I’m with Dan , I think the baler would be hard to beat .

Most of the balers have a shear bolt on the flywheel also that work very well. Don’t ask how I know this

I would think you need gear box . But you say you are going to use power take off . I spent $50,000

on pre built gasifier generator and grid tie . $4000 on wood chipper . and I think I should start over . It is just that bad .

https://www.gtmhongye.com/other-gearboxes/900.html

The rear axle end he has in the photo will provide a decent gear reduction from the 540 rpm pto. But it won’t protect the tractor from the impact force that is where the slip clutch and flywheel come into play they stabilize the load response on the tractor. An old baler is just a easy to come by example of this setup which will insure you don’t damage the tractor driveline.

I imagine it has been discussed somewhere here but has anybody made a chunker by just jacking up the rear end of a truck and driving it off the real axle.?

Dr Larry did once. I don’t know a lot of details about it. I know he had attached a pulley to the lug nuts that stuck out and ran a belt drive rebak essentially.

I would be concerned running a chunker on a small rear end if you care about it at all these things take a lot of beating I think you would beat the differential out of a rear end or break an axle on a light duty truck. I used 4, 5/8 inch grade 8 bolts to connect the hay baler gearbox to the chunker frame on my chunker. The two bolts on the top sheared because of the force if it will shear 2, 5/8 inch grade 8 bolts I think it will destroy a differential. You might do a traction/ friction drive running another wheel on the car tire using friction You might be alright but I wouldn’t do direct drive.

I don’t know this for fact and other guys might tell me I am wrong, but I would be nervous about trying this on a vehicle I still wanted to drive.

On another note if you run an engine on another single gearbox you have less Items that can break versus on a car or truck you are wearing out almost the entire vehicle to chunk wood.

I’ve never chunked wood so I don’t have any experience with what kind of stresses are involved. I have built drag cars and poured 600 horsepower into a Dana 70 and never broke one. I don’t have a tractor so no PTO available. I guess more research is called for.

Tom, I think, because wood chunking is so variable, you just need some device to take the shock of a sudden jam. On a drag car, your tires break traction and act as a “stress relief” for any sudden changes. It is more to protect the expensive bits of the system. maybe not ever needed, but can be cheap insurance. Kind of like those pressure reservoir thingys in your house water supply line to stop water hammer noise / damage. The wood chunker I envision has either a belt or friction drive line.

When I was doing industrial construction I could have taken home endless amounts of old conveyor belt. I have had a thousand things I could have used it for since. One would have been to make drive belts. We have an Old Engine show in this area. I have seen all kinds of things, mostly steam engines, that used leather belts to drive machines. The one thing all old machines had in common was huge flywheels. I was kind of thinking that using a jacked up car tire to turn a shaft with a large concrete filled tire on it for a flywheel would power a cutter through an two inch or less piece of wood pretty easily. Just speculation until I see where someone else built something similar.

If you don’t have a tractor yet I would look at some of the builds people have done using an old hay baler and mounting an external belt driven motor on the flywheel. The groves on the flywheel of a baler are designed for belt drive by a small engine for those who would rather pull the baler with horses. Don’t ask me to explain it not my religion but for some a motor running equipment but not driving the equipment is acceptable. All I can tell you is an old hay baler is usually pretty cheap and if you only want the flywheel and gearbox those are parts that seldom fail. It I was starting with nothing it would be the direction I would look first if you find an old enough one you will probably find the motor mount was actually included from the factory and the bracket is just sitting there never used.

It seems to work anyway, thanks Jakob and Wayne for the good advice.

Will try to find a flywheel as well.

Now we’re talking. That thing will require a video

Delicious looking chunks. Alder? Mountain ash?

I think the alternative is called plastic decking…

so I made wood chips and much less then half were correct size for wood chip gasifier . so I gave up on wood chip gasifier and stated working on charcoal for small charcoal gasifier .

I got a very good yield from waste with this screen

Had this oven sitting last five years . using it to make charcoal

stove pipe is spacer within can

You would think there would be steam , instead liquid , then burnable gas .

Pawlownia harvest in Bosnia. 5 years after planting. Its not exactly oak but even if the wood is super light such a harvest in such short time must make some sence in todays energy crisis???

What size flywheel would you use?

Had to ask the director for translating. Didnot know that it grows so fast, maybe faster then willow. The nice thing with willow is, you cut it and it grows again. This ones are cut and you have to plant again? Very fast grower. That is for sure. And straight. Nice for timber?

Tom,

I asked the question on here a little while ago: Truck Powered Chunker, would it work? I got a strong negative response from people here. But still, I think it could be done somehow. The exact setup on that thread wouldn’t work. I see that now. I think the speed would have to be reduced 2:1. I’m worried that your tire full of cement might be hard to balance. A flywheel from an old baler would have been made to turn at 540 rpm, and it seems that most chunkers turn between 60 and 120 rpm. I flywheel stores energy at a rate proportional to the square of its speed. 60rpm/540rpm=1/9 so a baler flywheel turning at 60rpm just isn’t going to be anywhere close to storing enough energy.

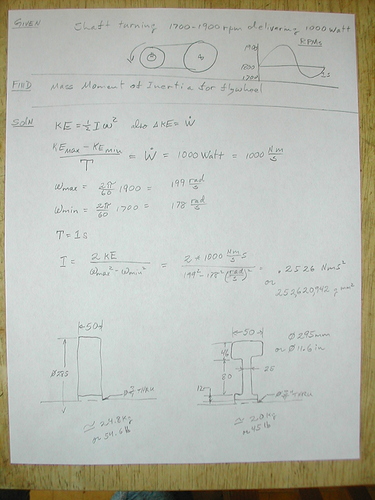

Here is a preliminary calc I did to estimate the size of a flywheel turning at 1800rpm. This is based on @Chris baler chunker video which he was powering with a 9 amp motor. Right now I’m thinking I could power with a 212cc predator on chargas.

Rindert

Ah, sure, your “director” certainly knows the translation better thain l do  l understand 80% of the language but still l usualy miss the important bits. And it just happened my Bosnian coworker wasnt on the shift today. I got most but failed to understand what was the exact reason why he harvested them at this age and not a few years later. He did say his main goal was firewood if l understand right…

l understand 80% of the language but still l usualy miss the important bits. And it just happened my Bosnian coworker wasnt on the shift today. I got most but failed to understand what was the exact reason why he harvested them at this age and not a few years later. He did say his main goal was firewood if l understand right…