Hope you make a new thread for this, I would also like to make a small wood generator for my electric unit but don’t know how to avoid hanging etc.

Wow Tone, a lawnmower dragster ![]()

![]()

And what the rest said, cant wait to see the next step

I believe I’d fabricate some kind of Sulky to hook to that thing and let it pull me around. Course I’m old and lazy.

Hi Tone,

I will be following your mixer developments for this big single cylinder with much interest.

You did some unique things on your propane mixers . . . I still puzzle about.

You are correct that the reverse intake pulsations are severe and disturbing to steady mixing. The woodgas and air wants to layer.

Most “better” ideas I’ve tried failed to produce better results than just crude mixing inside of the factory air filter boxes, with the filters removed. The boxes then sealed up.

Be careful of too much added weight mass in your creations onto the original carburetor two-bolts/two-studs. Use aluminum and resin plastics here as much as you can.

Some of my direct bolted onto the cylinder head creations would later joints and welds crack from the vibration.

And remote mounting of the mixer body connected to the engine by flex hose often results in slow response and even worse mixture layering stacking up. Lenth tuning pulsations favors one RPM range at the expense of other RPMs.

Single cylinder engines vary a lot on their individual intake pulsation characteristics. So the surprise is what works for one engine type will not work well on another type.

Regards

Steve Unruh

Steve, do you think a sort of cyclone with the air mixer valve added would work? I haven’t seen anything for that yet. It would produce a drag on the system but perhaps a flows oversized cyclone would account for that. This would be a way from the carb and connect via hose to prevent weight stress. That final cyclone may also help drop soot one last time before the carburetor.

Or maybe a mixing chamber before the hosing going to the carburetor. Like many using their truck air cleaners as a mixing bowl.

I think a small green propane bottle or something in that Liter size range could work, maybe.

Edit: It seems that the WW2 style of air mixing makes a lot of sense. Flows demand on different fluids. Either Air mandated or Gas mandated. Peep the pictures in the link.

Briggs and Stratton used to twist a flat ribbon of steel into an air mixer for reasons that were never clear to me.

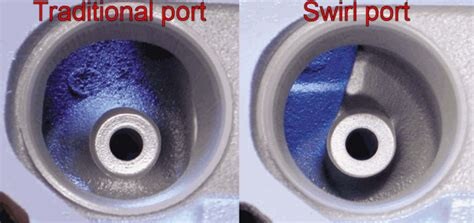

Swirl ports were an 80s solution to better air mixing.

Pretty sure I posted pictures of some heads i modified years ago with some swirl worked into the ports.

I don’t have them anymore because that computer died.

What I do know is that a good tight quench makes up for a lot of things inside the engine.

One of the reasons I suggest people build small block clones with the Z4M piston and the 14CC head.

Compression and some very good turbulence and some quench effects.

Small valves also.

Small valves mean higher velocity.

If you have that option the smaller valves on the 18cc honda head for example will promote better mixing by simple virtue of higher runner velocity in a 208 or 212 motor

Textures on your intake and and port will change the speed gasses flow and you can cause turbulence.

This is not what people tell you to do when you hot rod an engine but in this case you want to cause gas to tumble fast on the outside of one place and cling and move slower on say the inside of a turn.

This will cause gases to spin in the intake system and spin faster with more turbulence as they enter the combustion chamber

I dont think l ever shared my accidental discovery here, thanks for reminding.

I have found single cyl (specialy a slow one like those) are a whole different animal.

First, my thrusty towel sack filter has proven useless on my BCS. The pulses shake the cake off and trugh the towel.

Second, l found something interesting. I lost the filter lid (sewer pipe cap) so l improvised and streched a tractor inner tire over the filter. Not only it worked as a lid, but it also worked as a expansion vessel, smoothing out pressure spikes when the motor pulsated. And lm quite sure this aided to power some (impossible to tell on a mower) because at the end of intake, the gases in the sistem still have inertia. That inflated the membrane. At the begining pf the next intake stroke, the engine has some gas alredy prepared, it doesent need to overcome the gas inertia of the whole sistem. I will be trying this out some more…

To get a pipe feeding gas into an engine to resonate you need about 6 to 8 feet of runner length for a first or secodn pulse to move back and forth. ( above 1800 rpm quite easy to have happen )

In some cases this is great it makes for more power.

In other cases it can cause problems

an easy fix for that is keep your pipes as short as possible and make you gas cleaning unit as big as possible ( internal volume )

Not so easy when you dow, but more of a consideration for stationary

I think there was another thread from a long time ago where I show a 100l grease drum I used with some cotton fabric filters I made from the wife’s old cotton bed sheets.

It was not a very good filter media because they were worn out.

To prove the resonant pipe single bounce could be done for a stationary engine I built a Petteroid intake with a 1 inch PVC conduit that was about 12 feet long tuned to 1500 rpm.

It worked but it did not translate into any useful power gains.

If you held a piece of paper near it you could see the pulse…

Interesting multiple approached to the same problem Beast - single cylinder 4-stroke engines.

Your’s Kristijan (rediscovering the Miller Cycle) has the most possibility of being compact, tunable and practical use with woodgas I think.

First All really, really study the Beast of a problem. Watch these many super slow motion Project Farm videos for the Intake and Crankcase pulsations:

Open up Playlists.

then work your way down thru Alternative Fuels 22 videos;

E85 vs Gasoline 8 videos

Fuel Additives 19 videos

Engine Oil additives 16 videos

Engine Oil Alternatives 13 videos

Destructive Engine testing 16 videos

Time line bar forward thru each video to see jest the engine running portions.

Pay attention to the seen pulsations seen thru the carburetors and crankcase out (another pulsating energy source). See his temperature readings on the cylinder head, engine exhaust too.

A single cylinder work engine does not have to ticky-ticky-tick over at 300-500 stand-by idle.

Be harmed not able to splash oil and hot-pockets cool itself doing this.

So figure a minimum of 1200-1500 RPM idle. Best working RPM of 2400-2800 RPM.

3000 RPM you are pushing it IMHO. 3600 RPM is engine stretching into Life shortening any way you want to view it.

Regards

Steve Unruh

Steve, here we use these old Itaijan engines (50 years old), which have suffered a lot in this era and are still competitive with all replacement engines in this category. I mean Acme and Lombardina, with Acme engines the main shaft is set on roller bearings and also the center on a needle bearing, these engines work very well at low revolutions and I have never heard of any of them stalling due to too low revolutions, higher revolutions are more damaging. Lombardini has a sliding bearing in the middle and is an OHV engine, the diameter of the piston is 88mm, and the stroke is 80mm (Acme also has a similar one), this engine works better at higher revolutions and runs very easily. Both engines have quite long pistons and also long rods, which can be seen by the height of the engine, they have all the good characteristics for operation on wood gas, I felt this during testing, it just needs a good gas mixer and a rigid connecting pipe for gas. As I already wrote, I think I could reach 5 kW of power at 2000 rpm per wood, it also makes me curious.

Just finding this discussion interesting, this is something i’ve experimented with years ago (not in woogas purpose), found it in some old book, kind of a “pulse damper” maybe something to implement in various single cyl builds?

And an interesting fact: the old Imbert’s seemed to work better when feeding big, slow running, single cylinders, like converted hot-bulb’s. My theories is it gives the gasifier short “recovery” periods during the pulses, something like the early 1900s coal gasifiers and water-gas gasifiers. There is documention how one could see the pulses through the nozzle, as the glow flickered in step with the pulses.

Any thoughts?

This is very interesting. @gasman , Max talked about a resonator tube. I tried on my gasifier it had to do with frequinces. It was on my V-8 engine and was trying to get my engine to stop back firing, it turn out I had a intake leak causing the problem. I did notice a diffence but it still back fired after pulling on a hard hill pull. Fixed the the leak and have had no problems. I removed the tube because it was not needed any more. But it had a design like that baffle in it.

Bob

Hi Goren,

Many of the DYI small woodgasifiers I’ve operated had a way to view into the heart of the Beast.

When on stationary units the single cylinder engine was very closely installed to the gasifier I also saw the char glow beat to the engine’s intake pulse.

Of course, it depended on the amount of filtering steps and cooling racks the builder had installed.

I am sure this helped to clear the char chunks of surface ash exposed.

Risky, risky to use this phenomena though . . . warming up system tars. Re-fueling cooling down tars.

Yes Tone. North America as Wallace said we once had cast iron small single engines like this too. Tall blocks. Long rods. All replaceable bearings. Special in crankcase oil holding sub-troughs for slow speed operating. None new now for 40 years.

My own thoughts going forwards for my electrical generators is to try and relieve the engine of sucking the gasifier and filter train. Instead supply the woodgas slightly pressurized delivered to the engine like done with propane and natural gas to the engine.

The woodgas; intake flow demanded from a pulsator delivery valve; delivered thru an annular ring into the air stream.

In my minds-eye I see a system similar to an electric water well house system. A pressure supply tank buffering, replenished. A modern vehicle AC system. Cycling to refill, re-pressurize upstream of the expansion orifice.

Just paper napkin speculation on my part so far. Many of my best ideas flop for an unaccounted reason on my part. Only DOing proves.

S.U.

Turbo

Pressurized reactor

Put your gasifier in a salvage drum

Steve

I never got around to try this drum in a drum

Approach

Separate the hot portion from the pressure barring portion and I think it’s possible to teach those high pressure values I think will improve efficiency’s

Ha, that looks like a form of tesla valve…

Goran, thats exactly what l was thinking. I can see the pulses clearly in my BCS gasifier. Makes a lot of sence to me

That sounds interesting, like the old carburettor/turbo kit’s, where the whole carb was built in a pressurized box?

Yes i believe it’s inspired by the tesla valve, first i found about it was old ideas about tuning engines (four strokes) where the exhaust manifold should have a bigger diameter than the exhaust “holes” in the head, it gave the same effect, disturbing the back-pulse in the exhaust, less exhaust gasses blowing back in when exhaust valve closes, more evident with “evil” camshafts.

Hey guys I certainly wish there had been this active knowledgeable discussion back 10 years ago.

Just now reading this and looking now at pictures of offered up propane retrofit conversion kits onto my Harbor Freight 9500 inverter-generator I see I missed a factor. Put a cone gauze-metal screen type air cleaner on to the air-inlet side!! This will make a pulsation “wall” to reflect back from.

I did a lot 10 years ago trying to beat what a simple airbox mixer was doing.

Ha! I’ll still stand by most of what i said back then. Trying to beat the wattage out put of the simple airbox mixer pieces layed out on the white paper.

The final filter can attach picture shown to the hand-made brass throttle body was to final soot filter and pulse dampener. This was fed though a flex hose to a then remote mixer valve assembly. All, by then; brass/bronze, SS, and plastics.

Why I said be careful of your creations hanging on weights.

Mostly going forwards I take the woodgas exposure materials corrosions experiences from those 3 months winter project failure. An aversion to woodgas CO puffing back out the air mixer side into my face. And a real hate to be hovering hour after hour over an engine screaming along at 3600 RPM.

S.U.

Certainly not going to add anything knowledgeable to this discussion but despite much contemplation I still end up in the same hole. Wood gas is not like any other IC fuels. Propane and LNG are delivered pressurized from their storage container and from there the pressure can be further boosted. Because of the volume of air to fuel, gasoline or other liquid fuels can be vacuum vaporized or nozzle vaporized. Trying to pressurize WG in a plenum would require that the gas be pumped into the plenum at one point and the air metered in at another and anyway to maintain a functional stoich ratio would be daunting. Only option would possibly be direct injection of pressurized WG and a finely metered throttle body. This could all be horsecrap, but it’s the wall I keep coming up against.