Rindert,

I don’t know if your question is about @Jan’s chunker or chunkers in general. I don’t have that type chunker but used a flywheel from a stationary bicycle for my rebak chunker, only because it happened to fall in my lap.

I think most of us would first if all use whatever we could get our hands on and secondly just try to estimate if the rear end, gearbox or whatever we’re using can take the torque and abuse of the flywheel coming to a halt. I’m not familiar to balers, but at least if you’re using a vehicle rear end the flywheel would spin 3-5 times faster than the cutting rim.

Yes, that is wath is told me too. Didn’t think that Palowna looked like that. A friend of mine has a real old one in his garden. Not so straight at all.

Well there are many vorietys. I know wich one you are reffering to, its more of a ornamental kind. But those straight vorietys are stupid fast growers.

Actualy, a guy just a few miles down the road planted 8" saplings in June? This year and today they are over 3 feet tall. I will post pictures tomorow if l remember to take them.

I am interested in them as well, partly allso because they flower strongly when mature. Bee stuff…

As for growing back from the stump, l know young ones do because years back here was only one woriety that culd be purchased and it wasnt wery winter hardy so people sugested cuting it down the first or second year to make it more hardy. With newer vorietys this seems to not be nessesery.

As for older trees, l dont know.

Althugh my mother did sew seeds years back and nearly all sprouted and turned to 10" saplings same year. So even replanting isnt a big deal.

She moved since then, l am curious how the trees are doing after all those years…

But allso, the fact they sprout so easy and row so fast is a potential recepie for a disaster. If this thing becomes invasive it wuld be a catastrophy. This is why l am still hasitant

This Serbian guy got it smart! He says he did cut it to the ground the first year for aclimatisation like l mentioned. But the wayl look at it, and the way he presented it, you culd plant it in alternating rows with corn on year 1, combine or silage the corn and pawlovnia to the ground, next year the pawlownia grows on its own and does so for the next 5 years. Harvest, repeat.

Couldn’t really see your drawing rindert, so I’ll just tell you from experience. Not sure about pulley sizes but I have motorcycle tires on my sawmill and they are filled with concrete or pourable grout to be more precise. I’d have to measure the pulley on the engine and on the drive wheel to get a ratio and of course the mill turns much faster than a chunker would but there was no balance issue with them. They don’t wobble. If the tire was totally filled and at the rate it spins I don’t think there would be an issue. I have a two inch solid shaft about five or six feet long. If I were to build one I would take the shaft and mount it in two pillow blocks. I would take the two inch shaft and add pipe sleeves until the shaft diameter matched the hub opening on a wheel, Set up a dial indicator and tack and smack the wheel until it ran true and then add enough weld to hold it. Being the junk yard builder I am, I would probably weld the same size wheel to the one with the tire on it and make some kind of flat belt to power if from another smaller pulley from the motor. I have a large cement mixer. It will easily fill a wheelbarrow and that gets powered by a one horse electric motor from a table saw. I think the motor pulley is about two inch and the drum pulley is 16 inches but it turns the drum about as fast or maybe a little slower that a chunker would. That’s my story and I’m sticking with it. Your millage may vary.

I like it. ![]()

Maybe I went off on a tangent before. Its been known to happen. I guess my main point was that a flywheel running at 540rpm stores 81 times as much energy as the same one running at 60rpm.

Rindert

Can you tell me the approximate dimensions of this flywheel and how fast are you making it turn?

I have thought about an exercise bike flywheel, but I have not found one yet.

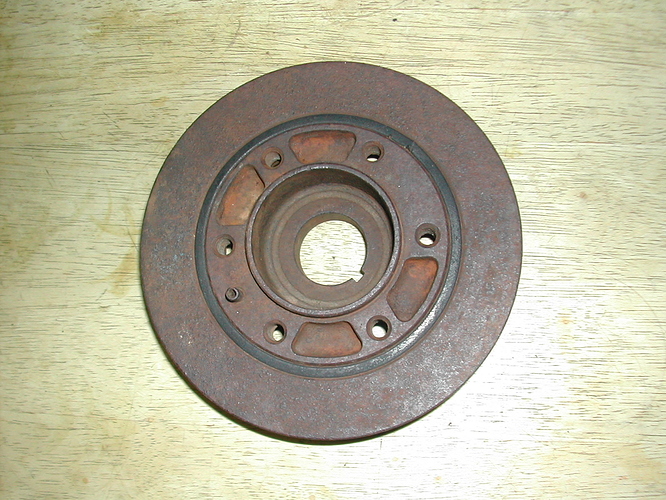

I have this old harmonic balancer from a big v8 engine, but it’s much too small. Maybe I could shrink a 20 lb (9Kg) aluminum ring onto it. It would be very good for removing very high frequency vibrations. But I feel ridiculous. I want to find a proper flywheel.

Rindert

It’s 12.5" in diameter and I guess the weight is 10-15 kg. Most of it at the very perimeter.

I clocked the cutter shafts to 108 rpm and the flywheel shaft turns about 4 times faster.

With 4 cuts per turn and 7-8 chunks a second the flywheel gets very little time to recover, but it’s still better than nothing.

This talk about using a tire for a flywheel with cement reminds me. If you fill the tire with a liquid (such as water with antifreeze), that will actually balance the tire for you. Nice smooth operating flywheel. TomC

Tom, unfortunaly that wuldnt work as a good flywheel because the mass isnt fixed to the structure. Imagine spining a glass of water around its vertical axis quickly. The glass rotates but the water does not. Same goes if you spin the water, there is litle force on the glass.

But your idea got me thinking, you culd fill it with plaster (hardens faster thain concrete) and spin for the time it hardens to balance it while it is still liquid.

Thanks Jan. This is very useful.

Rindert

Boy of all people, I hate to contradict you. BUT— within a few revolutions, the friction between the wall of the tire and the liquid, will cause the liquid to spin with the tire. At one time they sold hollow plastic tubes formed into a ring that were filled with a liquid. You snapped the plastic ring into the lip of the rim flange, to ballance car tires. Also, in farming we often fill the tires with a liquid to give the tractor more weight and better traction. (I sent my new tractor back to have the dealer put liquid in the rear tires-- the front end loader was tipping the tractor) Besides adding weight, the liquid makes the tractor ride much smoother when roading. TomC

Yes but same goes a nother way. It will take a few revolutions of water in the tire before the energy of water is fully transmited on the tire via friction, when the tire comes ag a sudden stop. But that defeats the whole purpose of the flywheel, to transmit energy imidiatly and smoothen the spikes in torque.

Yes! You make a good point. I guess the rpms of the tire would have an effect on the smoothing of torque spikes. After all, I don’t think anyone is planning on hitting a spike and stopping it instantly. TomC

I agree with that statement wayne, And any one that enjoys chunking wood should build a gasifier and feel the freedom of driveing without petro fuel.And its hard too beleive how simple the fuel control system works so well.

Been busy the last few days getting my mill going again and cutting some cherry. That is all about 4 or 5 foot long lumber.

Those are some of the more interesting grains I had.

I think I had about everything wrong I could when I started. Seems hard wood is harder to saw than just rough slab cuts of pine for siding on an old barn.

But a lot of troubleshooting later I am getting nice boards now. I am just glad I have the mill otherwise all this cherry would have ended up as firewood. While I could use the wood there is far less valuable lumber to burn.

I also sawed about half that amount in spruce the other day that cut easier then the cherry but there I was just going for construction grade lumber for my farm so not too fussy.

Those are the last 2 cherry logs left to saw.

Always check your cut depth on both ends of the log before you start. Or this can happen when you stop in the middle…

That wasn’t much fun. Turns out the sawdust behind the blade makes it hard to get out even after you wedge the cut open. Well there is a first time for everything.

Hopefully not always a second time though.

Just a fun photo of how a tractor is alway helpful.

There are a couple of photos of the cherry stacked in the top of the barn to dry. It can easly sit there until it is ready to use. Now if I only had a clue what I will do with it.

My first tree was winter of 77-78 spent the morning plowing snow. School from noon till 5pm work from 6 pm till 10pm.

Grabbed my grandfather’s chain saw and headed for the swamp behind the barn

where an old dead Elm tree was that I had scouted while rabbit hunting.

I felled that ole boy by the pale moon light

Almost 80 ft tall 3.5 - 4ft. diameter shook the whole swamp! Man that was scary!!!

Cut it into logs and skidded them out the next night. Yep after dark again. Yep working all alone. Lived with a bunch of drug addicted alcoholics. Family ! Being the youngest I had no say in that house. Wasn’t long had my own house. No drug addict freeloaders there!

I have cut many many more since then. Leaners and blow downs are the worst.

You need to study them first. Cut as many limbs off as you can. Safely! Then like Mr. Wayne says cut from the bottom as far as you can then from the top. If there is a root ball I used to stuff a big block of wood under the log then cut the root ball off close the the block

Even then things can go wrong

If so drop the saw and use your escape route.

All I can say is be careful the saw can be replaced you can’t!