I thought I would start a topic to see what others have dug up. It segways nicely into gasification since it is pyrolysis. Reverting plastic to oil. I’m of mixed minds about this one. Done wrong it can be an environmental disaster. Done right it can help reduce the ever increasing disaster that is plastic accumulation. Here is a link to a machine getting a lot of press a few years back until gas prices collapsed. Basically heat up plastics until it breaks down into oils, gases and carbon blacks. Anyways just kicking it off.

https://oceanlegacy.ca/faq-plastic-to-fuel-blest/

Thanks David i like idea of doing somthing cleanner with our envirement, if small refinerys could be built for single homes it would be better yet, since the transportation of mass quanitys of plastic would not be a cost factor. And as it is the recycle stuff ending in our ocians would end.Larger units for plastic factorys and clean up the dump locations would be good as well.Will the capitalist be inteterested ? Hopefully. I dont like ovet regulations but common sence clean up after ones factory profits shoulfd be manditory too the manufacures that profit from the sale of plastics.

I don’t know about house to house but certainly at a community level it makes sense. Again I would have to spend a good deal of time researching the thing. I think the offshoring of recyclables is a big problem. Plastics are relatively new to the world. Here is a report on Plastic roads in India: https://www.youtube.com/watch?v=uZDrk29TnZA

And a more high tech version in the UK: https://www.youtube.com/watch?v=cHWYoDKYnQo

I remember seeing this machine a while back. It seemed like it consumed a lot of energy to produce a little oil? What about feeding plastic into our gasifiers?

what are the potential problems? Is there a rule of thumb for safe amounts of plastic blended into our charcoal or wood chunks without gumming up the works?

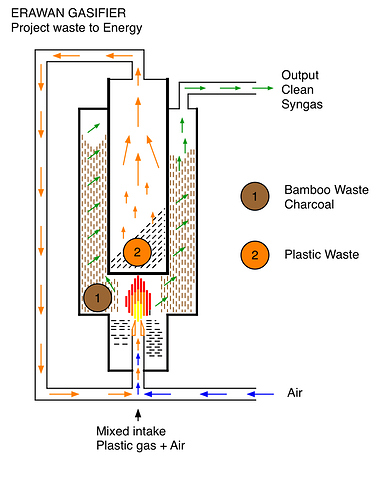

I did build this one for the school as teaching project.

It still can be used…

You can use the waste heat from exhaust or gas cooler to do the same plastic melting/pyrolising and mix the gas with your air intake from the gasifier.

You know what ? i will build another one… both raw wood and charcoal gasifier, each with a plastic module

I had forgotten that one Koen. I think the electric unit is far too energy hungry but gasifier heat does seems like a natural fit. I imagined a plastic layer in a tlud with heat recovery myself. Water heating or space heating in my case.

The plastic to oil does seem interesting. Could the ERAWAN be controlled enough to do the distilling?

Hi David , funny you should mention this now , we must be on the same wavelengh as i have been reading up on this for a few months now , infact i went to a meeting of local business that are buying a machine to do 10 tonn batches , takes about 6 hours from start to finish , but there is a lot more to it that first meets the eye . if anyone is interested in actualy making fuel oil / gasoline then this site is well worth reading , try getting past the first few pages though as a lot of silly questions keep getting asked

Dave

I don’t think i could use few words only to explain the difficulties of turning plastic into fuel.

Whatever you see in the internet of those so called plastics to fuel, its just nasty stuf… ( serious )

Compare it with: pouring all used paint dilution liquids from a paintshop together and get that in your engine… imagine the smell…

The only way that i consider more or less safe is: yes pyrolyse it, but only as hot that everything stay’s in gaseous state…

Then pass it thru a bed of glowing charcoal… ( all nasty and smelly stuff will be reduced to useable gas )

Stay far away from plastic that does not float in water, only use the plastic that floats ( PP, PE and HDPE )

If you have dry fuel for your gasifier, then you can ad small percentages of those plastics or build something similar as above , be it inside a gascooler or use exhaust heat.

If you use the clean LDPE foil plastic, you can insert the gas directly in your gas stream towards your engine, make sure not the liquids…

If you use one off above idea’s, then you gain the most off the plastic energy, without the need for disposing residue’s and without loosing energetic value’s per weight of the fuel…

Example reference: see Wayne’s testing with Auburn University… ( those numbers are more legit then any movie clip on youtube or any other article written and posted on the internet. )

Topic: if you want to turn plastic into oil ( not the nasty oil ) then use the total gasstream of a gasifier to make it into any pure liquid fuel by means of FTP ( Fisher Tropz Process) of any kind.

Koen with the design you show above do you end up with a buildup issue over time? I would assume there are some components of the plastic which won’t become a gas and leave that sealed vessel.

On a personal usage level I would suspect we could limit our plastic consumption to the point where we could just add the occasional bottle to a hot gasifer and not worry about it at all. Maybe I am wrong but that seems reasonable to me. When I had my Tarm wood gasification boiler I did this and never saw or smelt any bad side effects. But I do can my own vegetables in reusable glass jars so my plastic usage is very minimal.

It is actually pretty easy. You do fractional distillation. One of the first videos I watched on it, was from Ethiopia in essentially a hut. The blest just automated it a bit. You DO end up with a lot of heavier oil, and to do it well, and efficiently, it isn’t nearly as simple.

You #1 want to stay away from any chlorinated plastics like PVC period.

Regarding converting the oil back into a fuel for an internal combustion engine, it’s easier said than done. A friend had a re-refinery in Texas and it worked great… when it worked. He helped someone in Washington State put together a re-refinery and I heard it blew up. These were both industrial size facilities. Hopefully it can work better on a smaller scale.

For decades we designed solvents to be recycled as fuels. In this market, they combined waste motor oil, hydraulic oil and pretty much any hydrocarbon into a fuel oil blend for use in a large oil-fired boiler. So, it does go back to energy, just not for vehicles.

Heating oil is a lot heavier then diesel or kerosene. I have never done it, but you probably can use it in a waste oil heating system.

A lot of what they do now, is what Koen was saying and they crack it all the way down then recombine it using a FT process. They have a lot more control over the output products.

There is a project I think from Sweden that reforms plastic into like dimensional lumber types of products. You heat it up into a mush then press it out into your desired shape. I think I have it bookmarked, if anyone is interested I will try to find it. It was an open source type of project.

You can buy decking material from that plastic. A friend of mine built a deck with it maybe 20 years ago now. It worked great for a long time eventually it got really smooth with a roof over it it was ok but right out in the open I suspect it would get really slippery when wet.

The newer plastic decking is a LOT better then the older stuff.

I was wrong, I think they are based out of the Netherlands but here is the link:

Hi Sean,

Yes, this certainly a way to go. Even for us, the charcoalers, where we could use the waste heat to melt the plastics. Mixing the plastic with wood dust creates some nice “Woodplast”

" it isn’t nearly as simple." Says it all.

Making clean fuel from plastic is energy consuming and therefore considered " not profitable" hence less care for the envirnmental aspects. But… they never where thinking as we do… having energy available from gasification…

Plastics, the difficult ones, can easily be use as filler product in founndation concrete and other constructions. The soul reason why nobody does it? Where is the profit?

Hi Dan,

The build up is limited to some carbon residue.

I am doing some probes with the university, where i use the plastic module to cook the tar out, and try to find use for the carbon residues (very hard stuf) even to be used in graphene industrie.

So many things that are made possible once you get into wood gasification…

These guys are doing it in the US, and they even have the cement. They are claiming their diesel is competitive with 30/barrel oil. If I am reading this right they only do plastics US labeled 3-7. The EU plastic numbering is slightly different if i recall correctly.

http://www.renewlogy.com/

These guys do a bit more like tires and more mixed plastics, and end up with fuel as well as feedstocks for new plastics.

yup , these respolyflow people use the words " that can be" quite often…

Just another pyrolysis system… as there are 14 in a dozen …

I have 2 vehicles i run on used vegetable oil. One has been the experimental truck, lots of issues till i figured it out. The second on has been running 2 months with not even 1 issue, i only filter it and add one fiffth gasoline to thin the oil. Its not free but it only cost about 60 cent a gallon which beats 350 a gallon anyday.!!