Could be it’s just stuck.

I rely on natural flow most of the time and don’t use the radiator pump much. When I do decide to use it it’s often stuck. A tap or two with the hammer on the housing usually helps. With a screwdriver between the housing and your ear you can hear if it’s spinning or not.

Hi Jo , no its spinning up ok , if it stops then i would know within 15 mins as the water in the expansion circulating part of the system would start to boil , and so it needs at least 1 pump running to aid circulation of the expansion system .

I know that for sure as when i first started using this unit i over fed the fire with only the 1 pump running and it got to boiling point and i could hear the impeller squealing inside the pump , i called the heating guy at the time and got him back to check and he said no its all good ,even though i told him i could hear the pump he would not replace it , he called the supplier’s of the pump to check the max temp running limits he was waiting to hear back from them but said it was fine when i next spoke to him .

Dave

I have a very long run with one pump outside one pump inside for flow to the empyre system optimizer , the temperature controlled bypass valve in loop-back . If this valve allows it there is another pump for flow to heat exchangers . I added thermostat switch to this pump to keep house from getting to hot . then inside boiler has circulation pump that runs at all times . I like to keep the rust circulating .

To live, the boiler must work well with a load of more than 50%, otherwise it cooks tar and wood gases escape through the chimney, so it is almost necessary to have a storage tank on the system. The boiler is like an engine, the pump must push water on all heating surfaces unhindered, and the thermostatic valve ensures that the return is adequately heated (60 ° C). That’s what you Henry have done, only the saver is missing.

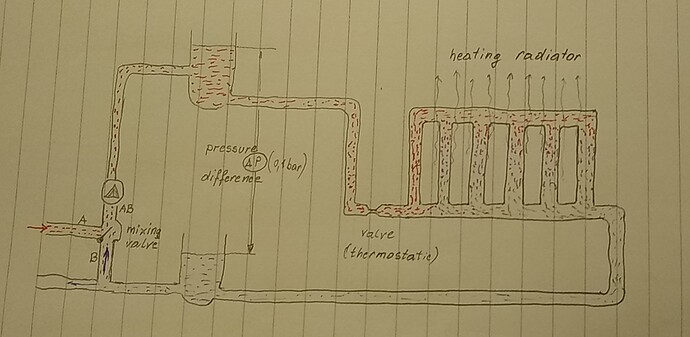

If the radiators above are hot below but cold means, this indicates a slow flow of water. This is a phenomenon when the thermostatic valves shut off the flow because the room is heated and there is nothing wrong, but if the room is cold and the valves are open, the cause must be sought in the pump and valve for preparation, or perhaps in the presetting for balancing thermostatic valves .If you have a three-way mixing valve, check whether the pump is installed on the MIX or AB branch (this branch can never be closed), check whether there is any bay-pass on the system where hot water is circulating, …

I’m not really seeing how the panels work. Is the tubing just at the top of the panel and then air is convected up though the rest of the panel? The tubing looks very small. If my well was supplying water to that system it would start to plug up after a year with calcium. Also I’m completely unaware of measuring heat in KW. First time I’ve ever seen it is on this site. I know this is no help. Just curious about what I’m seeing.

Haha, I was unaware of BTUs until I joined DOW ![]()

1 BTU/hr = 0.3 W

Dave, steam in the pump? Is it connected on the hot side? Always put it on the cold side, for this reason and on closed systems to avoid the high temp and give the pump a longer life. So, pump should always push, not suck through the boiler. Open system is safer then closed system, but you can run into strange things. It sounds that there is no flow, sucking in air from expansion vessel? Automatic air outlets can suck in air in open systems and so on. Or a missing air out can cause blocade.

Biggest disadvantage of an open system is the oxigen sucked in every time it cools down.

Bravo Joep, for understanding hydraulics the basic principle is, “water is not a rope to be easily pulled, but we can just push it”

Thanks, and that is where my knowledge ends. A few basics, nothing more. I am impressed with your system. Totally diff from mine. Our buffer has a central function for woodboiler, pelletboiler, heatpump ( not connected yet) and CHP. Last one is becoming a real long story. Central buffer is needed for the woodboiler. Filled that one for the thirt time yesterday, took a look at Domotisz system and quickly took out a few blocks. End of the evening got a 100 C on top and 90 at the bottom. Safety cooling is not connected of course. No need!!!

Thanks for taking an interest guys , you talk about so many things so i can answer a few of them so we both know what i am trying to describe

Tom i find it strange that you don’t come across common hydronic radiators in this day and age but never mind , i am no expert but hot water enters and flows through a horizontal copper pipe that has a series of vertical copper pipe attached and they go onto another horizontal pipe on the top, all the water is then carried to the opposite end of the feed and down and out the rad this 20 sec video explains it much better than me .

Hi Joep , as far as i can tell there is no steam at all in my system and as it is a open vented and air rises air and steam should move through the pipe work freely and end up in the expansion tank i would have thought the system was built by a qualified plumber and yes both pumps are on the cold return flow to the fire and tank and it takes the hot water from the top pipe that comes out of the back of the fire that then goes into a T that vents up to the expansion tank and the other side goes down to the pump and on to the manifold then rads .

I have no idea how oxygen is sucked into my system when it cools down and why that would create my problem .

Hi Tone all you have said is correct my water must reach 40 degs c in the tank before it will switch on the pump to help circulate the water around the expansion tank and to get the flu hot enough to stop the build up of creosote in the chimney and then when the flow valve in the basement detects a temp of around 60 degs it then opens up allowing water to travel along to the radiators and making a fully open circuit then the other pump is activated by a central thermostat rather than individual ones on each radiator .

The more i look at it now i am convinced the lockshield valves have not been set to restrict the flow back to the fire and so is not heating up the whole panel .

Dave

I don’t think that kind of radiator is common in the states or at least not when I quit the house building business ten years ago Dave… All hot water heat I dealt with was baseboard, finned pipe or radiant in-floor or towards the end a couple in wall. It is a nice clean looking set up. In my experience all air that could get in a system is vented as it goes back to the storage tank. I don’t understand people like your installer. When I built something for someone, if there was a problem we made it right ASAP. The old golden rule.

Hi Dave, I think the animation in the clip is a bit misleading, I imagine the performance kind of like this …

Hi Tone , your probably right i was just trying to show Tom how these types of radiators work , on your drawing on the return out of the radiator is where i have just found my Lockshield valve i have given it just a slight turn down and i can see a balancing result straight away look

I wish i had done a before and after photo’s now to show you just how large the temp diff was .

Dave

I have installed Danfoss FJVR (return limiters) on my radiators instead of the lower shut-off valves, they allow automatic balancing of the system, and they are generally good when heated with a heat pump (low return temperature)

Tom I think you are correct. I also noticed that those radiators are located on interior walls and beside the bed putting heat where people are more likely to be.

I remember reading that back in the 60s and 70s Americans switched to a different theory of heating. We switched from having heat in the center of the home like with the old fireplaces putting heat near the chimney to central heating with heat near all the points where cold air leaks into the home. The idea being that you put the heat where the cold is to cut the drafts or warm them up. I have to say it is a theory that works when I fire up my big hot air furnace the farm house from 1901 will stabilize regardless of how cold it is outside. I am willing to bet that there is a nice rosy glow around the entire house of hot air leaving though.

When I was looking into building homes around 2000 this is one of the things I struggled with. I wanted to do high thermal mass heating systems with modern tight construction. The person I was looking to start the company with argued that people won’t accept something so radical different. I think he might be correct. I had a house built in the 90s with modern windows and it was tight. But yet the open concept house had the same old theory of heat around the perimeter of the home to heat the leaking air. Ofcourse since the house had a open first floor to a second floor loft that totally missed the point the cold came from the center of the house not the outside as air moved between floors. All that to say I suspect this is a cultural difference but that homes designed with the radiators in the middle and tight outside walls actually feel warmer with less heat.

I remember the “octopus” furnaces in basements were common in the first half of the 1900’s. These had large 12 inch pipes coming out of the “bonnet” with short runs to large registers in walls and sometimes floors in the center of the house and the return air came from floor registers at the outside walls. These circulated the air by gravity flow and did not need a blower. The houses had mostly 9 foot high ceilings to even out the layers of heat which would be too intense with lower ceilings. Wood and coal were the main fuels until natural gas was available.

We got ours later and the hot air is sent to the outside with a blower. The one in the farm house is from the early 70s. Still has the orginal furnace but it wasn’t used alot combo wood oil.

Ha, just when you think you know it all…

Right before I went to bed last night I remember reading TomH mentioning cultural differences (but I don’t seem to find it now). Funny how it applies to even heating and plumbing

Anyway, I’m starting to think he’s right.

Up here I’ve never come across Tone’s “pressure diff setup”, Dave’s “bottom in” radiators or American “center of the house” positioned radiators.

Of course pre central heating and plumbing, stoves and furnaces were centered close to the chimney, but ever since radiators are positioned under the windows and fed at the top. It prevents cold floors (cool air dropping from the windows). Also, no more condensation on the lower part of the windows.

So, why is this difference? Maybe because in the Nordic countries we never wear shoes indoors. It would be considered quite rude if you walk into someones home without taking them off. Anyones wife would stare at you and start wiping mud or melting snow up.

I remember first time entering a forign home - in England. Front door straight into the livingroom with broadloom carpet. No vestibule for undressing ???

Broadloom even in the bathroom - around the toilet and everything ???  At my young age I was shocked. Also, that was the first time I ever came across natural gas for heating, apart from camping gear of course. You live and you learn.

At my young age I was shocked. Also, that was the first time I ever came across natural gas for heating, apart from camping gear of course. You live and you learn.

I’ve had some experience with those old furnaces Don. Mostly trying to get rid of them since all the ductwork was wrapped with asbestos sheets that were pasted on and there for good. Unbelievable the hoops you had to jump through to dispose of it. I still have certain grids in the local landfill with my name listed because I disposed of asbestos. They started doing the same thing with lead based paint scrap. That’s when I quit remodeling.

Found something saying there are state sponsored rebates for wood pellet boiler system . This was Vermont and New York State .

https://www.efficiencyvermont.com/rebates/list/central-wood-pellet-furnaces-boilers-business

I never got rebate . Not accepting applications , years funds have bee dispersed .