The main thing I have observed is the cyclone should not be a point where you are causing gases to drag because of restictions. This is why I built the gate type entrance that will open if needed. It closes on low gas demand and opens up on high gas demands, this keeps the gases spinning in the cyclone causing the particals to fall out.

Any extra gas drag in the system can work against you in your gasifier.

A example of this is in my 92 Dodge Dakota WK Gasifier. It should be able to run a much larger engine. But I have a restriction at the intake of the auto mixer. It’s gas opening is only 1 7/8" opening not 2" opening. Only a 1/8" is enough to limit my gasifier operation, if I open my manual add extra gas valve what a difference at highway speeds. It excellerates faster and I can get more speed. I am sure I could over pull my WK Gasifier with the manual valve open.

Now lets move that restriction to the cyclone filter area, it would be the same results of limiting the gas flow to the engine.

I am sure this was why Wayne chooses the drop box instead of the normal fixed opening intake of a cyclone filter when running a WK Gasifier. Less restriction of gases flowing at higher end perfomance.

This all changes when operating a charcoal gasifier, or I should say other gasifier designs.

My rule of thumb. Is this the restriction should be a the hot lobe of the charcoal at the restriction opening if you have one, or above the grate if you have one. Not in your filter area or intake opning of the engine or any where else in the gasifier system ahead of the hot lobe or after the grate area.

These are my thoughts on of what I have observed in my gasifier builds and my operations only.

Yours may differ.

Bob

So when the flapper gate closes on low demand, do the gasses redirect or does it just reduce the amount of gas coming in to still allow enough swirl?

The gate directs the gases to the outside wall of the cyclone causing the gases to spin down the wall of the cyclone the gases form a vortex movement as it goes to the bottom then the particals drop out as the gases slow down and vortex back up slowly into the exit pipe. When the vortex changes direction the particals fall into the bottom trap or holding area to be dump out later.

Bob

He was aiming for an easy build and was only get about 90% of the stuff. You can get like 99+% with a cyclone But you have to design it for the proper airflow, and they work best with constant velocity which is harder to achieve with a ice engine. Different velocities within the same cyclone will get different results as to how fine of particles it can remove.

For good cyclone operation, there is some math’s behind it, thus I was asking if there was a chart that went with it. ![]()

Sean, unfortunately I have to disappoint you, I saved this dimensional document years ago when a now deceased master designed a cyclone in the production process because there was a lot of dust and we had to change filters daily, the cyclone eliminated more than 90% of the dust. Unfortunately I don’t have the full flow data document, but I think if you have a 1 "tube reduce the dimensions from the sketch above 5x and it will work optimally.

No disappointment. I kind of figured that was the case, but was hoping it wasn’t ![]() Two posts prior to yours has a reference to a book with the needed calculations in probably a little more detail then needed to try and calculate. I’m sure most people don’t feel like doing all the math either.

Two posts prior to yours has a reference to a book with the needed calculations in probably a little more detail then needed to try and calculate. I’m sure most people don’t feel like doing all the math either. ![]()

I feel like 90% efficiency is more than acceptable given the simplicity of the construction. As long as it stretches out the time between cleaning intervals for my cooling rails and gives the bag filter an easier time I’ll take it. I more or less am just trying to prevent embers from burning the cloth of my filter.

Right, that is the trade off in a nutshell, and an explanation of the saying “the last 10% is 90% of the work.” ![]() I was really just curious if Tone had the cross reference chart. I was guessing no, but thought I would ask anyway.

I was really just curious if Tone had the cross reference chart. I was guessing no, but thought I would ask anyway. ![]()

Sean , if you download the file from Eddy Ramos, the information you are looking for is, for example, for a flow of 5.5 l/s, the inlet pipe cross section is 1". As far as I can conclude from this data, the velocity of the gases through the inlet is about 11 m/s. This is a key piece of information for sizing.

thanks to all for specific cyclone informations, needs time for me to open all because of very bad internet connection in the moment

ciao giorgio

first foto the provisoric foam filter mad from a honey can…

second foto, filter housing from aluminium and stainless…

third foto, filter on the engine, note excenter position of rubber hose fixing, this allows mounting in different positions and closure frame with centered pressure…

first try, the coal was a bit humid and some water stands in the main filter and also in the foam filter on the bottom…there was no dust on the throttle…

with really dry coal a little bit of dust goes also through the foam…

the foam is from a visco-elastic bed materass…

the engine was good to start.

the dust on the foto was from some hours working

the last foto shows the under part of the foam filter

emergency welding…i have read somewhere that in ww2 times people made welding electrodes by themselves with chalk mantle around, but nothing more exact informations…

has someone heard about or made experiences?

ciao giorgio

Technically, you can weld with a bare rod. The coating, creates an inert gas layer to prevent oxidation, and also has a flux in it to remove oxidation.

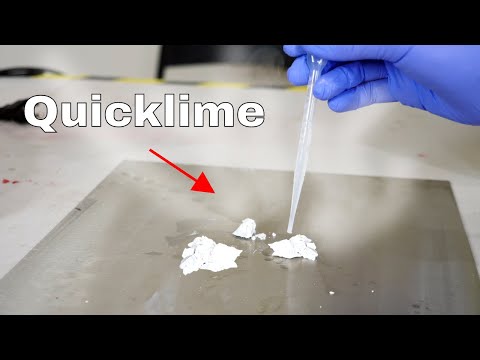

Chalk probably does work. Under heat it changes from calcium carbonate (chalk) to calcium oxide (quicklime) and releases CO2 in the process. And CO2 is commonly used as a shielding gas. I would guess as a flux, you could add borax, since they are both bases, and mix it into a paste or aqueous solution and coat them by covering, or dipping and drying like a candle.

Borax is used as a flux with pattern welding while forging, so I think it would work. A common household chemical too.

I remember an old blacksmith, that during blacksmith welding, he sprinkled the joint with brick dust, … he crushed a piece of roof brick with a hammer, … a mixture of clay and lime? Presumably this mixture could make good electrodes? Our chemist Kristjan would probably be able to explain this expertly.

I’m sure all that is right but I think I’ll just keep buying rod and vacuum sealing it. I’m going to have to research what was done when electric weld was first devised. I learned TIG welding in a motorcycle shop that built choppers. It was called heliarc then I guess because the shielding gas was helium. The welder was a large Linde machine. This was 1966. Amazing how much smaller and better welders are now.

Tone, first time l ever heared about brick dust. Many do however use silica sand.

I think a mix of chalk and borax is probably right on the money. But what to use as a binder?

My neighbour was specialized in aluminium brazing and told me they used to make their own brazing rods with diping alu wire in a slurry of some kind, borax based probably. Then leting them dry.

I think what l wuld try is thickly paint a slurry of 3 parts chalk one part borax on a peace of paper and try wraping that over the electrode. Making a kinda cigarette with a wire in the center.

I used to work in a shop where they made pressure vessels. We used a Submerged Arc machine similar to this. It was low cost. So I always thought; how can I use this in my garage? Can I coat that flux onto pieces of the wire? …

Rindert

the first coatings from the 1900s were clay or lime. Then 1907-1916, heavy coatings of carbonates and clays were used made by dipping then drying… Then later they added bits of iron.

I would lean towards clay as a binder given that is large group of hydrous aluminium silicates. the more modern industrial process instead of dipping, is extrusion. But it might be easier to cast them or roll it out and wrap it like Kristijan was saying.

It looks like they use kitty litter as the flux that goes between the arc and the metal, but it uses quite a few amps.

I felt smart for a minute when I downloaded the welding textbook, but it only goes to page 233 of 708, so I am only 1/3 as smart as I thought I was. ![]()