The best safety feature I have seen on a tool is the capacitive touch table saw that stops immediately if your finger hits it.

Yes, that is really impressive, i’ve seen youtube videos when they demonstrates it with a hot dog, i wonder how it works with slightly moist wood though?

Yes. The show with the sausage is fine but I wouldnt trust it with my fingers ![]()

Next step is video. If your hands are in a forbidden area, it stops.

I sure wish the table router I was using had such a safety.

Turned my fingers into hamburger meat back in 2013

Nobody ever told me to not use a Fence with a chamfering bit. I just use hand tools for woodworking now, I get nervous around a lot of power tools.

I think my name should be legally changed to Crispy “Lucky” Critter

I would suggest getting one of these. I have a friend that swears by his, and looking at your finger, while it seems expensive is much cheaper then an ER trip.

Tool deals of the week.

A hand held gas detector at the start and an 88 dollar Yes stick welder at the end.

I wanted to report on this Milwaukee 12V air compressor. I use the 12V Milwaukee tool line and this compressor was gifted to me a while back. I thought it was pretty much a toy and it’s just been sitting unboxed for some months now. Yesterday I had to move an old tractor that’s been sitting for years and the front tires were completely empty of air. I put this thing on them and it pumped a tire to 25 psi in about a minute and a half. Both tires on about half a charge on a 2 AH battery. I have a 12V compressor you plug into a vehicle and this this was at least three times faster. Even being a major cheapskate, I’d probably pay my own money for this thing.

Ya my buddy keeps one in every vehicle he has for emergencys, and we use it for all sorts of stuff. Wheel barrow tires, truck tires, kids footballs, airbags on a pickup ect. They aint bad at all!

Dad got one for christmas a few years back and Swears by it. Takes it on all road trips. I have used it and i like how compact it is… my only problem is its M12 amd all my stuff is M18. I have looked at the M18 compressor and it looks promising as well although quite a bit biger foot print. Wish they made an adapter to run the M12 with the M18 battery.

a question to the practicals here…is the heatresistant silicon - for glueing gasket wrops - the same stuff what is used for motor sealing ?

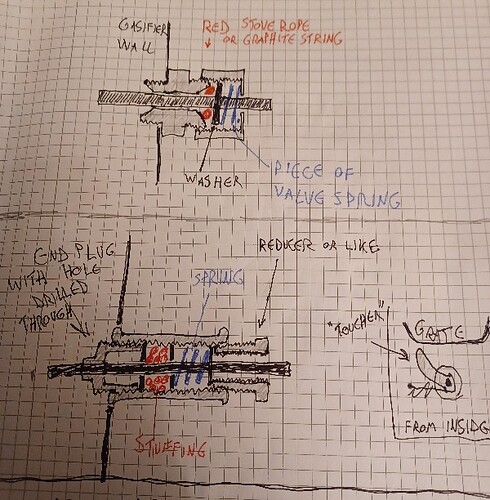

and a idea…for selfmade stuffing boxes , like that on my cooking gasifier, with stove wrop fibers as gasket material, could be helpfull introduce in the box a disc and a spring to keep permanent pressure on the thightening material, and so avoid hot leaks…for example shakers for grates…

ciao giorgio

Hi Giorgio, i’ve used stove rope in stuffing boxes (without silicone) works well, never noticed any leaks. Both “dry” and with some high temp sealing compound or graphite powder “dissolved” in some oil or soap.

Recomends some of the lubrication options.

I’ve also used a spring type sealing as you described, but with a “threaded sleeve” so there is possibility to adjust/increase the spring tension (should be very stiff tension), as it looses by time, due to temperature changes/ thermal stress.

So Goran, do you make the stuffing box so you can make adjustment for maintance? Do you have a picture of this? I want to make a mechcanical rod shaker on my present build.

Bob

Hi Bob, i’ve made some drawings for you, some “types” i tested, made of mostly different pipe fittings and stuff, i’ve used stove rope and graphite string (available for pumps with stuffing boxes)

Observe these are only “rotating motion” types, but that often works well.

Old type “shake around” types i’ve tried also, but these need a big metal ball with a hole through, and that is a hard part to find (drilling through a ball bearing ball is horrible work)

This are not exact drawings, more to give ideas, only ones building imagination sets the limits ![]()

Please feel free to ask, or demand better sketches

Forgot to mention: some of the compression fittings (if thats they are called) needs to be drilled or grinded through, to get a same diameter hole all through.

on my mower gasifier i have a shaker through a stuffing box that moves forward and back and a bit rotation of course…the end of the rod is bended upwards where it grips in the grate…so it not needs a ball, when i have understand you right…

When I was young we had a well pump that used a stuffing box like Göran shows.It had to be maintained every month, but it worked very well.

Rindert

WOW Goran, thank you for all the drawings. This is great. I will study each one.

Bob

Handheld Laser Welding and Cleaning Systems for Manual Welding Applications | IPG Photonics

I think I saw this a couple years ago. I haven't seen anyone on youtube use it. I think one of you rich guys should buy it and report.I actually got a few hits when I searched lightweld on youtube.