Ok here is the latest code update 5/26/23

The last update had some issues I must have missed. When you paste the code in the IDE the formatting was messed up. If you find errors, all you have to do is set your curser at the front of text (the IDE highlights when it finds and error) and back space. These are parts coments that our supposed to be ignored getting sent to the next next line. When it does that the forward slashes are not there for the IDE to ignore that text. So the IDE is seeing this text that is not actual code and it will return an error.

It will look something like this.

intconstant = 0; // this is example of the code

not pasting over to the IDE correctly.

Here is this corrected

intconstant = 0; // this is example of the code not pasting over to the IDE correctly.

Note how I had to bring the lower line of text back up to the line before.

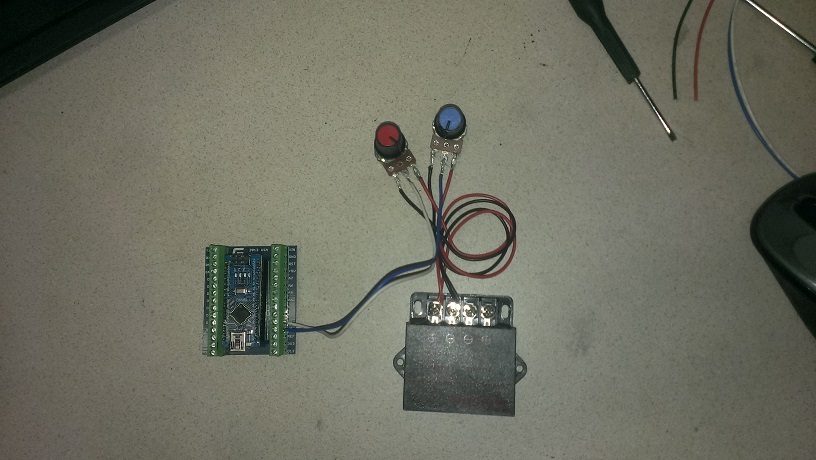

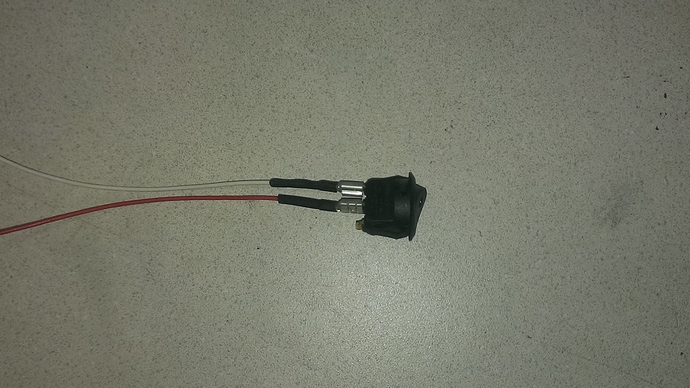

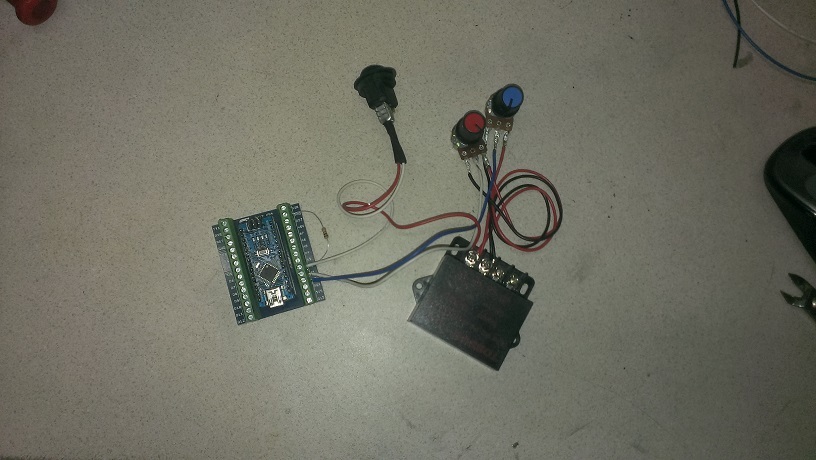

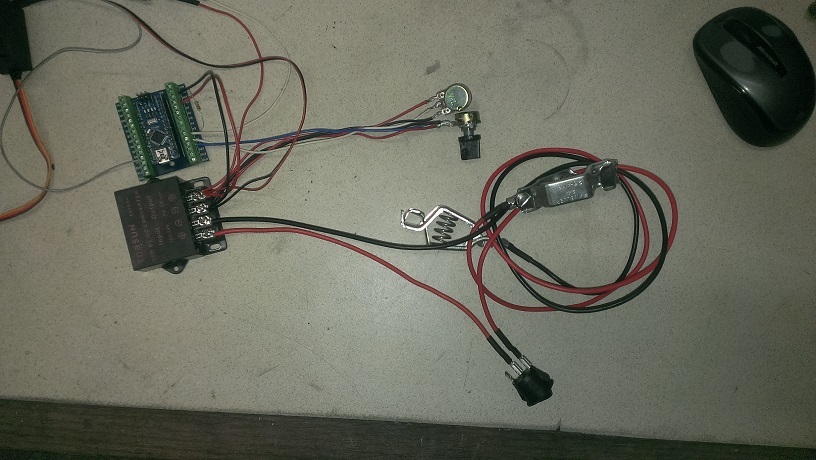

I made a change to this code as well. This code uses a momentary switche instead of an on / off switch. There is a feed back pin (D2) that can be used to eluminate an LED to indicate that the code has switched into automix mode. I use the “Angle Eye” switches and wire this pin to the LED terminal on the switch. You then only have to press this button to switch modes. The LED is either on or off. On its in auto mode and off its in manual potentiometer adjust mode.

#include <Servo.h>

Servo AFR_Servo; // create servo object to control a servo

//VG 02 Wide Band Mixture Controller V1.3

//Craeted by Matt Ryder, Vulcan Gasifier LLC / Thrive Energy Systems May 5, 2015

//website; https://www.thriveoffgrid.net/

//Prior edit; June 22, 2015

//Change log

//April 30,2017 - Todd Harpster

// added contraint to calculated delays after mapping to keep them in range

// read the O2 sensor just once per loop

// add table of expected delays based upon O2 sensor value

//April 30, 2017 - Todd Harpster

// v2 control loop

// refactored code to use mode variable and switch statement to

// This code requires an AEM O2 sensor kit with LSU 4.9 sensor Part # 30-4110

// These constants won't change:

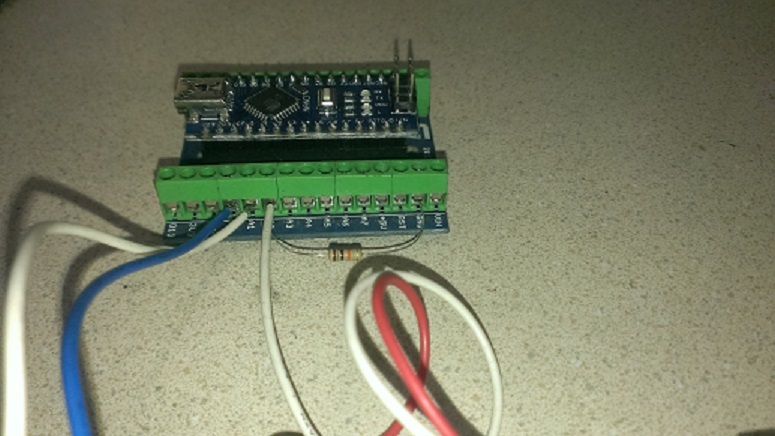

const int O2SensePin = A4; // pin that the O2 sensor is attached to

const int ModePin = A2; //Pin Auto Mode Switch is attached to

const int AFR_ManPin = A3; // Reads the O2 Manual Adjust Potentiometer on pin A1

const int ModeLED = 02; // Output pin to uliminate Mode button LED Status

// constants for our mode values

const int Mode_Override = 1;

const int Mode_Rich = 2;

const int Mode_Stoichiometric = 3;

const int Mode_Lean = 4;

//tunable parameters below

const int RichCon1 = 600; // Threshold limit for Rich gas condition

const int LeanCon1 = 750; //Threshold limit for lean gas condition

//Note make sure O2 Sensor Adapter Tube is long enough and creates sufficiant back presure

const int MinTuningServoPosition = 40; // never fully close the valve in O2 loop mode

const int MaxTuningServoPosition = 140; // wide open

int mode = 0; // loop operating mode

int pos = 0; // variable to store the servo position

int val; // variable to read the value from the analog pin

int lastpos = val; // variable to store the servo last position

int ModeStatus = 0; // variable for reading the Fuel Mixer Mode status

void setup()

{

//analogReference(INTERNAL);

AFR_Servo.attach(06); // attaches the servo on pin 9 to the servo object

pinMode(ModeLED, OUTPUT); //ModeLED Status assinged as ouput pin

Serial.begin(9600);

// Need to create a set point for servo start position after manual tuning

{

val = analogRead(AFR_ManPin); // reads the value of the potentiometer (value between 0 and 1023)

val = map(val, 0, 1023, 40, 140); // scale it to use it with the servo (value between 0 and 180)

AFR_Servo.write(val); // sets the servo position according to the scaled value

lastpos = val; // sets lastpos to equal the position of the manually set position

delay(10); // waits for the servo to get there

}

}

//

// O2 Sensor Reading Delay

// ================= ====================

// Manual 10

// Rich 0 - 700 variable 500 - 800

// Stoichi 701-899 500

// Lean 750 - 1023 variable 800 - 450

//

void loop()

{

// read the state of the pushbutton value:

//ModeStatus = digitalRead(ModePin);

// read the value of the O2 sensor:

//Todd - read the O2 sensor once for this loop and store in sensorReading

int sensorReading = analogRead(O2SensePin);

int ModePin = digitalRead(A2);

//variable to hold mode for this time through the loop

int mode = Mode_Stoichiometric; // assume O2 reading is not too rich or not too lean, just right

int delayms = 500; // 500 ms delay as a default value - it case it doesn't get changed below

if (ModePin == HIGH) {

ModeStatus = ModeStatus +1;

Serial.println(ModeStatus);

delay(100);

} else {

if ( ModeStatus >= 2) {

ModeStatus = 0;

Serial.println(ModeStatus);

delay(100);

}

}

if (ModeStatus == 0) {

mode = Mode_Override;

digitalWrite(ModeLED, LOW);

} else {

if ( sensorReading <= RichCon1 ) {

mode = Mode_Rich;

digitalWrite(ModeLED, HIGH);

}

if (sensorReading >= LeanCon1 ) {

mode = Mode_Lean;

digitalWrite(ModeLED, HIGH);

}

}

switch (mode) {

case Mode_Override:

val = analogRead(AFR_ManPin); // reads the value of the potentiometer (value between 0 and 1023)

val = map(val, 0, 1023, 45, 135); // scale it to use it with the servo (value between 0 and 180)

AFR_Servo.write(val); // sets the servo position according to the scaled value

lastpos = val; // sets lastpos to equal the position of the manually set position

delayms = 10; // waits for the servo to get there

break;

case Mode_Rich:

// move the air mixture servo to lean out by adding air

lastpos = constrain(lastpos+1, MinTuningServoPosition, MaxTuningServoPosition); // add 1 but make

//sure it stays in range

AFR_Servo.write (lastpos); // tell the servo where to go

val = map(sensorReading, 0, RichCon1, 50, 300); // Richer mixtures get shorter delay

val = constrain( val, 50, 300); // Keep values between 100 and 400 ms

delayms = val + 300; // increase delay so minimum is 500 ms - max is 800 ms

break;

case Mode_Stoichiometric:

delayms = 2000; // no need to move servo set delay to check back in 500 ms

break;

case Mode_Lean:

// move the air mixture servo to decrease air to make richer

lastpos = constrain(lastpos-1, MinTuningServoPosition, MaxTuningServoPosition); // subtract 1 but make sure it stays in range

AFR_Servo.write (lastpos); // tell the servo where to go

val = map(sensorReading, 1023, LeanCon1, 650, 800); // the leaner the mixture the shorter the delay - need to adjust quickly

val = constrain(val, 450, 800); // keep the delay between 450 and 800 ms

delayms = val + 500;

break;

otherwise:

//this shouldn't happen

break;

}

//wait for a little bit before doing this again

delay(constrain(delayms,250,1250)); // use contrain to be completely sure delay value is reasonable

}