Hi William , would that be a charcoal or wood side or cross draft unit your thinking of ?

Dave I calculated the exchange rate and that unit cost ~30% less in real value new than I just payed. And I was using a one time 20% discount code. Of course the bottom line did bump up by 8% for local/state sales tax.

Indeed. The way most treat small engine system sooner or later you’ll pick up one with a clogged injector; burnt out fuel pump; or weak battery/corroded cable ends unable to pre-cycle pressurize the fuel pressure.

Something was bothering me about his overall project. Woke myself up when it finally floated clear. He’s been cleaning up annual growths and burning or stacking aside. NOT power chipping to reduce chip to rot quicker. He has had no power chipper. Yet he designs and build a system that must have finely chipped wood the auger feed in.

A pretty big damn hole in his personal energy system.

Regards

Steve Unruh

If its anything like here in Victoria where i live he would be able to get a truck load of chips dropped off at the drop of a hat , there is so much wind fall damaged tree’s here where i am it brings tears to my eyes every time i drive past yet more fallen tree’s and limbs everywhere .

see if u can get a look on this link see what i mean .

Dave

I don’t think he is your neighbor. I didn’t have to rewind the video at all to figure out what he said. He doesn’t have the awesome thick accent that you can barely understand.

I liked his welding table. He must be one of those rich Aussies.

Yes Dave it loads up readable for this one article.

An event like this explains well why our English language has windfall-bonus; windfall-profit imbedded into it. A Disaster turned into a benefit.

You will seem wood rich for a time. Then, used up, bug infested rotted be right back to more realistic sustainable annual growths using.

Just like the sociologists children’s books, “Who Moved (stole) MY Cheese!” morphed combined with, “Give a Mouse a Cookie”, and he will ask for more, more, and more.

Attitude approach to problems is key.

Almost all of the chippy wood using guys get dragged into multi-motors automation just to keep things moving through their got elaborate systems.

Most; I think this is the intent. The Game. Ohhh. Automation motors controllers delights me so. Like the Robot Warriers builders.

But a few exceptions.

Stephen Abadessa at his Northern Self Reliance (an actual calculating Engineer) from a paid project saw the negative-net energy in pelltitized wood fuels. He woodstoves with chunk wood. Then wanted to small solar supplement; and back-up systems small electric generators fuel with wood chips from his sucker woods sprouts, end limbs and twigs like Mr Australia.

StephenA. developed the fuel woods chipping techniques in conjunction to his very unique simple six jets gravity feed gasifers. DIY use matched systems.

His make wood chipped fuel philosophies is summed up in this earlier video. A later one (now down) he did chipped wood fuel make with a small engine powered disc chipper somewhat modified.

Remember I’d said he was an actual Engineer - very familiar with the Garbage-In then Garbage-Out phenomena.

He and Canadian Greg Manning both learned and promoted ONLY gasifier fuel chip making in the winter in full sap down, no leaf. Even better if hard froze wood cells. Chips better with less fines they say.

Another guy who focused with his gravity feeding Chinese Gasifier maker system to get better results was to fine tune classify his wood chips - Frenchcreekvalley a DOW member active here in the past I think?

This one tells his Why the needs to classify sort. Later ones on his channel show his evolved automated wood chips/shreds classifier systems.

End useable percent yield using truck dropped off storms cleaning up ALL-chipped can be as low as 20-30%. Heck-of-a-lot of tonnage you have to fork your way through. Never again for me! That all mixed up green leafs, twigs and conifer needles is best used as muds abatement fill says I.

I’ll stick with chunked woods, thank you.

Regards

Steve Unruh

Not sure if this should go on the Global Videos or on this, but it needs to be shared. Based on a Gohin Poulenc

He’s ran a car with a scaled up version.

It is Charcoal fueled but since he’s having to add water I think he could blend in some wood. Wouldn’t know without it being in front of me.

Another guy using a Flashifier, I actually enjoy these long form woodgas videos, harder to hide any trickery. In his video description he says he managed to get out 3000 of the 5000 rated watts. He has a solar powered grid tie/battery backup electrical situation and uses a 48v PMA to charge on bad solar days. He also runs that on woodgas.

I like his chunker, too. Disc type.

Edit: It seems in his final mods, he had some help from none other than our Matt Ryder!

O.K. Cody. This guy was new to me. Watched all his videos now. Here is the best one I think: “48 volts DC . . . on wood gas”

One of his long, long ones because he does not edit.

I say his best because in his statement explanation and the then few comments Q&A’s below you learn he is doing this to supplement his existing PV solar; 48 volt battery bank in case of Grid down hurricanes in his Florida.

Already with PV solar; a controller; and 48 volt lead-acid battery bank why not just direct as possible DC charge. Then the engine could woodgas quantity/quality vary if he was conventionally DC alternator generating.

His belt driven PM, DC charging units? The few that I’ve seen need fairly close RPM to have a predictable output voltage. Permanent magnet fields and then no real easy way to boost or reduce the field strength for finite charging voltage control.

I know this will sound critical but a fellow just must absolutely keep in mind what he is trying to accomplish.

Way too easy on the parts of a home system to get led astray by others with different goals.

Wood to electrical watts it must always begin with the wood. No wood of your own then just stop.

Next jump to the electrical watts-maker. What is needed to supply your electrical consumptions demand? Do this next. Allowing for what you will need once you do have woodhgas. Will that watts-maker be O.K. with the SWMBO? The neighbors? (Damn his are noisy!). The derating and engines sizes, types are now well known. Select something common, repairable and replaceable.

Only then build-developed a woodgasifier to fuel that engine watts-maker.

And the better you do on the hearth-hopper core; the less downstream you will need to futz with. The better electrical generator woodgas systems only needs to use three downstream steps. Not 4-5-6-7. Those are for chemists.

Actually painful for me to watch a long one like this showing so much operator dependency on the woodgas systems. Then on the engine charging systems.

He says on this one he could only run a short time as lacking enough pre-dried fuel wood.

Stationary with all together right there close, his systems heats and engine air flows could be taking fresh cut 40% moisture wood down to 10-15%. Dry, dry fuel wood allows you to build simpler. Greatly eases the operators’ attentions times. Greatly eases the downstream maintenances. Gives a stronger stable gas production. Gives a better engine power equivalency.

I’ve only ever seen 2-3 fellows even attempting to use the operating systems shed heats do this.

Or even recognized the need, to be able to do this.

I am a monkey with a little drum who’s arms are tiring.

Steve unruh

I agree with engine exhaust wood drying. When I get a generator setup going I’m definitely going to make a drying cage.

I’m thinking a 55 gallon drum and make rabbit wire baskets for the wood to be stored in. Exhaust entering tangentially from the bottom up. Not sure if lid vs no lid would be any help, you’d at least want a stack for the moisture heat to escape.

Also I think Flash’s filtration system is more or less a hangalong from his FEMA experimentations. Giant cyclone “swirl cooler”, multiple coalescers in PVC standpipe bodies. Many many collection jars, another old hangover from YouTuber FEMA videos.

Yesterday I spent a lot of time browsing old Arvid’s posts. He always had a neat setup and everything was supposed to be there. But he had motivation, professional sale of gasifiers can’t have wasteful appendages or they’ll be wrecked from end user.

Found another one for you Steve , this one is from India and amazingly he has managed to do away with Tar as well , cast your knowing eyes on his drawings .

Looks like a double row nozzle gasifier to me. Perhaps like how JO or Tone has done, but he said he’s using 219mm pipe for the burn tube so it probably concentrates more heat for pyrolysis, less likely to let bad gas creep by.

Also preheating the air for obvious efficiency reasons.

Edit: as Stephen Abaddessa has said, no gasifier is 100% tar free.

He is not real clear on what he is using for fuel but it looks like big black chunks. Torrified wood that is almost charcoal? That would explain the low tar content of gas.

I think the gasifier featured in the Mercedes is stock footage that Lagunov filmed.

The gasifier in the drawing is made by a guy from India.

Yes I have seen this video.

Produced by a DOW member Sergei “Serg” Legunov. He in Ukrainian with his own youtube channel GenGaz.

He started this topic and others here on the DOW:

He asked us for reference help. Then later did produce and release that video.

Read that short topic thru to post #8 where he from his 600+ articles and books read has developed very interesting ideas on diesel engines woodgas converting. Well worth considiering.

Yes in this video the Mecedes is for sure his converted car. Like DonM saw the black wood chunks look to be heavily torrifed wood chunks. Note no dust pouring them in. Not charcoal.

The system (one of 2-5 he says low tar ones, he now knows of) I do not know the origins of this drawing. But do note that the 1st heat exchanger/dropping chamber would have probably forced air in and that then very highly heat boosted air goes into the gasifiers double row of air nozzles. Like a W.K does. That hearth tube very heavily insulated looking with internal refractory bricks? The second illustrated heat exchanger would have to have a forced air flow. And that indicated 70C outlet air from it then used for wood conditioning.

And he talks about nearly clear condensates. That talk plus the black block chunks sizing says this is not an actual charcoal gasifier.

But the blacked wooden fuel blocks, not raw brown wood and lack of hopper monorator features says not a raw wood gasifier either.

Him and other Ukrainians, and Russians I’ve talked to . . . along with some in South America, Africa, S.E. Asia are developing under different restrictions from us in the U.S./Cananda, even Western Europe.

So in my opinion he is not actually cheating using a pre-modified improved input fuel-wood. After all that is what charcoal is.

Regards

Steve unruh

He guys, just when it is big and black, it doesnt mean it is a Mercedes. I would go for Volga ![]()

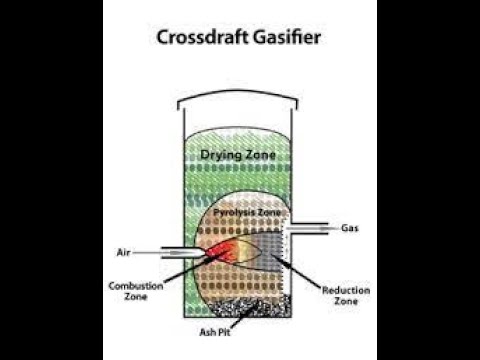

I want to say Lagunov uses a Cross Draft in his car. He keeps making videos about “transverse” gasifiers. Heavily torrified wood wouldn’t be a big surprise to me if that’s the case.

I wish there wasn’t a language barrier, he had incorrectly assumed how Matt’s gasifiers add moisture at the nozzle in another video, but I chalk that up to mistranslation or a lack of research and not malice.

Thats what it looked like when he dumped his bio mass in the hopper, that extra dryed wood could help most gasifiers make tar free gas. at leiste extra dry torrified wood would be less waist energy, and mass makeing charco, Other than the heat sourse torrifing the wood chunks, and that could be parcial from waist heat souse, or solor heater of sorts. Its time we start making more solar pannels here in the USA.

I converted his energy density figure of 1175Kcal/m^3 to 4.92 MJ/m^3. This is very believable.

Other energy density figures, mostly from @ChuckW.

Chargas 4 MJ/m^3

Woodgas 6 MJ/m^3

Retort made towngas 20 MJ/m^3

Natural gas 36 MJ/m^3

Pure propane 91 MJ/m^3 *note: this is not LPG, which contains some butane.

Rindert, interesting numbers, but we are most interested in the value of 6 MJ/m3, which would mean 1.66 kWh/m3, let me add another interesting fact that 1 kg of wood produces 2.5 m3 of gas and this corresponds to the calorific value of wood 1kg - 4.2 kWh. Well, we are very interested in what kind of power the engine develops on such fuel? If we take an engine with a working volume of 2 liters (a four-stroke engine captures the mixture every other revolution), which rotates at 2000 rpm and a mixing ratio of 1:1 (gas:air), it consumes exactly 1m3 of gas per minute (1.66 kWh of energy), this means exactly 100 kWh of energy per hour. If we take a motor efficiency of 30%, it should work with a power of 30 kW. This is very good power, my Fergie on diesel fuel does not achieve this, although the 2.3 liter engine develops a power of 25kW, let me state that modern petrol engines reach 40 kW on petrol. I’m going through the data and wondering where I went wrong,… ![]()