Thanks for reply Rindert, i think that one deserves too be in the tricks thead,cool fix.

Now i found this pulley and its some form of sheave type pulley,not shur what type its called H type or not, cause it only has three bolts that pull the pulleys snug as it tighten on shaft. Most i see on line are two or 4 bolt type. This one is 1/8" too big for the standard 5/8" buget motor shafts that come on most 1 too 5 hp electric air pump motors. so im looking for the center section on line with 5/8" bore. Dont see any 3 bolt sheave center peice on line.Probbly too old pulley.

PS all the three bolt pulleys of this type are browning brand pulleys from KY.I have a Questain about pulley gearing, the inside demention is about 3" and the OD is about 4-1\4", do i go by the id or od of the v belt size.

Think i will he the streets for the scrap yards and see how many pulleys still on there junk motor piles. Too bad my latest vehicle aint on wood yet.

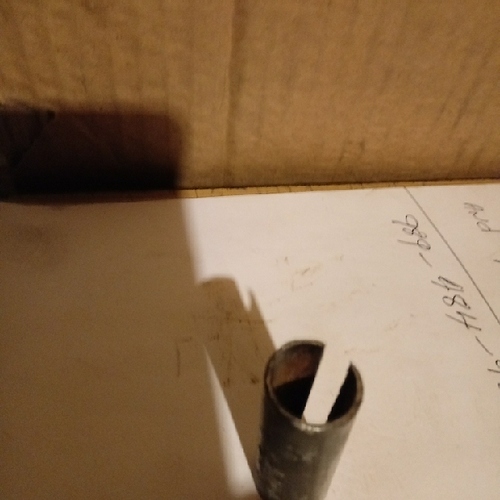

Well before i went scrap yard motor pully search, i had too see if i had any shims close enough too sqeese the browning pulley together, and the first steel i picked up was a 3/4" electricle conduit. And too my serprize after cutting a slot in it for the keyway it fit perfect after fileing away all the burrs. Had too tap it on the shaft and then the pulley had too tap on nice and snug before bolting the pulleys together, BOOM NOT A TINY BIT OF WOBBLE OR VIBRATION.hammer on pulley no movements nice and complete.

That 3/4" conduit makes perfect adaptor for 3/4" motor shaft pulley down too 5/8" motor shaft. AND THATS THE RITZ.Got pulley on strait, 2 belts on the way from jason industial inc. for ($20.03.) A77 4L790 size 79" x1/2" looked up on line says medium too heavy HP applications, should last a good size trailer full of chunked bag’ed wood.

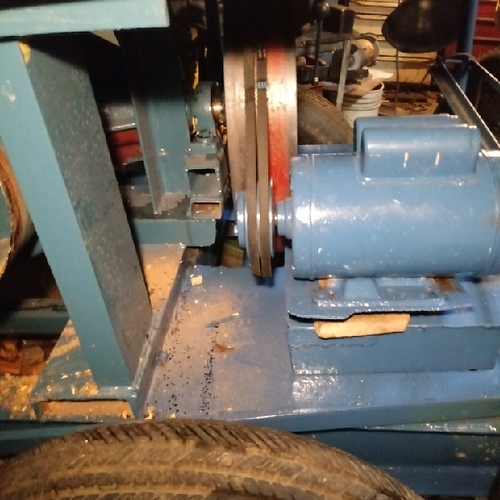

Belts working just fine, i slip the pulleys too start it, then let the motor down a bit too snug the belt up a little. Got my motor mount raised up and the hinge on the motor plate, started chunking wood, my 4" motor pulley is a little fast too reload on a single rotation, But its chunking better and faster than i thought would. WORKING GOOD.

That 5 hp motor seems the perfect size motor, not too small, hardly warmed it up chunking that about 100 pound pile in about 15 minuts.Looks Great, Kevin!!!  Wood chunking: no problem for you!

Wood chunking: no problem for you!

What a great job you did Kevin. That 5 hp motor must have cost a good chunk of change. TomC

Thanks for the compliments, im glad it pert near done, I am going out too build a flip out of the way gaurd around my wood splitter peg on the rotater, it rides too close for confert too the other cutter wheel. And cut some aluminum sheet i pulled from and old 29 foot camp trailer, thick enough too stand and keep the rain and snow from blowing up on the gear box when outside. All my aluminum sides are slide in and out for working or mainainance. i just cut another two barrels of slab wood took 45 minuts even, much faster than table saw, about 4 times, and a lotttt lessss nois.

Hi Tom Last 3 or 4 years i have been scaning the auctions 3 miles down the road, lots of old tools generators, air pumps, and all sorts of second hand garoge and house and car parts. I got that motor off an old air pump, cast iron end frames for around 30 bucks for the old air compressor. The other day i slid the end frames off the center section , And left the wires atatched,pulled the shaft rotor out and cleaned and regreased the roller bearing.

Great job Kevin

Small chunks and well shattered to dry quickly and burn hot.

Makes DOW much more fun

Thanks mike it sure makes chunked wood much faster than the axel chunker i built, The 5 horse motor and the flywheel and 8.5 too one gear worked out good speed and power too steady feed the wheel, made the gaurd for the splitter peg, and painted, pics tomaro if ain raining.

CHUNKER COMPLETE, Thanks for all the help decideing direction on building.I built a gaurd for the arm shreader or wood splitter peg.

Only thing left is an arm rest when i find best place too install.Any recomendations on pulley sizeing on the electric motor standard 5 hp mine is 3400 rpms. my 4 -1/4" inch PULLEY that i put the conduit in too use the pulley on an eith inch smaller shaft works perfect for useing, no vibrations, Though the speed is a little too fast too reload another 2 " of board before running out of time too set the wood peice at proper distance too cut next peice. so should i get pulley 3" or maybe 2-1/2" pulley too reduce the speed. Just wounering what kind of speed difference with the smaller size’es.THANKS.

It’s all about the ratio. Try to get the speed of your cutter somewhere around one revolution per second. Just checked mine 1750 rpm motor with 6 3/4 od pulley and a 8to 1 gearbox puts it about where I really like it. Chris S. runs a little faster than mine and he likes it but he is a younger man than I. Like Steve U preachs its all about what works for you

Hello Kevin .

On my chunker the cutting opening is wide open about halfway through the cycle . It stays open to give you time to get the wood into place and then makes a quick cut .

I think mine runs about 70 rpm.

Thanks for reply Tom W i have 2 or 3 of them 1750 heavy duty motors i can use if i roast a motor or anthing, i can use your pulley sizeing .

Thanks Wayne K on the rpms and the opening, if i had a bigger opening, i could keep the speed higher. i got too find out my rpms next i gess.Well i will check my stop watch next time running chunker thanks.

Turn the flywheel on the chunker by hand and determine how many revolutions per the flywheel to cuts of the chunker. That will tell you the ratio of the gearbox. Then calculate the circumference of the flywheel and the rpm of the motor will allow you to calculate the pulley size you need on the motor to get the rpm you want on the flywheel.