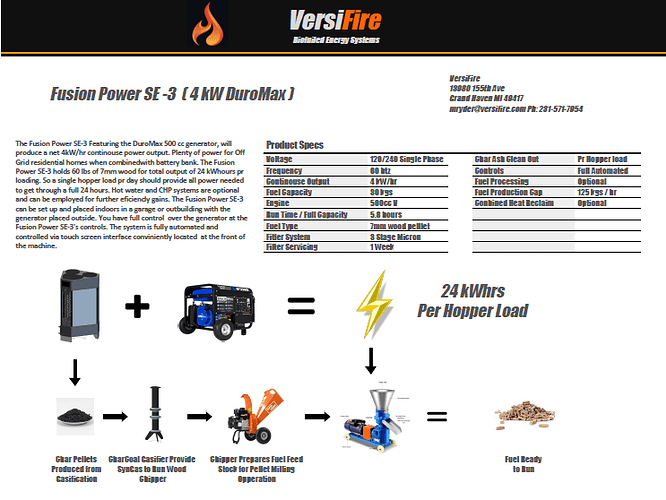

Three of the brand new Fusion Power Gens under construction. Ill be working on starting two more units this week. Those will be the Fusion Stand alone gasifier modules and then I need to make progress on the CNC machine build all at the same time!!.

So this machine will end this era of machine platform as I move on to the Fusion integrated stand alone version with Micron filter system. Its undergone a ton of evolution in its product run. It was the back bone of Vulcan Gasifier and later Thrive Energy Systems.

This one here will be the very last of the wheeled chassis versions. The pics above are hardly a snap shot of all the other iterations of what this plat form evolved into. There was the Evolution Gasifier plants and then the start of integration of full power units that would eventually turn into the integrated fully automated systems of today. Ive lost count but Im sure Ive built over 300 machines big and small shipped all over the world. I did all this in just 8 years!!

So new system complete with all processing equipment that includes a charcoal power chipper ran from char-pellets produced from the gasifier. The hammer mill and pellet press plug into the generator power. This DuroMax 500 cc genny should net around 4 kW max output with a 5.8 hour run time pr hopper load. So if using a battery system a single hopper should last a full 24 hours.

patent for Edison nickle iron battery expired . This battery was used extensively in mining and rail .

split between building a device and making claim of intellectual property . that this device was built from findings going back to 17 Th century a jar two electrode connected to wires electrolyte .

New patent is claimed for Edison nickel iron battery as producer of hydrogen gas .

Question is there not a design for electrolysis of water , sea water , lye that is more efficient and proceeds any junk patent ? I was thinking about salt bridge