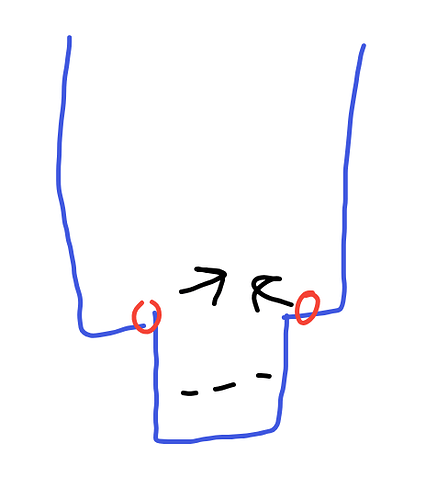

This design would really benefit from a more traditional downdraft feed system. Hopper that reduces to the burn tube, maybe put the flutes right above the burn tube which would be slightly smaller than the area between the flutes to prevent gas slipping past.

I agree fully with that , i missed out on a lovely square water tank a few months ago all stainless 16 inches square by about 5 feet high with a lid , it would have taken maybe 2 hours to convert to a fully working gasifier .

Yes i have also thought of welding a ammo can onto the bottom of a 44 gall drum and a design similar to what you just drawn

I have some length of 1/4" thick square tubing, it’s about 4" across perpendicular and I forget how long diagonally. I’m just afraid that would be too narrow. I would even go so far as to not use flutes and just weld in some small pipe, maybe 3/8" black iron, all feeding either independently or feeding into one air entrance. Maybe aim for flush with the inside walls of the square tubing.

Either that, or mount the flutes in the barrel above the square tube like in my drawing. I had just another smaller cylinder in mind in that drawing though.

Cody, what Dave sayd. This looks engine fitable to me. All its missing is fine tuneing.

Woodgas is not propane. Its slow. The fact that you werent able to reach a sustained flare may be just due to the gas velocity being higher thain the burn speed of pure chargas. A few % of hydrogen sped up the burn velocity for you.

A cruicial thing about any gasifier is for it to retain as much heat as possible. You WILL feel that when trying to idle. This means insulation. The way you have it now works just the same, internaly, as you skeched, but is way more insulated thain what you showed.

Ofcorse, if the goal is to use more of the barel height by adding on a firetube, sure, go ahead! otherwise its just ading complexity, and perhaps even more importantly, joints that can fail in the worst possible part.

A downdraft gasifier shuldhave no problem useing the water and making good gas. If you truely think water gets trugh your gasifier somehow, perhaps you need a restriction.

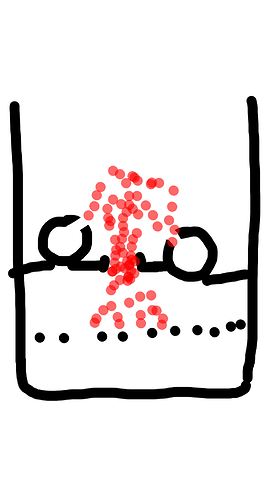

Perhaps something like this? Im just brainstorming thugh… But the point of a restriction is to concentrate everything, simply speaking, blend more atoms faster to achive good convertion.

I’ve been dicking around the last two days with this little up-draft charcoal unit I built. Same problem with the flare. Won’t sustain long without added water and I have to turn the ball valve on the three quarter pipe feeding the flare at least half closed as well. These guys are right. It don’t mean a thing unless it can do real work. . I’m going to hook it to the engine on my saw mill today to see if it will run that with the amount of gas I’m making. Keeping the greenhouse heated and getting plants started eats up a lot of time this time of year. Hard to put as much time into this as I’d like.

I’ll add a restriction and see how that does. I need to make more charcoal first though. I have the bottom of a steel drum I can cut a hole into as a restriction. The ceramic wool is acting like the burn tube but probably needs time to plug with ash.

I’m going to focus on building the rest of the gasifier first. Maybe that will control moisture levels. First things first is a cyclone.

I’m thinking of buying a 90 degree rigid conduit elbow, cutting it just after the bend and welding it with the bend facing the inside wall of a 20lb propane bottle to force spin, and to keep from wasting use the cut off length as the exit pipe. The bend radius might be too gradual though. I’ll see if my memory is deceiving me.

The drum bottom was riddled with holes so instead I found one of my spare junk brake drums. Has a 3" hole in the center, and I stuffed the sides with ceramic wool to try to make it more air tight. Also added more sheets around the flutes to force gas through the burn zone.

The hour long run that I did last night didn’t seem to use that much char. I had forgotten to shake the reactor to settle more down however so it left a bit of a loose formation.

Sounds like those changes are working!

Yeah I definitely think once I can handle moisture issues it will run the Mazda just fine. The roads here are shoddy so it’ll get plenty of shaking while driving. I can’t wait until I can plumb it in to the Mazda and see what my mileage will be like.

Cody,

Just another thought about your flare not staying lit. I think I’ve read of some having problems with their flare because of a poor gas/air mixture in the flare burner. Many flare burners are designed to mix air with the gas before the gas exits the burner with a flame. It may be notches around the top, a ring of holes around the circumference of the pipe, or even a larger piece of pipe spaced out around the gas pipe to allow air to enter in the same direction as the gas flow.

To me this looks great! Moisture problems will go away. Once the gasifier seals its self up. Only thing important is you finding the right way so that the flutes work as they shuld. Everything else is fine tuneing

I have probably the chunkiest cyclone ever. The in flow bends towards the curvature to try to force it to swirl. Exit pipe goes just a little over halfway. I made it so the original bung is now my drain/rinseout. I’m going to use a high temp silicone elbow to the cooler. And I will probably make a much shorter cooler. One that just goes up to the top of the cab and serpentines down to the filter. Filter will be a 55 gallon plastic drum filled with pine needles or hay, and an open cell foam cylinder. I’ll leave a fair gap in the drum so I can have a sort of reserve of gas for when I idle.

I’m welding with flux core so I know there will be leaks, that’s why I’m backfilling with Super Red silicone.

For stability of the cyclone I’m going to find a container that takes up the rest of the space to be level with the reactor.

I cant help but think the nozzles are pointing too high , help me out here clever people , now this is a down draft gasifier and so it is pulling from below , but that photo Cory put up with the brake rotor in the bottom shows that the holes are pointing upwards by x amount of degree’s , so in my eyes there is NO upwards lobe due to it being pulled straight down the edge of the lobe will cover the outer pipe wall on its way following the vacuum from below .

All the drawings put up have all showed a hot lobe pointing upwards and then being pulled downwards , even Kristijans drawing shows this post 185 but i cant see how the lobe would want to go upwards even for a milli sec if the pull was from below the air blast will follow the vacuum below .

Not trying to be smart here just how my logic is working is all , prove me wrong by all means , just thinking of Corys pipe work lasting ,as i really want this to work .

Dave

I can’t really explain it but in this situation my flutes are running cooler. Pointing down they will go over the temp range my infrared gun will read. I think pointing downwards it was blasting right beneath the flutes and heat rising to it. I’m betting it would be the same with pointing directly at each other.

On Joni’s wood units he points his nozzles upwards.

Running another test tonight. I don’t feel any moisture since I added the cyclone. Getting a purple flame. Probably blue core with light red skin.

It does not like the full blast of the fan so I have it probably a hair below halfway on my PWM.

UPDATE ON THE FLY: Flame has become more blue in color, but now some moisture is present. Less than without the cyclone but enough for me to feel it.

Cyclone is hardly even warm. Same for exit pipe. Gas is leaving very cold.

You are getting there Cody, on the tuning of that Gasifer keep working with it.

Good job.

Bob

Definitely going to need cooling tubes.

I stuffed a little cylinder of open cell foam in the burn tube so I know for sure I have moisture. I might angle the holes at a little more downward direction but not quite at each other. Maybe the jets aren’t meeting.

This go round the hottest my flutes got were 500°F