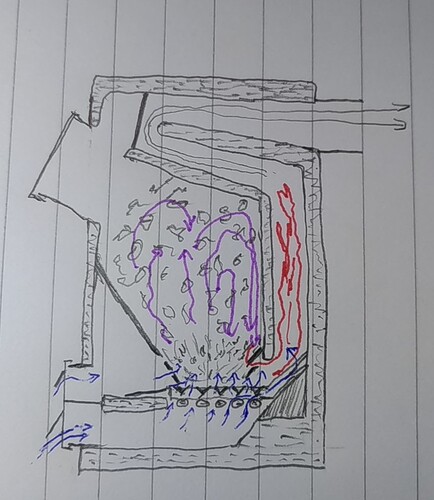

This winter I am heating the house on wood chips because I was bothered by smoke, I tried to remodel the boiler so that there is practically no smoke. The boiler has a lower side combustion and when I poured the wood chips, there was not enough air in the back, which I solved with an additional grille with four integrated air ducts, at the same time this grille allows higher temperatures in the glowing lower part to reduce gases. I added two more sloping panels in the front so that the reduction zone is shifted towards the flue. It works great, I am satisfied and grateful to everyone on this furum who explains the theories of grinding and to Kristjan for the idea of angular profiles for making the grate.

I like pictures/sketches. Is that a “boiler” with water or just air heat? TomC

GREAT!!! Looks like Spaceship Enterprise engine room. Where is your WARP core?

Tone, do you remember professor Baltazar?  Lot’s of pumps and piping.

Lot’s of pumps and piping.

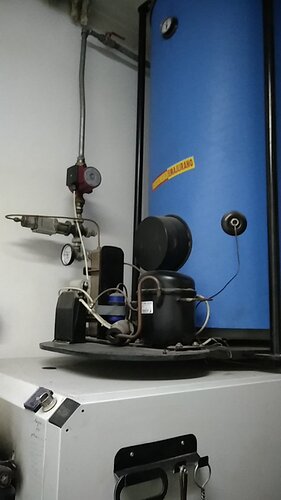

What’s the fridge compressor for?

Tone; I suggest you give the first few molecules of water that are to go through the system, a road map, to find their way TomC

Haha, yeah, that is quite a setup. Does your wife understand what all the valves do?

Well, I didn’t say I dont have unfinished projects. Actually to many.

I dont know Tom I have so many projects it seems like non of them get finished. Not that that has stopped me from looking for more. But I do find it overwhelming at times. I often have to forget about some of them just to not be so overwhelmed that nothing gets done.

This last year seemed to side track me with something new everytime I thought I would finish something. But the barn with the chickens and pigs is much nicer even if it wasn’t on the project list before the year started.

No, no problems at all. The only thing is to make sure the plate over the brakes is connected, so left and right break the same time if you are driving on the road

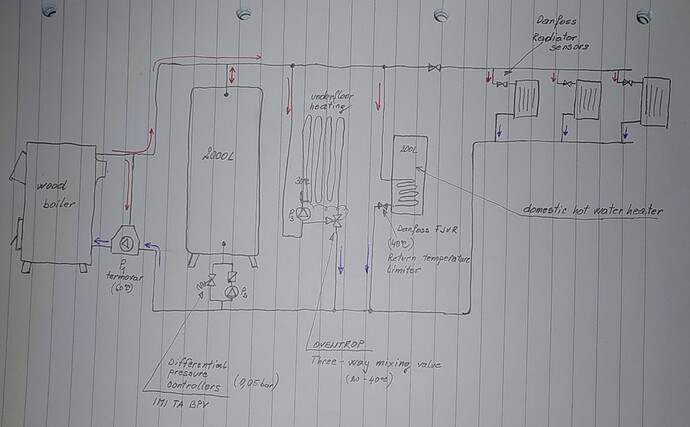

Hello Carl, my wife likes to burn in the boiler, and she doesn’t need to close the valves, she just presses the button when she fires and that’s it, I’ll draw a sketch of the binding and you’ll see that it’s a simple system.

Nice schema, @Tone. Very informative.

Do you run your wood boiler in full blow until this big reservoir is hot at mac temp and then shut the boiler of until hot water in main tank is exhausted? Or you keep it as hot reserve all the time?

Now that it is cold, I heat up in the evening, when the heat accumulator is emptied from the previous day, the boiler operates for 3 _ 4 hours, consumers around the house have priority, but when the boiler power exceeds the consumption, the differential pressure between supply and return rises above 0.05 bar. let hot water into the tank …

Very interesting. Unconventional, is that the right word?

Domestic hot water too. Why is the return limited to 40? To make sure temp in boiler is higher then 40?

I have valve that prevents flow below 145 f but seems to stay open down to 125 f . What I had to worry about was boiling water suddenly going into system . I shut valve till system cooled down . Happened running motor with gas from boiler .

@Tone interesting setup you have there. I do like the mixing valve on the return to the boiler to avoid shocking it. When I setup my Tarm wood boiler that was something I forgot and on a cold startup I had to be careful or the bulk storage tank in my case 700 gallons would quench the wood boiler and the fire would not burn clean.

@KKubu the Tarm wood gasification boiler manuals where clear that they wanted you to burn the full load of wood both meeting the heating loads and heating the thermal storage tank then wait till the tank was cooled down and able to take another load of wood worth of heat before reloading. I ran mine like that for about a decade I guess i would fill the wood boiler twice a day in the bulk of the winter a third time when it got really cold but that wasn’t often. My best friend had the same wood boiler without a storage tank and he burned about twice as much wood as i did for almost an identical thermal load. Our two homes where very close in location and size plus age. So my advice would be to design the thermal storage to match the load capacity of the the wood boiler and run out one load of wood full burn into storage. My tank was a non pressurized tank with one set of coils for the wood boiler and a second set for the Domestic Hot Water. That worked perfectly for my with the exception that in the summer the tarm wood boiler didn’t draft well to heat the storage tank back up the one time I needed to and would overheat the house with waste heat so I ended up heating the 700 gallons once with my oil furnace which was the backup each summer. But that didn’t burn much oil anyway so it wasn’t a huge deal to me.

I did really like that system it was shockingly efficient. But I think my next system at the farm will actually be a subfloor radiant heating system because they work at much lower water temperatures. I think I can win with a solar PV system and generator backup to power the system when the PV comes up short. Those Tarm wood gasification boilers have gotten crazy expensive and the same money will go a long ways in the solar system today. As much as I miss the tarm I think a wood gasification tractor and PTO generator might be a much better long term solution for me.

Code here is to have a dump zone and dump valve that kicks in below boiling so it is fail safe to avoid your boiler becoming a steam bomb.